Accelerate Learning …

Accelerate Machines…

Accelerate Knowledge…

ACC Automation

It is a good time to be in the automation business. Technologies are merging and communicating like never before. What was impossible is now possible for the industrial plant floor. We are looking forward to the New Year and new possibilities for implementing your control solution.

Each year we like to take a few minutes and reflect on the past, current, and future of ACC Automation. You have helped us to build the site that you see today through questions, comments, and suggestions. Thank you.

2019 has been our best year yet thanks to you.

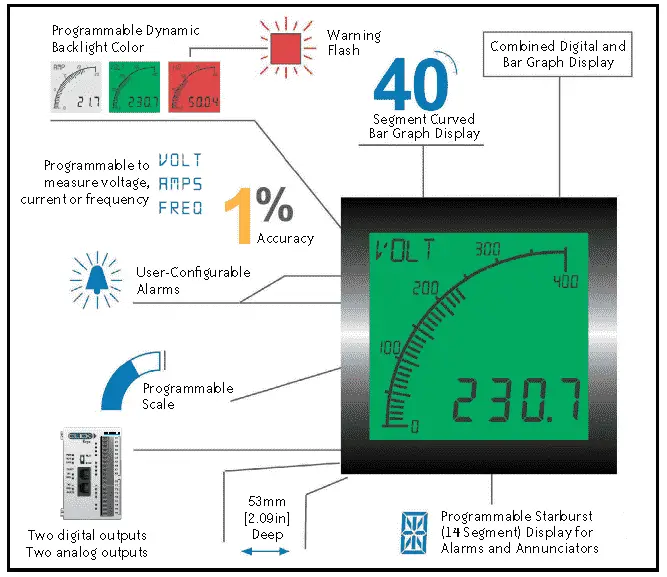

Starting off the year we looked at the Trumeter ADM100 Series Graphical Panel Meter. These units provide the visual representation of an analog meter and the accuracy of a digital meter all in one unit.

The meters feature a programmable bar graph and alarms to immediately alert operators when a parameter is out of range. In addition, a four-character messaging area displays custom messages, alarms, and annunciators.

Trumeter ADM100 Series Graphical Panel Meter

Unboxing the Unit Video

Powering the Unit Video

Installing the Software Video

Configuring the Unit

Click PLC

Automation Direct Click PLC Series

Video Series

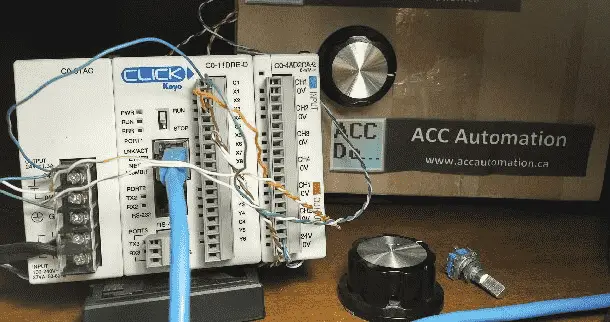

Click PLC HMI Rotary Encoder Dial Input – Video

Rotary encoders are modern digital devices that have taken over from the potentiometer in stereos and many other applications. This is because of their fine digital control and they can fully rotate without end stops. We can connect the rotary encoder into the PLC using just two digital inputs. This human-machine interface (HMI) has the advantage over touch screens and other methods of control into the PLC. The operator can control the rate and setpoint with the dial (rotary encoder) without looking at the control. This will allow the operator to concentration on other tasks.

Click PLC High-Speed Counting Part 1

Click PLC High-Speed Counting Part 2

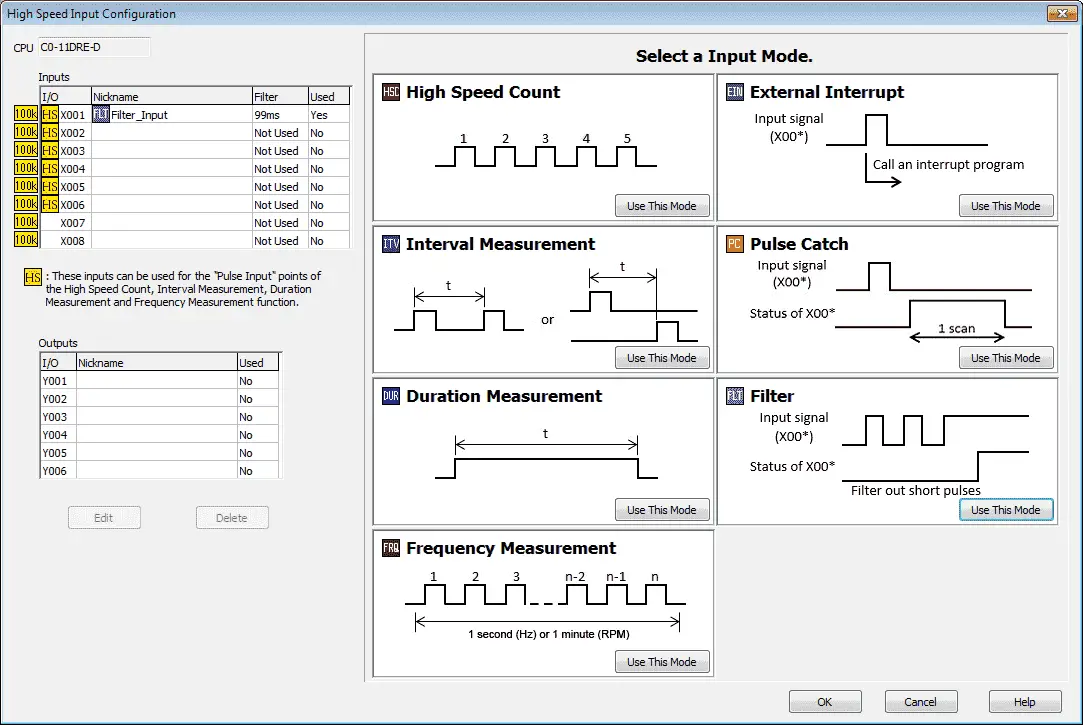

The Click PLC family was updated and now has the ability to use high-speed counting. This is available on all of the Ethernet units that have DC inputs. The faster processor on the Ethernet unit (3 to 10 times faster than the basic unit) allows this capability. There are seven (7) different modes of operation for the high-speed counter available so adaption to your automation solution is easy. The input can count Up, Down, Up/Down, Pulse/Direction or Quadrature (with Z). The maximum speed on the high-speed counter inputs is 100 kHz. That is 100,000 pulses per second.

The Click PLC also introduced a PID instruction.

We created a sample program from scratch to show the math, along with a Factory IO scene to demonstrate PID control using our Click PLC. The PID instruction with autotuning was then used to control the same Factory IO scene.

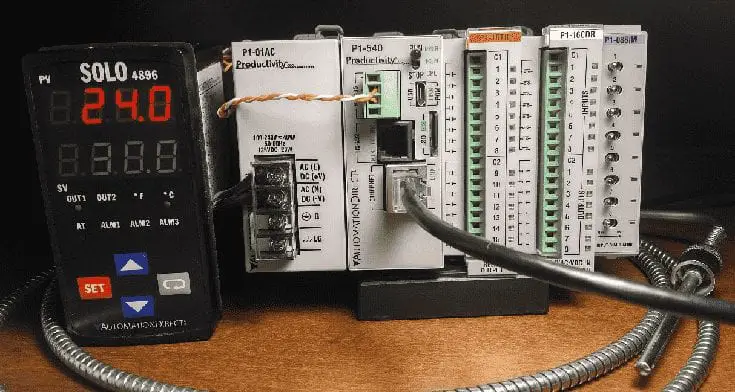

We finished our series on the Productivity 1000 Series PLC :

Productivity 1000 PLC Series – Automation Direct

Video Series Only

The Productivity 1000 series of programmable logic controllers currently has all of these features built into the P1-540 CPU. This CPU (Central Processing Unit) is also known as MPU (Multi-Processing Units) because of the communication capabilities.

– 50MB user memory – Can handle very complex applications easily.

– 4 built-in communication ports – Easy connectivity to your network.

– Data logging up to 32 GB on a microSD card

– Add up to 8 IP modules to communicate to your field sensors. This will give you a total of 128 discrete IO points or 32 analog IO channels.

– Free Software and 30 days of free training with every CPU from Automation Direct.

– Interactive PLC Configuration Tool

– Tag Names

– Auto-discovery IO – Physical I/O tags will be generated based on each module’s position in the base.

– I/O Modules have QR codes under the wiring cover. This can be scanned so you can have the latest specifications/wiring diagrams for the module.

– Limitless PID – Autotuning – Individual or Cascade Mode – etc

– Web Server and Mobile Access

– Advanced Software instruction set

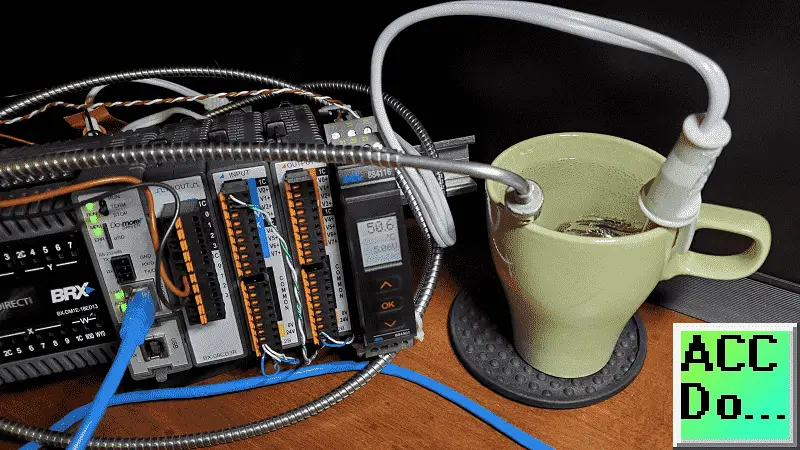

BRX Do-More PLC Additional Posts

One of the features of the BRX Series PLC is the ability to expand its capability to fit your application. Software and hardware changes are ongoing so the PLC can grow with your needs. Communication is something that the BRX PLC can do very well. As part of the internet of things (IoT), the BRX will share and exchange data. You can also refer to this as the industrial internet of things. This will suit several industrial applications.

BRX Do-More PLC Series

Video Series

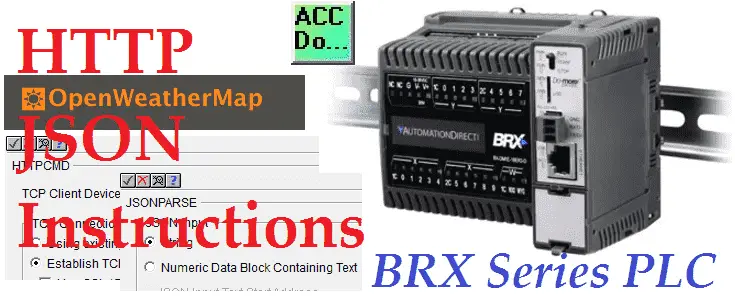

The Do-more Updates Release 2.5.2 on April 22, 2019, included new instructions. Here are the instructions that we used:

BRX PLC HTTP JSON Instructions

HTTPCMD – HTTP Request / Response with Server (BRX only)

JSONPARSE – Parse JSON Text (BRX only)

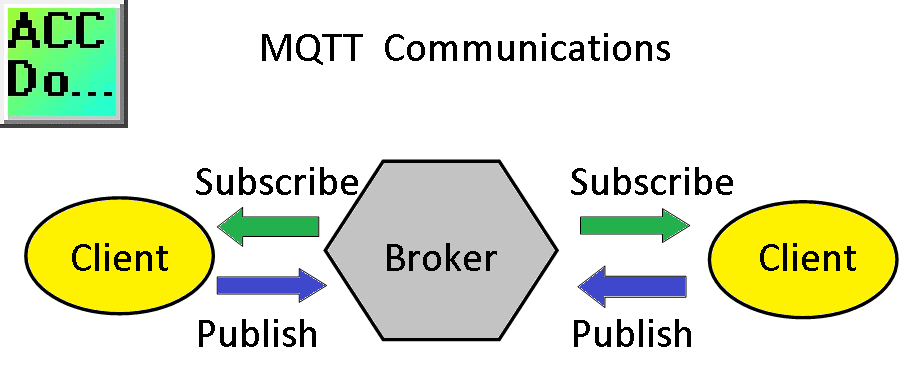

MQTT stands for Message Queuing Telemetry Transport. It is a low resource, simple publish and subscribe communication protocol. This protocol provides machine to machine (M2M) connectivity which is ideal for the Internet of Things (IoT) or Industrial Internet of Things. (IIoT) So far we have used the BRX Simulator and BRX PLC to communicate to an online broker (HQHive) and a private broker (Mosquitto).

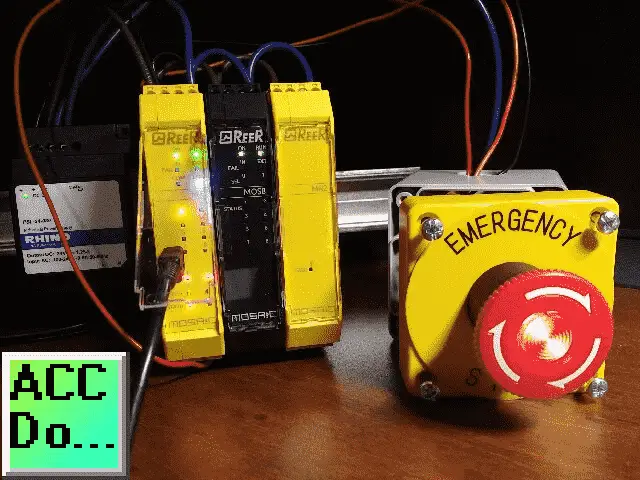

MOSAIC Safety Controller System

Safety controllers monitor over-voltage / short circuit protection, redundant relays, and positive guided contacts to provide a level of fail-safe operation for applications. The modular MOSAIC safety controller is an expandable, cost-effective choice over standalone safety relays. Especially as the required number of relays/channels increases. It will also reduce the wiring of your safety circuits.

Mosaic Modular Safety Integrated Controller

Video Series

ReeR MOSAIC Safety Controller (Automation Direct) Advantages:

– Reduces the number of devices and wiring used and overall size of the project

– Speeding-up control panel construction

– Allows tamper-proof system configurations

– All logic is configured through a graphic interface

– (no more laborious wiring is needed as with traditional solutions)

– The lower number of electromechanical components also means a better performance level and a higher safety level

– The project report provides the actual values of PFH, DCavg, and MTTFd according to EN 13849-1 and EN 62061

C-More EA9 HMI Series Panel

C-More HMI Series Panel

Video Series Only

Human-machine interfaces (HMI) are made to display and control operations for our automation solution. Information is displayed in a graphics format. (Graphical User Interface – GUI) The HMI is usually part of the SCADA (Supervisory Control and Data Acquisition) system.

EA9-T10CL Features:

• Touch screen display (LCD) 280 NITS display brightness

• 10.4” diagonal colour TFT (Thin Film Transistor)

• Analog resistive (1024 X 1024) touch screen allowing unlimited touch areas

• EA9-PGMSW programming software

• 800 x 600-pixel display

• 64K colours

• 50,000-hour average backlight half-life

• USB port B (program/download) and USB port A (USB device options)

• Ethernet 10/100 Base-T port (program/download & PLC communication

• Remote Internet Access

• Serial PLC interface (RS-232/422/485)

• One built-in SD memory card slot

• 12–24 VDC powered (18W), 110VAC power adapter (optional)

• Audio Line Out, stereo – requires amplifier and speaker(s)

• 26MB project memory

• Data logging

• 0 to 50°C [32 to 122°F] operating temperature range

• NEMA 4/4X, IP65 compliant when mounted correctly, indoor use only

• Slim design saves panel space

• UL, cUL & CE agency approvals

• 2-year warranty from date of purchase

Currently, we are in the process of this Automation Direct C-More EA9 HMI Series Panel. We will continue in the New Year with additional communication and special functions of this versatile easy to use HMI panel. We will also continue with looking at the MQTT communication protocol used with the IIoT. (Industrial Internet of Things)

2020 will prove to be an exciting time. Here are some of the items that we have planned.

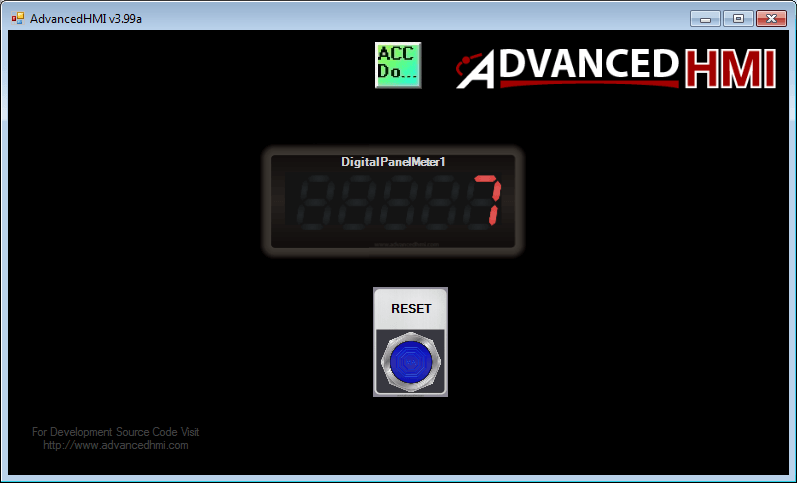

AdvancedHMI – Free VB.Net Human Machine Interface that will run on Visual Studio

We will be using AdvancedHMI to update our series on free robust Data Logging from the PLC.

More examples of Factory IO – 3D simulation of your process

As always we will be answering your questions and applications so you can quickly implement your control solution.

Watch on YouTube:ACC Automation 2019 Review

If you have any questions or need further information please contact me.

Thank you once again for making 2019 the best year yet!

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.