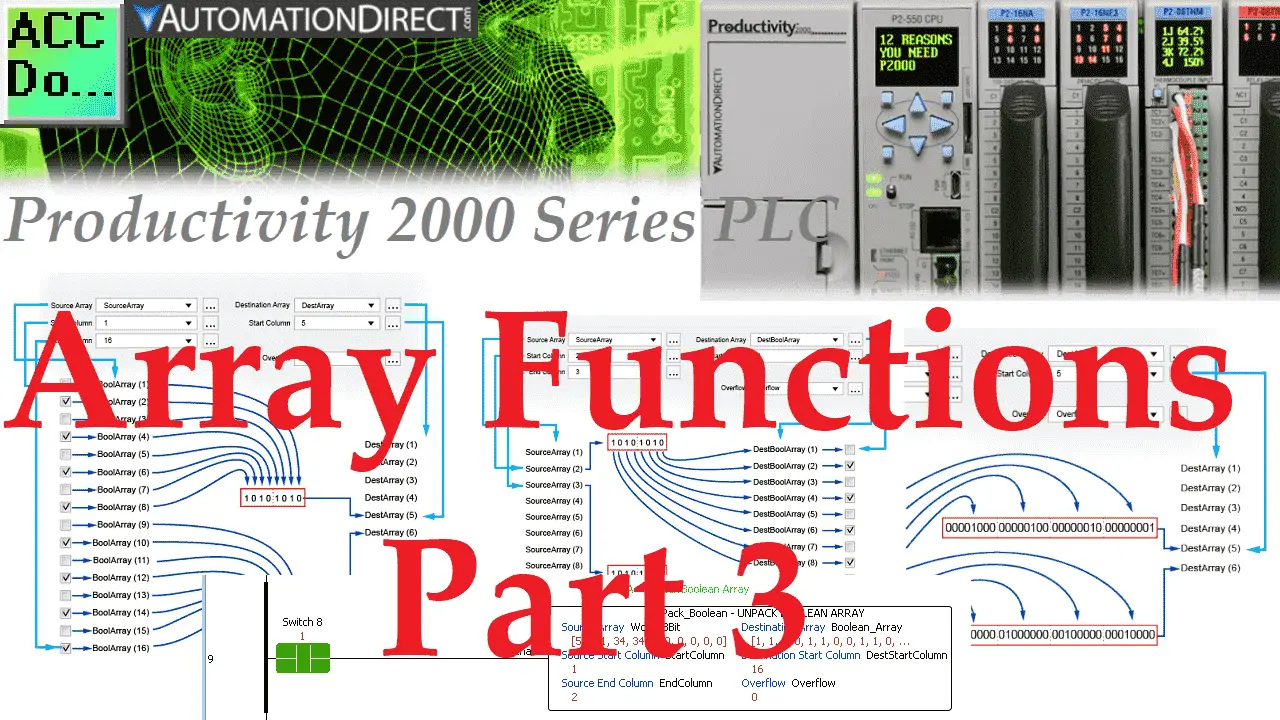

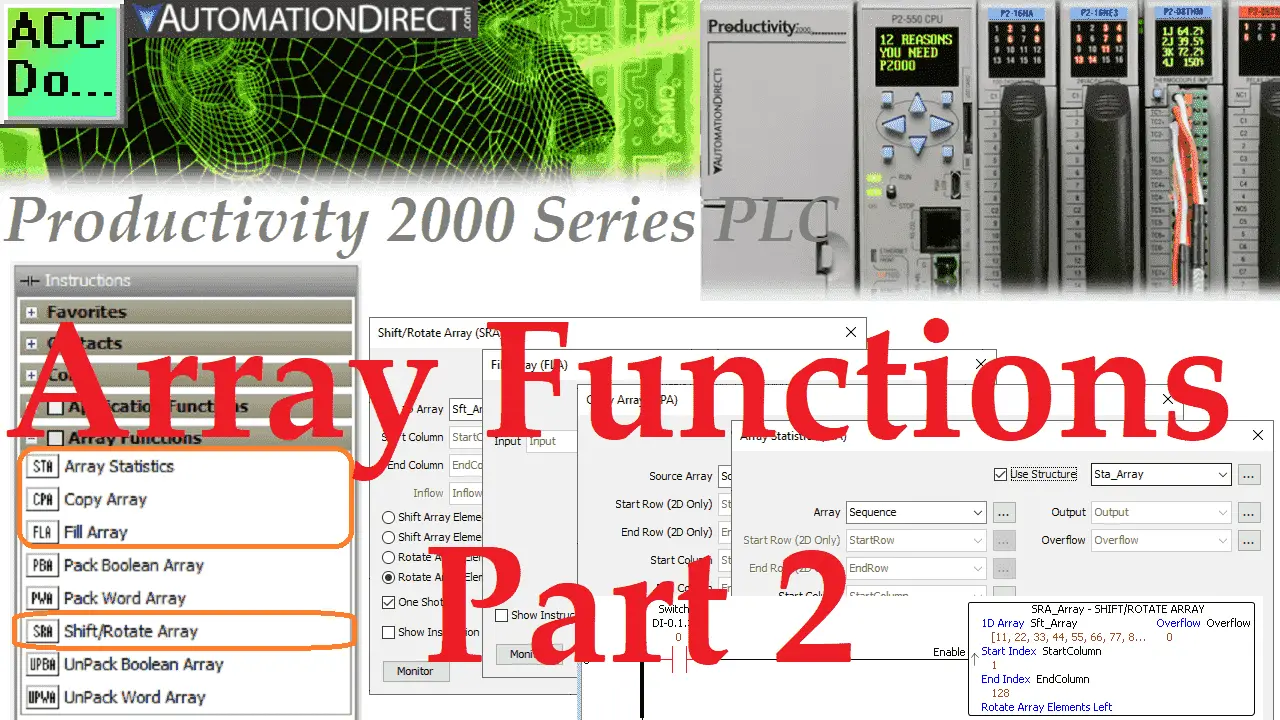

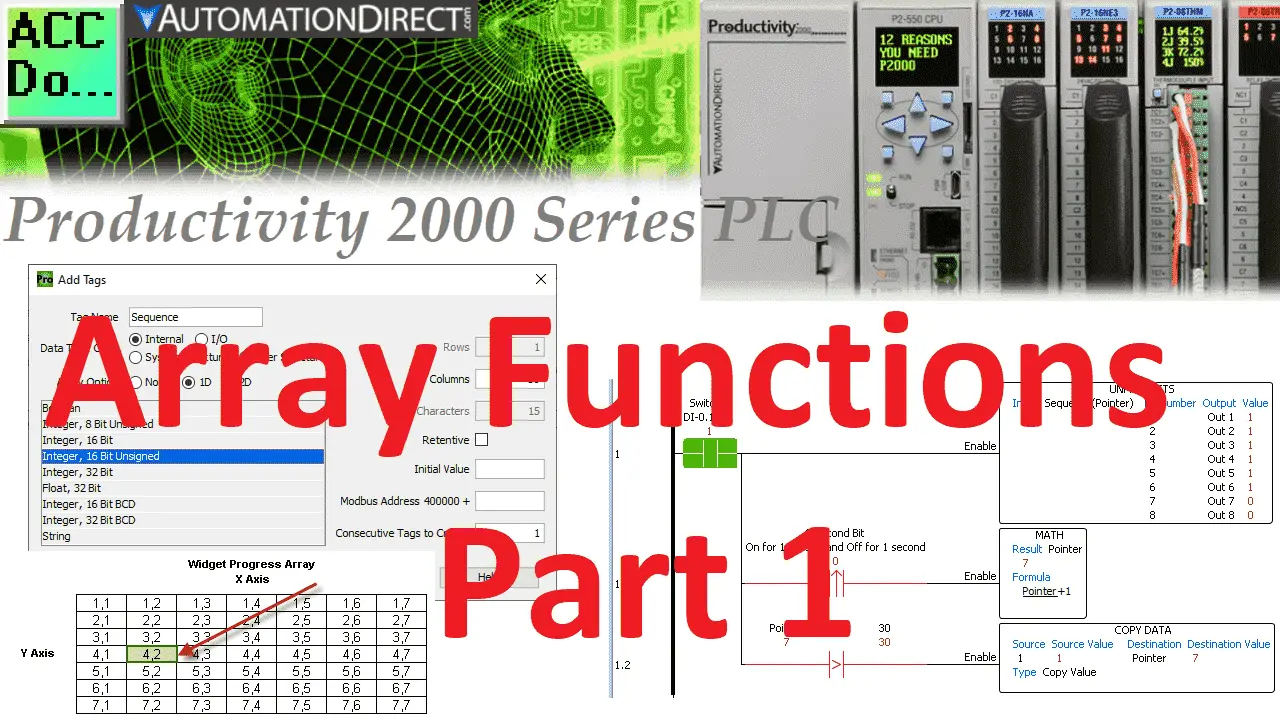

Productivity 2000 PLC Array Functions Part 3

An array is a storage area for common data type tags. They usually have some relationship with each other and must be manipulated as a group. We can use arrays for motion control, recipe management, sequencing (indirect addressing), math, etc. The Productivity 2000 Series PLC uses arrays programmed using the Productivity Suite Software. Previously we … Read more