The Omron C20K, C28K, C40K, and C60K shoebox programmable logic controllers have been discontinued since March of 2002. These Omron ‘K’ series PLCs were popular controllers and have been in installations for over 25 years. We will take a look at this Omron PLC and review some troubleshooting techniques. Planning for the eventual fatal failure of the CPU will also be discussed.

Find parts for your Omron K series PLC.

Manuals – Omron Troubleshooting

The following are the manuals for the ‘K’ series PLCs. You will note that the C20 manual is also listed. This is because the ‘K’ series could use the C20 expansion modules. The C20 was also referred to as a ‘Flatpack’ PLC.

Operation Manual – Sysmac C20K/C28K/C40K/C60K Programmable Controllers

https://www.lakewoodautomation.com/support/manuals/Omron/W146E15%20CxxK%20series%20operation%20manual.pdf

This manual will go through the instruction set as well as how to program the unit using the handheld unit. (3G2C7-PRO15-E)

Installation Guide – Sysmac C20K/C28K/C40K/C60K Programmable Controllers

https://www.lakewoodautomation.com/support/manuals/Omron/W147E31%20Cxxk%20Installation%20Manual.pdf

This manual will review the installation and troubleshooting techniques on this programmable controller.

C20 Programmable Controller – Sysmac C-Series – User’s Manual

http://www.edata.omron.com.au/eData/PLCs/Micros/W083-E1-5.pdf

This manual includes the installation, instruction set, and troubleshooting of the C20 PLC.

Hardware – Omron Troubleshooting

The K series PLC has very rugged hardware. Power supplies on this unit are rated for twenty-five years before failure. This is why we are discussing the unit and plans for upgrades.

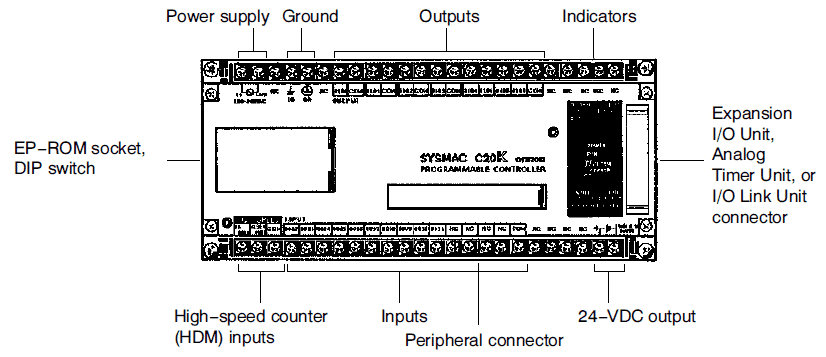

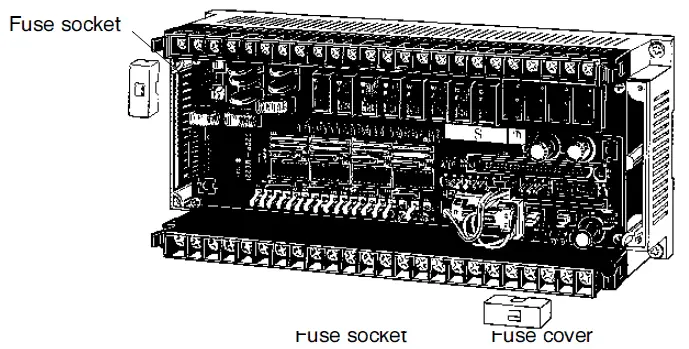

The above picture will show the components on the CPU base of each of the controllers. It’s important to pay attention to the indicators on the front of the unit. This will tell us the condition of the PLC.

DIP switches will control items such as language and program transfer from EPROM to RAM. Check your EPROM sockets to see if a chip has been placed in the unit. If so then your program is still intact.

Errors on the CPU – Omron Troubleshooting

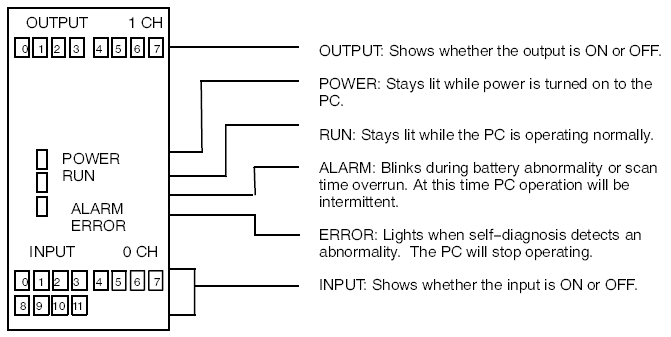

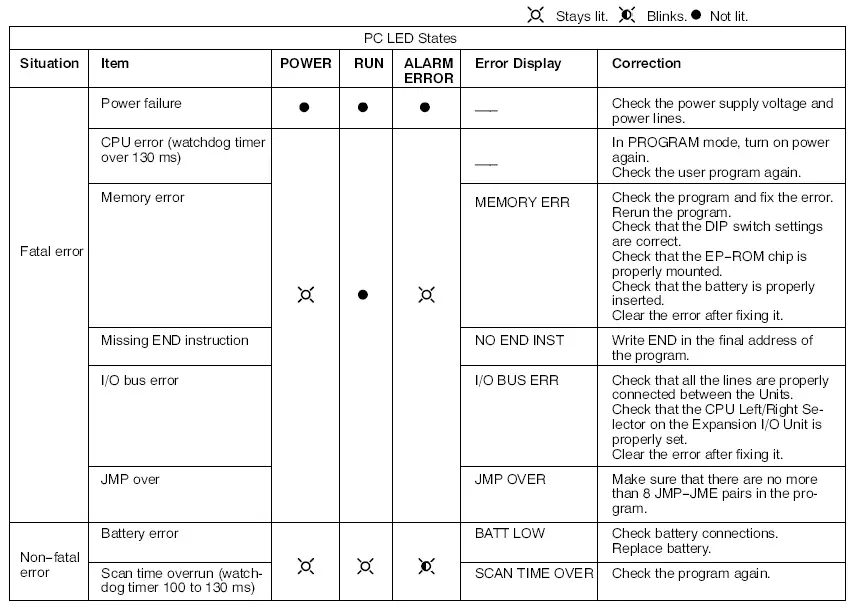

There are two possible error types in the PLC. Fatal and Non-Fatal.

Fatal errors will happen when the program or parts of the program have been lost. They can also happen if there is a power failure. (Fuses) The program will not run during a fatal error.

The non-Fatal error will still run your program. There will be a blinking error light to indicate the error. Typically this error is due to a battery error. (Battery needs to be replaced.)

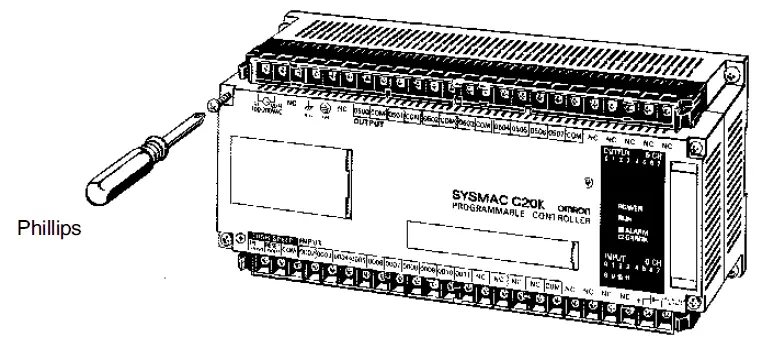

To access the components in the main unit of the PLC, remove the 4 screws on each corner of the PLC.

Note: When removing the screws and working in the unit, the capacitor that keeps the ram memory stored is good for 5 minutes. You should always start by having the power onto the unit to charge the unit. While charging unscrew the 4 corner screws. Turn the power off, and remove the top unit.

Fuse Change – Omron Troubleshooting

There are two fuses in the PLC. One for the incoming supply and one for the 24VDC power supply. They are fuse holders and designed to be replaced when needed.

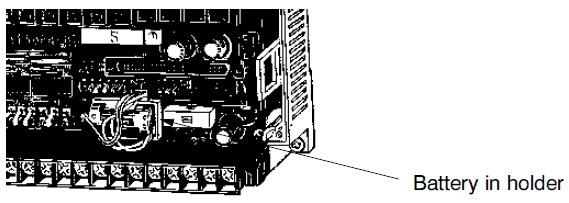

Battery Change – Omron Troubleshooting

The battery is in a holder and has a connector that will plug in. You will have only 5 minutes to change this battery before you will lose the memory in the unit.

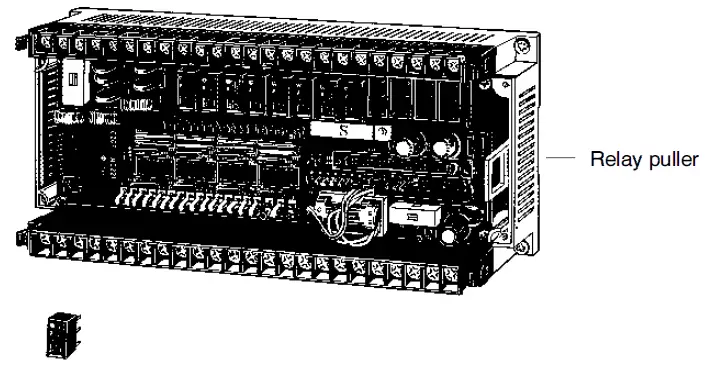

Relay Change – Omron Troubleshooting

Relay outputs on these controllers used sockets. This way the individual relays could be changed without replacing the entire unit.

Note: A relay puller was also included inside the unit to the right hand side. This allows you to change the relay without bending the pins.

Addressing – Omron Troubleshooting

The K series PLCs used a fixed address system. A maximum of 10 16-bit registers could be used for each CPU unit for the expansion I/O units added.

Example:

C28K-CDR-A (CPU 16 DC inputs / 12 relay outputs) + C20P-EDR-A (Expansion 12 DC inputs / 8 relay outputs)

Channel 0 – Address 000.00 to 000.15 – 16 DC inputs CPU

Channel 1 – Address 001.00 to 001.11 – 12 Relay outputs CPU

Channel 2 – Address 002.00 to 002.11 – 12 DC inputs Expansion

Channel 3 – Address 003.00 to 003.07 – 8 Relay outputs Expansion

Handheld Unit – Omron Troubleshooting

3G2C7-PRO15-E was the handheld unit that attaches to the peripheral connector on the CPU unit. This was one of the most popular methods to program the controller. A selector switch on the unit allowed you to select between Run, Monitor, and Program. To view any alarms on the controller, plug the handheld unit into the CPU. Ensure that the switch is in either Run or Monitor mode. (This will ensure that the CPU continues running if we have a non-fatal error.) Press CLR, MON, CLR. Your unit will display the error in the CPU.

You can see the entire operation of the handheld in the operation manual listed above. I also demonstrate the use of this handheld in the video below.

You can still get these units off of ebay or other locations:

http://www.ebay.com/bhp/omron-pro15

Software

Using a 3G2C7-LK201-EV1 (Host Link) unit which plugs into the peripheral connector you can communicate to a computer. The software that originally came out to communicate this way was LSS. (Ladder Support Software) This was DOS based and programs saved with this software used the extension .DAT. When windows came out you could use the Omron programming package called Syswin. Currently both of these packages are obsolete. The latest package is called CX-Programmer which is part of the CX-One software package. CX-Programmer will not program the K series or C20 PLCs. It does however include a CX-Programmer File Converter. This converter will convert your old programs done in LSS or Syswin to a newer format. You can then change your addressing to suit this new controller.

Future – Omron Troubleshooting

Your Omron K series or C20 CPU will fail. To ensure that you do not lose your logic for a machine, I would verify that you have a copy of the program. This copy can be the list of mnemonic codes, written down from the handheld unit or a program in LSS that has been converted to CX-programmer. Ensure you take steps so the program will not be lost on a fatal error.

Find parts for your Omron K series PLC.

Watch on YouTube: Omron C20K, C28K, C40K, C60K Troubleshooting

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.

Hi Gary,

Thanks for the great article.

I have a customer with a C40K and no backup of the program. Do you know where to find the 3G2C7-LK201-EV1 as Omron has discontinued it long ago?

If I was to use the PRO15-E how time intensive is it to convert the mnemonic codes into standard ladder logic? Does this controller have proprietary mnemonic code system?

Hi Kris

You can still buy these units on Ebay. They go from $500 to $1000 CDN. You can try to contact your local Omron representative and see if you could borrow a unit. Using the Pro15 unit is not a bad option. It is straight forward to convert the mnemonic code to ladder. If you send me the code, I’ll help you convert it.

Regards,

Garry

Thanks Garry,

I’ve contacted the representative in my area. If I was to need help converting the mnemonic code to ladder how would I contact you?

I have contacted you in a separate email. If you need any help, please let me know.

Thanks Kris

Garry

Hi Gary I have a custom system that used a sysmac C28K omron PLC controller that went into cold storage for a long time. This system needs to be setup again. I got everything cleaned up and tried powering up. The PLC goes into an alarm right away. I took it apart and replaced the battery on it. The battery melted in place long time ago. I don’t have a backup of the program that was loaded. Do you think the program is long gone or it it stored on an EEPROM on the controller and all I have to do is clear the alarm?

Hi Sophronis,

The C28K did not come with an EEPROM option. It could only have an EPROM chimp installed under the left panel on the main CPU unit. If the socket is empty then it does not have any backup.

The flashing light is an alarm light. This is good because it means that the unit is still functioning.

Do you have a handheld unit? If so then attach it to the CPU. Select program mode. Hit CLR MON CLR keys in that order. This will clear the error alarm.

Regards,

Garry

Garry how can I get a hold of you? I have an Omron C40k . The battery died years ago. I replaced the battery, but of course I have an error, light on constantly, so I need to clear the error. However I do not have a hand held unit to clear the error.

Not sure where to get one or if it is worth it getting one to clear the error.

Hi Greg,

I believe your program is lost. The error light is probably because there is no end statement in the program. The unit is probably still functional.

A quick ebay search will bring up the unit that you will need to program:

Omron Pro15E Handheld Programming Device

The part number is a 3G2A6-PRO15-E.

You can email me at garryshortt@accautomation.ca.

Regards,

Garry

Hi Garry!

Thank you indeed for your dedication to everyone’s knowledge. Outstanding example on these days…

I have a question about a C28K: I have one working with a old batterie and no EPROM or other backup of the program. I read on the manual you kindly pointed that the PC is able to clear an EPROM if the respective switch is ON… thus this means it is possible as well to write the program on it, I mean in a “upload” command or so? That would produce the wanted program’s backup…

Thank you once again, Garry… BIG cheers.

Hi Fernando,

Thank you for the comments.

A Graphic Programming Console (GPC) is the device that you are talking about. I have not seen one in about 25 years.

The best way to save your program is to use software on your computer. (LSS or Syswin) The computer will talk through a serial port to a host link unit that mounts on the K series CPU. The host link unit is a 3G2C7-LK201-EV1.

Another way would be to use a CPU mount unit with a keypad. Pro15 unit or something similar in the video above.

Unfortunately you cannot write the program to an EPROM mounted in the CPU.

Hope this helps you out.

Regards,

Garry

Hi Garry,

Thank you for posting this knowledge!

I have a C28K which I would like to replicate. It does have an EPROM mounted. Would it be reasonable to burn a copy of the EPROM using generic hardware, and then install the EPROM in another C28K to generate the replica?

The next step would be replicate the function using a more current model of PLC.

Best Regards,

Tim.

Hi Tim,

https://accautomation.ca/purchase-find-parts/omron-c20k-c28k-c40k-c60k/

Since you are going to be replacing the PLC system, I would get a handheld programmer. (Pro15-E) This will allow you to read the existing program and copy it into another controller. You could burn another chip if you have the equipment, but using the handheld would be the most cost effective solution.

I’ll help you to convert the existing mnemonic code from the handheld programmer to ladder. (garryshortt@accautomation.ca)

Regards,

Garry

Hi Garry

“We have an Omron C60K controller. The RAM memory battery was depleted. Fortunately ROM is installed. After battery replacement, how is memory loaded back into RAM? We searched the web and read the manuals several times. If we could have some direction it would be very helpful in restoring this legacy equipment.” From reading I think it is accomplished by the dip switches? Thanks for any help.

Hi Ron,

You are correct. The ROM is activated by the dip switch settings.

Installation Guide

See 2-8-1 Setting The CPU Dip Switch

1 – Turn power off to the CPU

2 – Remove the cover from the CPU

3 – Set Dip Switch pins 1 and 2 to OFF, pins 3 and 4 to ON

Note: The battery will hold the program (RAM) and memory retentive areas in the PLC. This means that you may still need a battery for the retentive memory areas.

I hope this helps you out.

Regards,

Garry

Hi,

I have a C28K in control box that runs a hydraulic pump to a Muffin Monster at sewer pumping station. As I recall there was an issued that was fixed probably 8 yrs ago with the unit we have, however I don’t recall the fix. Some strange behavior with oil temp and oil pressure warning lights and complete shut downs but our electrician couldn’t pin point problem in other electronics. I’m wondering if the fuses or battery inside the PLC was the fix before. The PLC has the same stickers or stamps as in the original control box itself so I don’t thing the replaced the entire PLC.

What type of battery does the C28K have in it and what type fuses would expect to need to replace any faulty ones.

Thanks for any input.

This is all new to me.

Hi Doug,

Here is the installation guide for the controller.

http://omronkft.hu/nostree/pdfs/plc/cxxk/w147e31_c20k_c28k_c40k_c60k_installation_guide.pdf

Section 3 – Maintenance and Inspection is on page 45.

If you have a flashing error light, this usually means that the battery needs replacing.

Battery: 3G2A9-BAT08

Fuses are listed in the above manual. This would usually mean that you would not have power to your cpu or outputs.

Relay units can have individual relays replaced. If an output light is on but the actual output is not switching you can replace the relay. G6B-1174P-FD-US

I hope this helps you out.

Regards,

Garry

Hi Garry

Thank you for helping community.

We have a C20 with Power LED on, Run LED off, Fault LED on.

Program is in RAM, battery is Ok but we nevertheless suspect lost of program.

We have no console nor other tool for further diagnostic.

We would like to try ROM program instead of RAM.

1 – I understand DIP switch setting but I don’t know if ROM chip is present.

There are 3 memory chips on CPU board (as shown in doc) :

– left one is RAM and soldered directly on PCB

– meddle is an empty socket

– is the right one the program ROM ? or need to put an EPROM in meddle socket ?

2 – We have a Syswin copy of the latest program (*.SWP file) but we don’t have Syswin to convert it in an binary image in order to burn an EPROM. Can you convert it for us by e-mail ?

Thanks again for your help.

Best Regards

Claude

Hi Claude,

The EPROM 28Pin socket is located on the lower left side of the board. See page 2-2 of the following manual.

http://www.edata.omron.com.au/eData/PLCs/Micros/W083-E1-5.pdf

You would require an EProm burner.

I can take your *.SWP file and convert this to a ladder program and the three types of EPROM burning files.

http://www.edata.omron.com.au/eData/Software/Windows/Syswin%20V3_4%20Operation%20Manual.pdf

See producing EProms on page 9-4 of the above manual.

My email is

GarryShortt@AccAutomation.ca

Regards,

Garry

Hi,Mr Garry

Thank you for helping community.

We have a plc OMron sysmac C20 with Power LED on, Run LED off, Fault LED on,hardware problem happened, after repairing i need to reset ,unfortunately i do not have programming console ,is there any other solution to make reset without programming console,i appreciate your help,

Hi Anis Bettaib,

Based on the indicator lights, I would say that the PLC has lost its program. Do you have a copy of the program?

If you do have a copy of the program, you will need to re-enter it into the controller. The best way to do this is with the handheld controller. This can be purchased on eBay.

https://accautomation.ca/purchase-find-parts/omron-c20k-c28k-c40k-c60k/#Peripheral

The handheld will also provide the error details. This will give more information on the error besides the indicator lights.

Regards,

Garry

Thanks a lot Mr Garry ,I don’t have copy of program but we have other machine same model,can we extract the program from this machine , make a copy and reenter to the damaged PLC,last question Mr Garry the plc model is C20,wich type of handheld i must use , and can i use same handheld of C20k,

Thanks and regards

Hi Anis Bettaib,

You can use the same handheld as I mentioned before. I would connect the handheld, manually copy the program and then use the same handheld to then load the program manually into the old PLC.

Here is a link for the handheld.

https://accautomation.ca/purchase-find-parts/omron-c20k-c28k-c40k-c60k/#Peripheral

(3G2A6-PRO15-E)

Regards,

Garry