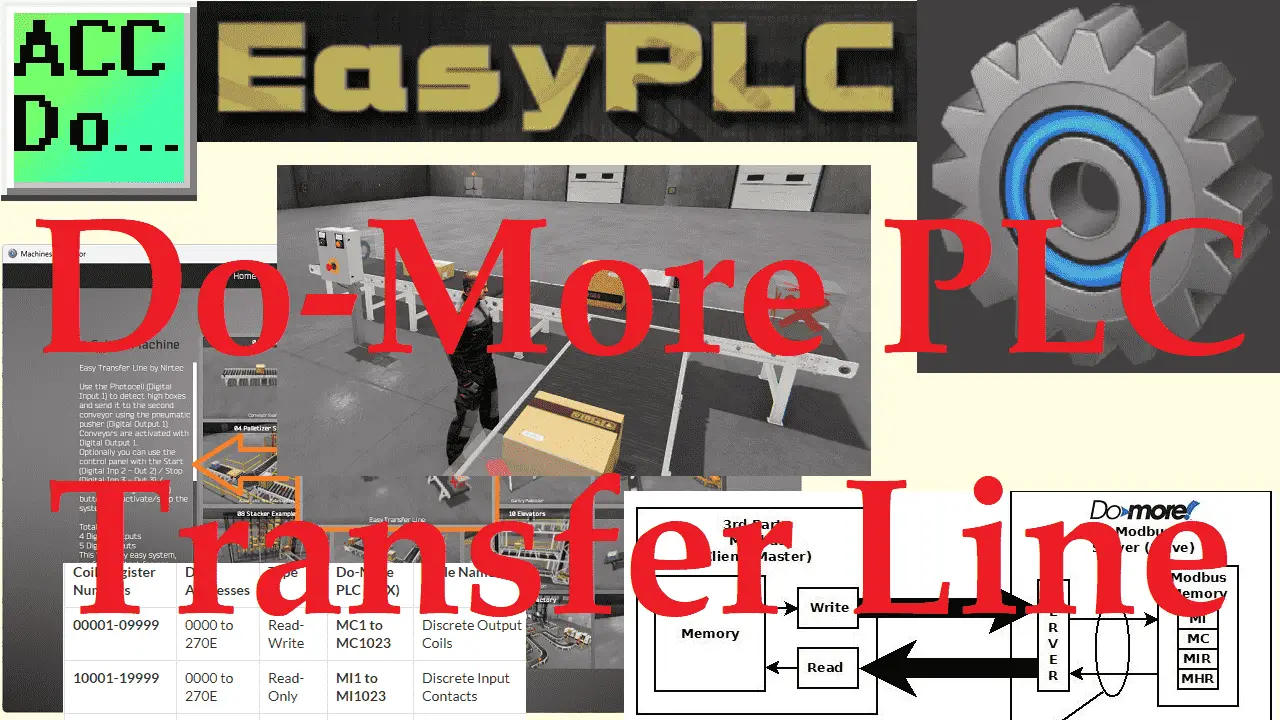

Streamline Programming Do-More EasyPLC Transfer

The EasyPLC Software Suite is a comprehensive package with PLC, HMI, and Machine Simulator software. It features a Machine Simulator (MS) that allows virtual communication with many programmable logic controllers (PLCs) in a 3D world with real-time graphics and physical properties. Our PLC programming example will follow the five steps to PLC program development. We … Read more