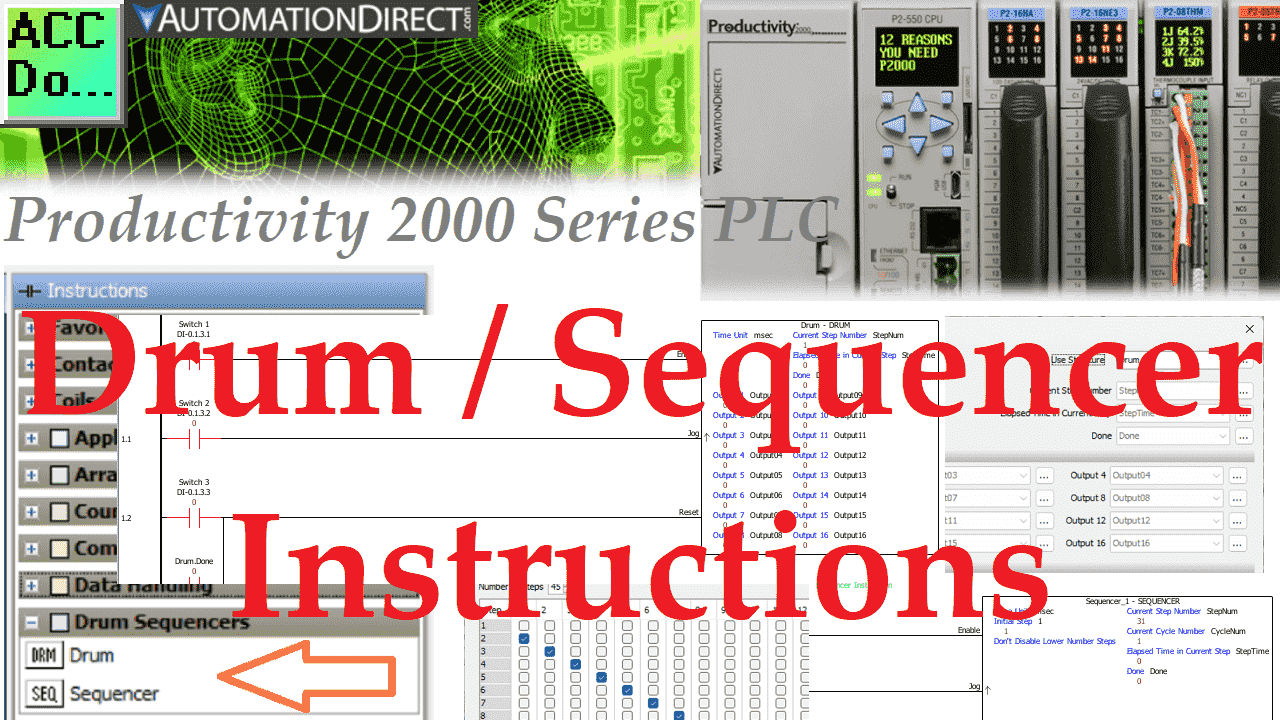

Productivity 2000 PLC Drum Sequencer Instructions

The PLC productivity series includes a Drum and Sequencer instruction that can be very useful. The Drum instructions function similarly to an electromagnetically-operated drum sequencer. To better understand this concept, consider the mechanics of a music box. A small drum with pegs catches and flicks the chimes in a specific sequence to produce a tune. … Read more