Node-RED Installing the Windows Software

2K views · Oct 12, 2022 accautomation.ca

We will now be installing the Node-RED software on our Windows 10 computer. Node-RED is a powerful and easy programming tool that will allow you to join together hardware devices, APIs (Application Programming Interface), and online services. This joining of information is part of the smart factory. Internet of Things (IoT), Industrial Internet of Things (IIoT), Industry 4.0, and Smart Production are just a few of the other labels that have been applied to this type of technology. Node-RED provides a browser-based flow editor. This provides an easy way to visually see and modifies your program flow. Flows can then be deployed to the runtime in a single click. Node-RED is built on Node.js. This lightweight runtime can be deployed on low-cost hardware (Raspberry Pi ) or cloud services (Microsoft Azure). This has the ability to bring data collection, analysis, and storage closer to the actual device. Real-time edge computing can then be achieved without latency issues. In this series we will be using Node-RED in some of the following ways: - Connect to our industrial equipment using the Modbus protocol. - Display Information on a user interface, HMI, or dashboard - Log information into a database - View information in the database through spreadsheets such as Excel. Let’s get started by installing Node-RED. 00:00 Node-RED Installing the Software 01:58 Running on Windows 02:19 Install Node.js 04:23 Install Node-RED 05:51 Starting and Running Node-RED and Editor 06:44 Working with the Node-RED editor There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://www.accautomation.ca

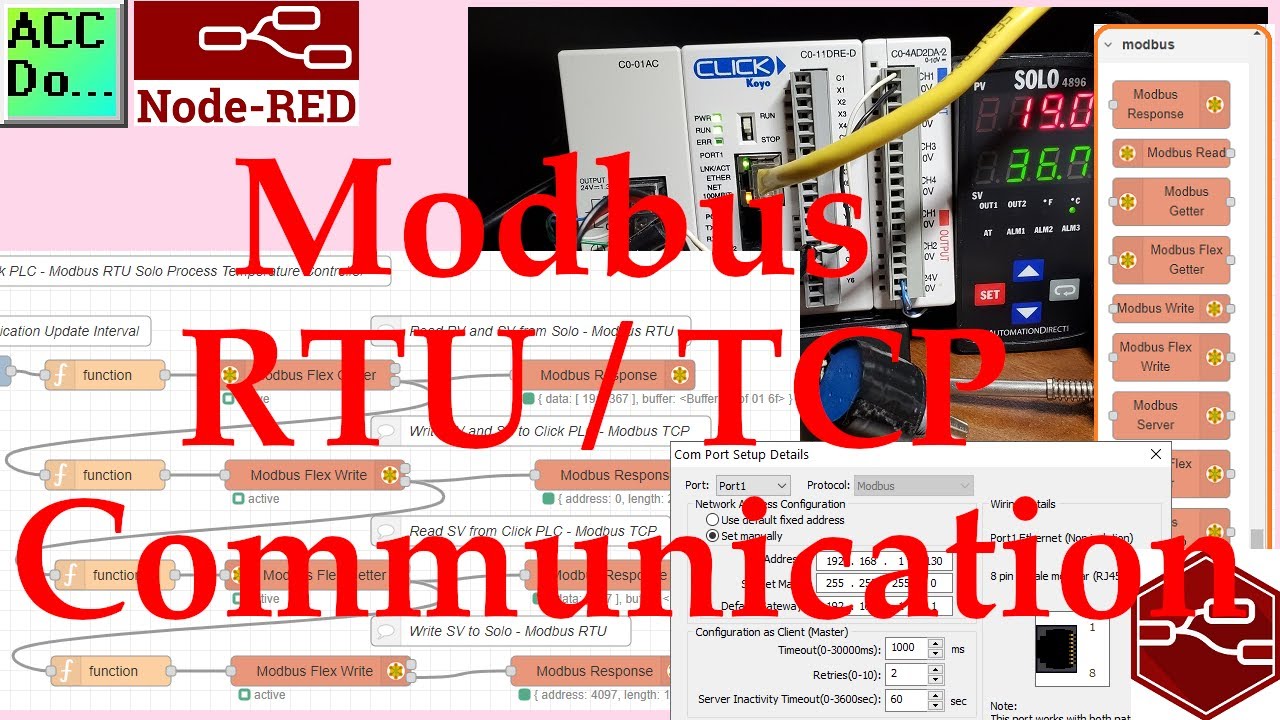

Node-RED Modbus RTU / TCP Communication

5K views · Oct 12, 2022 accautomation.ca

Node-RED can easily connect to industrial controls using Modbus communication. Modbus is a master-slave type of communication. Masters will always send commands to read or write to the slaves on the network. The slaves will respond if the transmission is directed at them. We will be installing the node-red-contrib-Modbus palette. This will allow us to communicate Modbus serial (RS485) RTU to a Solo process temperature controller. We will then use Modbus Ethernet TCP to communicate to a Click PLC. Note: When using Modbus TCP (Ethernet), the master is referred to as the Client, and the slave is a Server. Node-RED will be used to create a single Modbus flow. We will communicate to our Solo process temperature controller using Modbus RTU on a serial RS485 network. The present and set values of the controller will be read. These values will then be written to our Click PLC using an Ethernet Modbus TCP network. A set value from an analog input on the Click will be used to then write to the Solo. This will happen every 200 milliseconds or 5 times per second. Let’s get started using Node-RED for Modbus communication. In this series, we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ Video https://youtu.be/xGzH2Hv31WA We will continue with the following: Connect to our industrial equipment using the Modbus protocol. Additional information can be found on our website at the following URL: https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ Future information will include the following: Display Information on a user interface, HMI, or dashboard Log information into a database View information in the database through spreadsheets such as Excel. 00:00 Node-RED Modbus Click PLC and Solo Process Temperature Controller 02:06 Installing node-red-contrib-modbus Palette 04:05 Node-RED Modbus Flow Program 09:06 Solo Process Temperature Controller - Modbus RTU 09:45 USB to RS485 Converter Settings 10:34 Hardware Click PLC, Solo, USB to RS485 Converter 12:15 Click PLC Modbus TCP Settings 14:30 Click PLC Modbus Addresses 15:03 Node-RED Modbus RTU TCP Flow Program Example There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. ACC Automation https://accautomation.ca/

Node-RED User Interface - Dashboards

9K views · Oct 12, 2022 accautomation.ca

Node-RED can easily display interactive information to the user or operator using a web browser on your phone, tablet, or computer. Any device that has access to the network in which node-red is running. We will be installing the node-red-dashboard palette. This allows us to create a live data dashboard user interface. (UI) The information from our Solo process temperature controller will be displayed. Setpoint information can be set either by the dashboard UI or the Click analog input signal. This will be selected via the user interface. Let’s get started using Node-RED Dashboards. In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc Additional links and information in the video can be obtained from our website post: https://accautomation.ca/node-red-user-interface-dashboards/ We will continue with the following: Display Information on a user interface, HMI, or dashboard Log information into a database View information in the database through spreadsheets such as Excel. 00:00 Node-RED User Interface - Dashboards 01:32 Install node-red dashboard 02:35 Node-red dashboard program addition 10:15 Node-red hardware 12:11 Running node-red program There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://www.accautomation.ca

Node-RED User Interface - Dashboards

18K views · Oct 12, 2022 accautomation.ca

Node-RED can easily display interactive information to the user or operator using a web browser on your phone, tablet, or computer. Any device that has access to the network in which node-red is running. We will be installing the node-red-dashboard palette. This allows us to create a live data dashboard user interface. (UI) The information from our Solo process temperature controller will be displayed. Setpoint information can be set either by the dashboard UI or the Click analog input signal. This will be selected via the user interface. Let’s get started using Node-RED Dashboards. In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc Additional links and information in the video can be obtained from our website post: https://accautomation.ca/node-red-user-interface-dashboards/ We will continue with the following: Display Information on a user interface, HMI, or dashboard Log information into a database View information in the database through spreadsheets such as Excel. 00:00 Node-RED User Interface - Dashboards 01:32 Install node-red dashboard 02:35 Node-red dashboard program addition 10:15 Node-red hardware 12:11 Running node-red program There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://www.accautomation.ca

Node-RED SQL Database Log - Modbus Logging

8K views · Oct 12, 2022 accautomation.ca

Node-RED can easily log data to a database. SQL (Structured Query Language) can be used to communicate to a SQL database. Databases separate analysis from the data unlike spreadsheets like Excel. The database is designed to hold more information than spreadsheets and allow multiple users to access the information. We will be creating an SQLite SQL database. SQLite Studio will be used to design the structure of the database. (Tables) Installing the node-red-sqlite-node palette will allow us to log the information from our Solo process temperature controller, Click PLC, and dashboard variables. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/node-red-sql-database-log-modbus-logging/ In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc We will continue with the following: Log information into a database View information in the database through spreadsheets such as Excel. 00:00 Node-RED SQL Database Log 01:28 Download/Install SQLite 02:32 Download/Install SQLite Studio 03:22 SQLite Studio Create Database 08:53 Node-RED SQLite Install 09:54 Node-RED SQL Database Log Program 12:04 Node-RED Database Program Run There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://www.accautomation.ca

Node-RED SQL Database Spreadsheet Connection

5K views · Oct 12, 2022 accautomation.ca

We will now look at the connection to our SQL database using a spreadsheet application. Previously we used Node-RED to communicate Modbus TCP and RTU to our Click PLC and Solo Temperature Controller. The information collected from the controllers was then put into an SQLite SQL database. Spreadsheets like Excel are great for analysis of the data. We will be connecting to our SQLite SQL database with WPS spreadsheets. This will be accomplished by using an ODBC driver as the translator between the database and spreadsheet. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo We will continue with the following: View information in the database through spreadsheets such as Excel. 00:00 Node-RED SQL Database Spreadsheet Connection 03:00 What is ODBC? 03:26 SQLite ODBC Driver Install 04:39 SQLite ODBC Driver Settings 06:18 WPS Office Spreadsheets 06:45 WPS Office Spreadsheets Import Data There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://accautomation.ca/

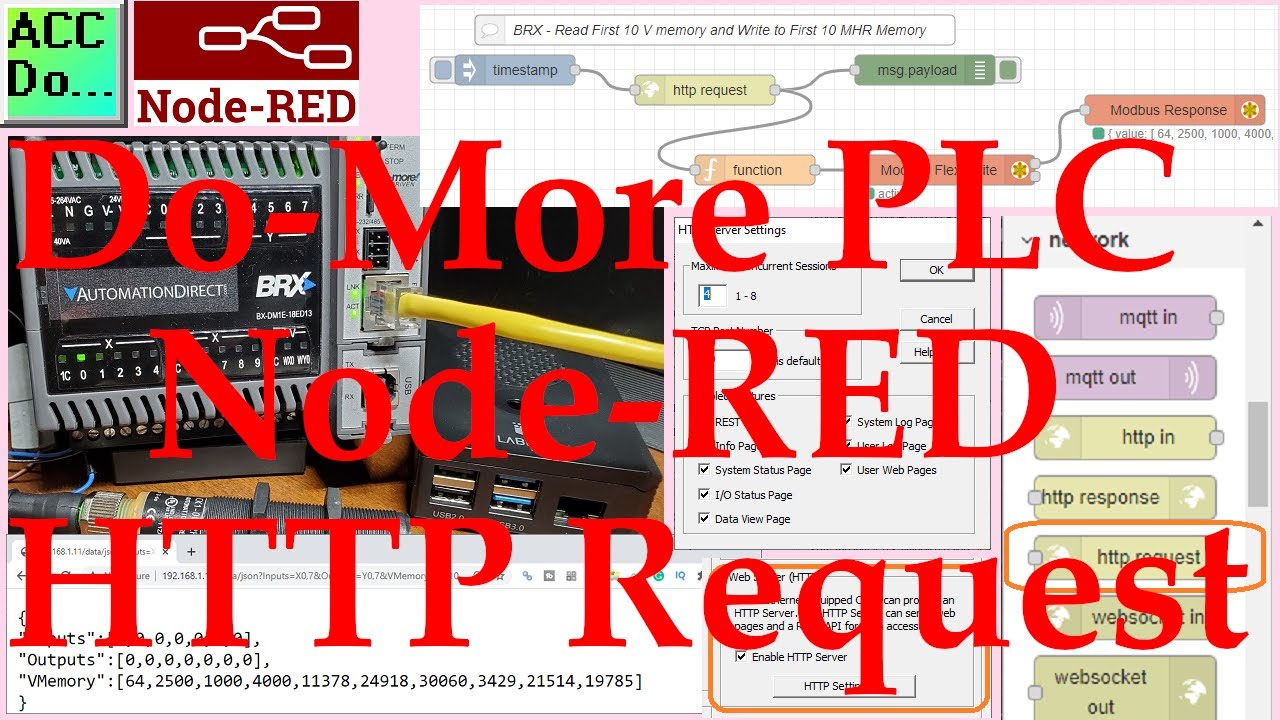

Do-More PLC Node-RED HTTP Request

448 views · Oct 12, 2022 accautomation.ca

Node-RED HTTP Request can be used to read any BRX Do-More PLC memory area. This HTTP (Hypertext Transfer Protocol) communication will only read information from our controller. The BRX Do-More REST API is used to read information using a URL (Uniform Resource Locator) or web address. We will be using the HTTP request node in Node-RED to read information from our BRX Do-More REST API-enabled controller. Writing using Modbus will also be shown. This will all be done on our Raspberry Pi 4 single-board computer. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/do-more-plc-node-red-http-request/ In this series we started using Node-RED in some of the following ways: The entire series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI Install Node-RED on Raspberry Pi 4 https://accautomation.ca/install-node-red-on-raspberry-pi-4/ https://youtu.be/KleNtxvJkU4 Simple Click Data Logging https://accautomation.ca/simple-click-data-logging-node-red/ https://youtu.be/RmSn4ZSPSmg We will continue with the following: Do-More PLC Node-RED HTTP Request 00:00 Do-More PLC Node-RED HTTP Request 01:12 Do-More REST API Setup 02:20 Do-More Ethernet Security 03:15 Do-More Static IP Address 04:04 Do-More Modbus TCP Server Configuration 04:40 Testing the REST API and Hardware 07:10 Node-Red HTTP Request 10:57 Node-RED Read Write Do-More PLC There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://accautomation.ca/

Install Node-RED on Raspberry Pi

27K views · Oct 12, 2022 accautomation.ca

We will now be installing Node-RED on a Raspberry Pi 4 single-board computer. A static IP address will also be given for both the WiFi and Ethernet connections. The Raspberry Pi has quickly become a fixture in the industrial environment when utilizing the internet of things. (IoT) We will be utilizing this low-cost computer to poll and log information from our PLCs using Modbus and MQTT protocols. Node-RED will be the IoT enabling software that will allow us to utilize this hardware. https://accautomation.ca/series/node-red-iot-enabling-software/ Let’s get started with installing Node-RED and setting up a fixed IP address on our Raspberry Pi 4 computer. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/install-node-red-on-raspberry-pi-4/ In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI We will continue with the following: Installing Node-RED on a Raspberry Pi 4 single-board computer 00:00 Install Node-RED on Raspberry Pi 00:30 Raspberry Pi update operating system (OS) 01:37 Node-RED Raspberry Pi script to install or update 03:43 Raspberry Pi Static IP Address 04:09 MAC address 04:50 DHCP client daemon (DHCPCD) 06:50 Auto start Node-RED service 07:44 Hardware and starting the Node-RED editor There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. ACC Automation https://accautomation.ca/

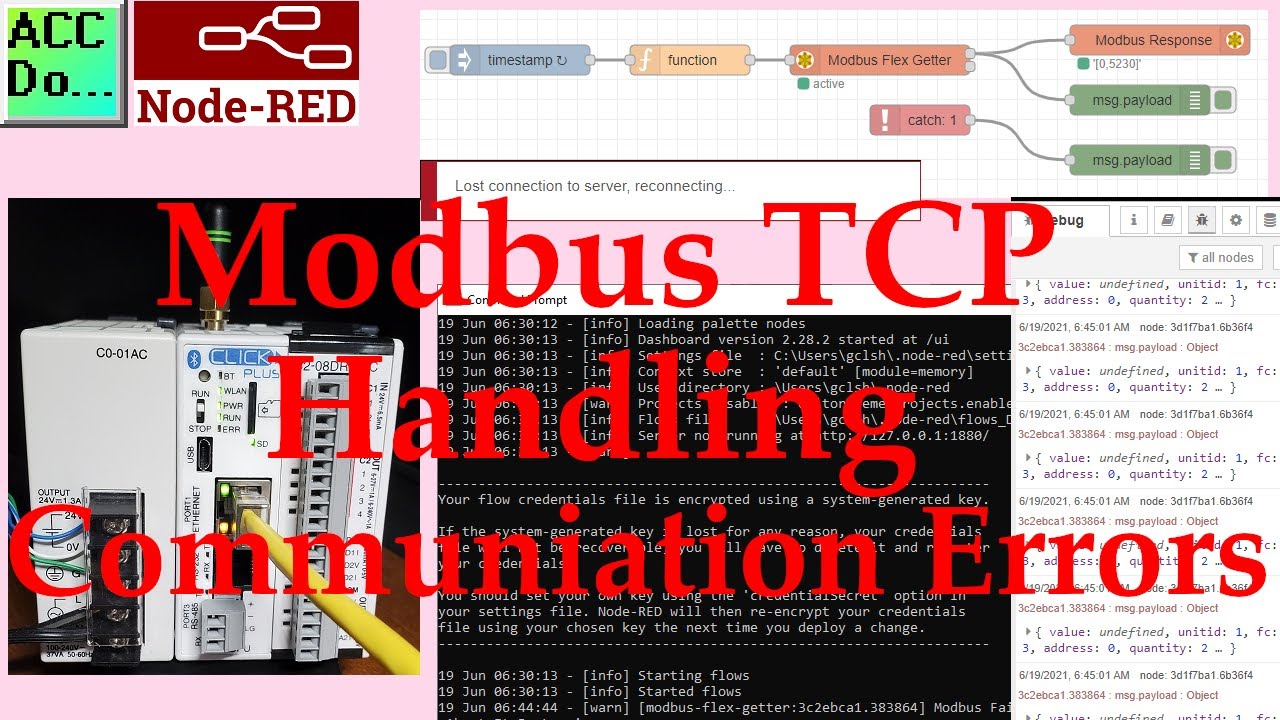

Node-RED Modbus TCP Handling Communication Errors

3K views · Oct 12, 2022 accautomation.ca

Node-RED Modbus TCP can recover from communication errors automatically. Options are available to you the programmer to continue the Node-RED flow upon detection of these errors. Broken Ethernet cable, Modbus Server power, and Node-RED Client offline are just a few of the errors that can occur on the industrial plant floor. Our Node-RED program must account for and be tested for each of these conditions. We will be communicating Modbus TCP (Ethernet) to our Click Plus PLC. Using the catch node we will detect and display errors that may occur. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/node-red-modbus-tcp-handling-errors/ In this series we started using Node-RED in some of the following ways: The entire series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI Install Node-RED on Raspberry Pi 4 https://accautomation.ca/install-node-red-on-raspberry-pi-4/ https://youtu.be/KleNtxvJkU4 Do-More PLC Node-RED HTTP Request https://accautomation.ca/do-more-plc-node-red-http-request/ https://youtu.be/m-p28H9Fl5s Simple Click Data Logging https://accautomation.ca/simple-click-data-logging-node-red/ https://youtu.be/RmSn4ZSPSmg We will continue with the following: Node-RED Modbus TCP Handling Errors 00:00 Node-RED Modbus TCP Handling Errors 00:01 Node-RED Windows Startup 00:02 Node-RED Modbus TCP Communication Program 00:03 Click Plus Modbus TCP Server Program 00:04 Node-RED Modbus TCP Testing Errors There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://accautomation.ca/

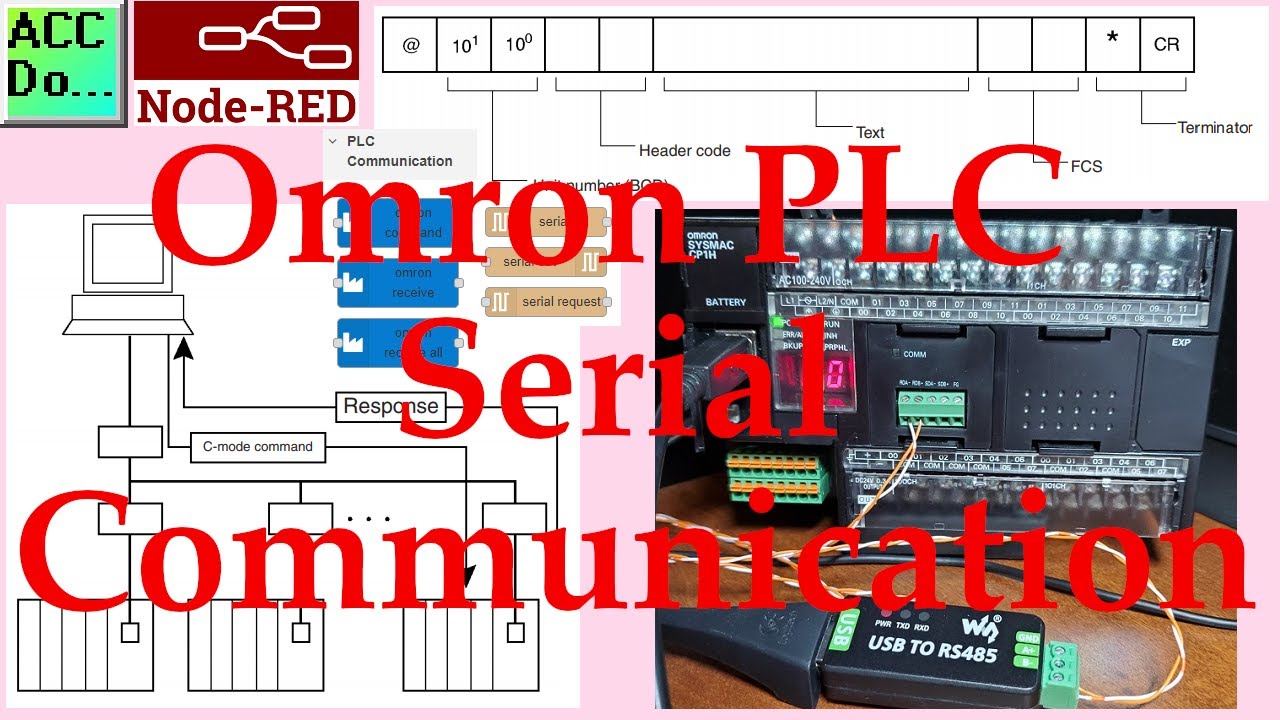

Omron PLC Node-RED Serial Communication

25K views · Oct 12, 2022 accautomation.ca

PLC manufacturers have their own proprietary protocols. These methods of communication will allow you to program the controller. Other protocols will allow you to collect and log information from the programmable logic controller. Node-RED can read and write to the Omron controller using special protocol commands. We will connect Node-RED to the Omron CP1H PLC. A serial RS485 interface will be used for communication with the industrial controller. We will demonstrate reading and writing using Host Link (C-mode commands) to the Omron PLC. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-plc-node-red-serial-communication/ Purchase your USB to RS-485 serial adapter from the following affiliate link. https://amzn.to/35UNc6v In this series, we started using Node-RED in some of the following ways: The entire series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI Install Node-RED on Raspberry Pi 4 https://accautomation.ca/install-node-red-on-raspberry-pi-4/ https://youtu.be/KleNtxvJkU4 Do-More PLC Node-RED HTTP Request https://accautomation.ca/do-more-plc-node-red-http-request/ https://youtu.be/m-p28H9Fl5s Simple Click Data Logging https://accautomation.ca/simple-click-data-logging-node-red/ https://youtu.be/RmSn4ZSPSmg Node-RED Modbus TCP Handling Errors https://accautomation.ca/node-red-modbus-tcp-handling-errors/ https://youtu.be/CgsJozTr-8w Raspberry Pi Serial Port Programming https://accautomation.ca/raspberry-pi-serial-port-programming/ https://youtu.be/SAY8H3SBl-8 We will continue with the following: Omron PLC Node-RED Serial Communication 00:00 Omron PLC Node-RED Serial Communication 01:09 Omron C-mode (Host Link) 02:17 Omron C-mode (Host Link) Command/Response Formats 03:46 Omron C-mode (Host Link) Command Codes 05:02 CP1W-CIF11 RS-422A/485 Option Boards 06:16 Waveshare USB to RS485 Converter 06:40 Omron CP1H Program and Settings 09:12 Node-RED Program Nodes Required 10:23 Node-RED Omron Serial Read Flow 14:54 Omron Hardware and USB to RS485 Converter 16:07 Executing the Node-RED Flow to Read from the Omron 18:05 Node-RED Omron Serial Write Flow 19:48 Executing the Node-RED Flow to Write to the Omron There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://accautomation.ca/

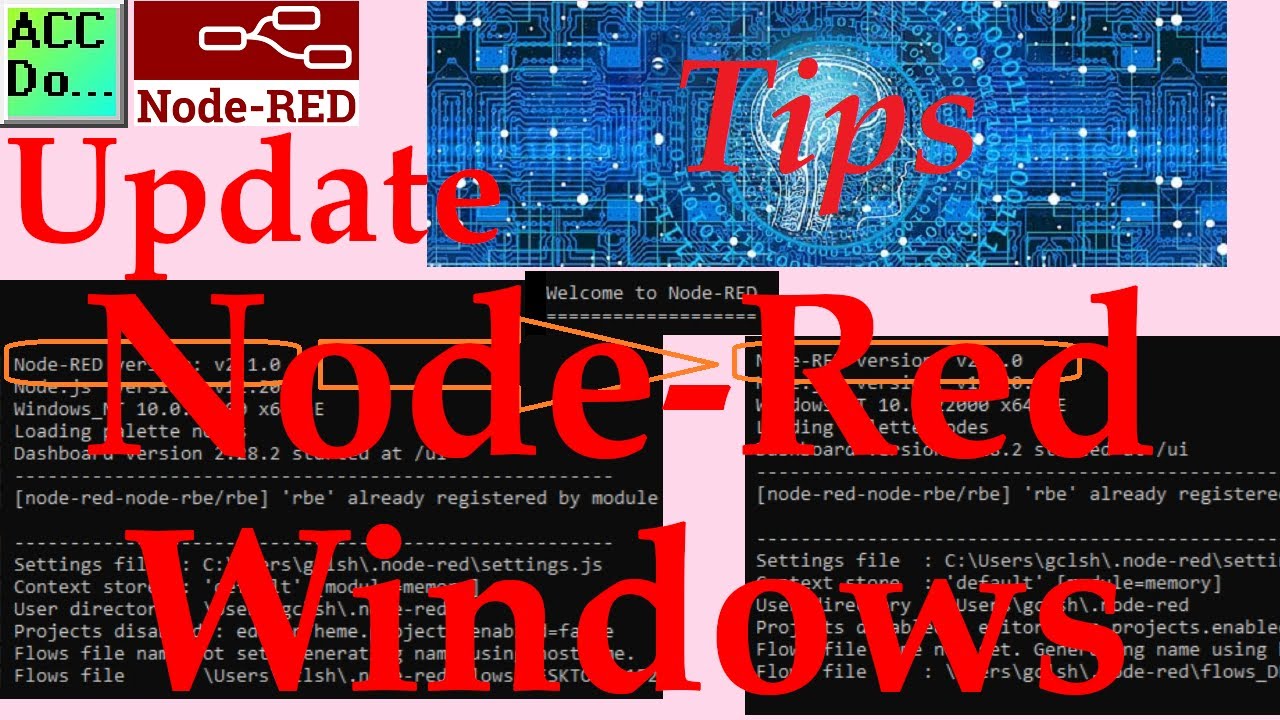

Update Node-Red on Windows

81 views · Oct 11, 2022 accautomation.ca

Update Node-Red on Windows Call up a command prompt. Start CMD on windows. Type node-red at the prompt to start the software. You will see the current version under the "Welcome to Node-Red" heading. This version is v2.1.0. Ctrl + C will stop the running of Node-Red. Type "npm install -g --unsafe-perm node-red". This will start the update or installation of Node-Red. Once the software has been updated, type node-red again at the prompt. This will start our software. Our new version v2.2.0 will now be displayed. Our Node-RED Series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ This will take you through installing, communicating to the PLC, HMI (dashboards), saving to a SQL database, and analyzing the data with spreadsheets. There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. #shorts ACC Automation https://accautomation.ca/

Node RED Install MQTT Broker AEDES

341 views · Oct 9, 2022 accautomation.ca

Node-RED Install MQTT Broker AEDES You can use the MQTT protocol in Node-RED without an external MQTT broker like Mosquitto. Select manage palette (AlT + Shift + P) from the main menu. Select the install tab. Type AEDES in the search. The node-red-contrib-aedes will be displayed. Select the install button on the right-hand side. Your MQTT broker will now be installed. The Aedes broker node will be under the network on the left-hand side. Simply click and drag it onto your workspace. Here is a comparison of MQTT brokers: https://github.com/mqtt/mqtt.org/wiki/server-support Our Node-RED Series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ This will involve installing, communicating to the PLC, HMI (dashboards), saving to a SQL database, and analyzing the data with spreadsheets. There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, etc. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases Easily make industrial solutions for the Internet of Things (IoT, IIoT). Node-RED provides the ability for you to quickly create custom control solutions. #shorts ACC Automation https://accautomation.ca/

Install Node-RED on Raspberry Pi

6K views · Sep 9, 2022 accautomation.ca

We will now be installing Node-RED on a Raspberry Pi 4 single-board computer. A static IP address will also be given for both the WiFi and Ethernet connections. The Raspberry Pi has quickly become a fixture in the industrial environment when utilizing the internet of things. (IoT) We will be utilizing this low-cost computer to poll and log information from our PLCs using Modbus and MQTT protocols. Node-RED will be the IoT enabling software that will allow us to utilize this hardware. https://accautomation.ca/series/node-red-iot-enabling-software/ Let’s get started with installing Node-RED and setting up a fixed IP address on our Raspberry Pi 4 computer. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/install-node-red-on-raspberry-pi-4/ In this series we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI We will continue with the following: Installing Node-RED on a Raspberry Pi 4 single-board computer 00:00 Install Node-RED on Raspberry Pi 00:30 Raspberry Pi update operating system (OS) 01:37 Node-RED Raspberry Pi script to install or update 03:43 Raspberry Pi Static IP Address 04:09 MAC address 04:50 DHCP client daemon (DHCPCD) 06:50 Auto start Node-RED service 07:44 Hardware and starting the Node-RED editor There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. ACC Automation https://accautomation.ca/

Node-RED Modbus RTU / TCP Communication

7K views · Sep 9, 2022 accautomation.ca

Node-RED can easily connect to industrial controls using Modbus communication. Modbus is a master-slave type of communication. Masters will always send commands to read or write to the slaves on the network. The slaves will respond if the transmission is directed at them. We will be installing the node-red-contrib-Modbus palette. This will allow us to communicate Modbus serial (RS485) RTU to a Solo process temperature controller. We will then use Modbus Ethernet TCP to communicate to a Click PLC. Note: When using Modbus TCP (Ethernet), the master is referred to as the Client, and the slave is a Server. Node-RED will be used to create a single Modbus flow. We will communicate to our Solo process temperature controller using Modbus RTU on a serial RS485 network. The present and set values of the controller will be read. These values will then be written to our Click PLC using an Ethernet Modbus TCP network. A set value from an analog input on the Click will be used to then write to the Solo. This will happen every 200 milliseconds or 5 times per second. Let’s get started using Node-RED for Modbus communication. In this series, we started using Node-RED in some of the following ways: Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ Video https://youtu.be/xGzH2Hv31WA We will continue with the following: Connect to our industrial equipment using the Modbus protocol. Additional information can be found on our website at the following URL: https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ Future information will include the following: Display Information on a user interface, HMI, or dashboard Log information into a database View information in the database through spreadsheets such as Excel. 00:00 Node-RED Modbus Click PLC and Solo Process Temperature Controller 02:06 Installing node-red-contrib-modbus Palette 04:05 Node-RED Modbus Flow Program 09:06 Solo Process Temperature Controller - Modbus RTU 09:45 USB to RS485 Converter Settings 10:34 Hardware Click PLC, Solo, USB to RS485 Converter 12:15 Click PLC Modbus TCP Settings 14:30 Click PLC Modbus Addresses 15:03 Node-RED Modbus RTU TCP Flow Program Example There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. ACC Automation https://accautomation.ca/

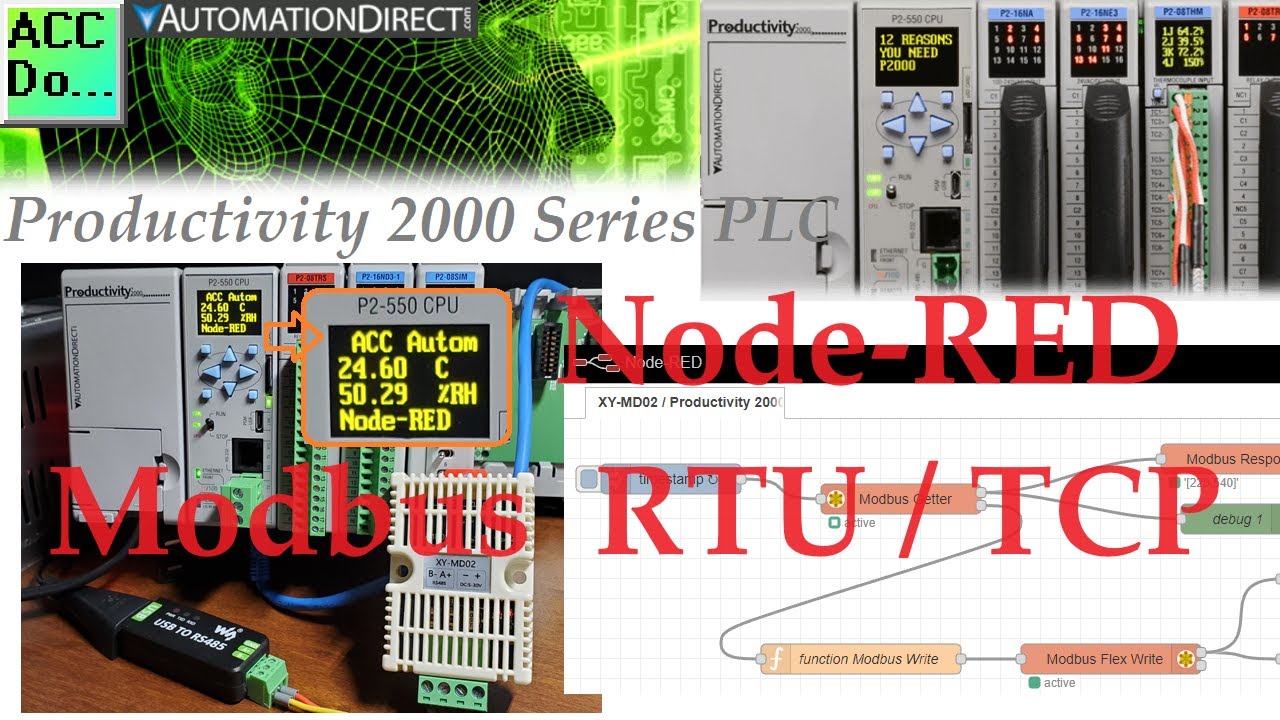

Productivity 2000 PLC Node-RED Modbus TCP

10K views · Nov 13, 2023 accautomation.ca

We will now look at communication between the Productivity 2000 PLC (Modbus TCP Server) and Node-RED (Modbus TCP Client). Node-RED is a powerful, adaptable HMI/SCADA (Supervisory Control and Data Acquisition) development package that uses flow programming. Minimal coding is required; you can see the program flow visually. The best thing is that the software is free. We will look at using Node-RED with the Productivity 2000 Series PLC. Node-RED will be used to create a single Modbus flow. We will communicate to our XY-MD02 Temperature and Humidity sensor using Modbus RTU on a serial RS485 network. The present values of the sensor will be read. These values will then be written to our Productivity 2000 PLC using an Ethernet Modbus TCP network. These temperature and humidity readings will then be displayed on the P2000 CPU. Let's get started using Node-RED for Modbus communication. Detailed information can be found on our website. The post for this video is located here: https://accautomation.ca/productivity-2000-plc-node-red-modbus-tcp/ 00:00 Productivity 2000 PLC Node-RED Modbus TCP 01:31 Installing or Updating Node-RED 04:42 Node-RED Modbus Nodes 06:26 XY-MD02 Temperature and Humidity Sensor 07:35 P2000 Modbus Server Program 09:22 Node-RED Flow Program The Productivity 2000 Series PLC is located here: https://accautomation.ca/series/productivity-2000-series-plc-p2000/ Previously in this Productivity 2000 series PLC, we have discussed some of the following: P2000 Hardware Features https://accautomation.ca/productivity-2000-series-plc-p2000-hardware/ https://youtu.be/83MfQK7fzdk Productivity Suite Programming Software Install https://accautomation.ca/productivity-2000-series-plc-software-install/ https://youtu.be/4MTOIrWA1L8 Productivity 2000 Series PLC Communication https://accautomation.ca/productivity-2000-series-plc-communication/ https://youtu.be/UoHoMwk-zi0 First Program https://accautomation.ca/productivity-2000-series-plc-first-program/ https://youtu.be/RLwPofIkIxA PLC Debug Mode https://accautomation.ca/productivity-2000-series-plc-debug-mode/ https://youtu.be/cHtrMaQIS-c PLC Program Documentation https://accautomation.ca/productivity-2000-series-plc-program-documentation/ https://youtu.be/OiZKZnjyMew PLC CPU Display https://accautomation.ca/productivity-2000-series-plc-cpu-display/ https://youtu.be/OWEK2p7NbuE PLC Tag Database https://accautomation.ca/productivity-2000-series-plc-tag-database/ https://youtu.be/rontLQnSSsE Ladder Logic Math https://accautomation.ca/productivity-2000-plc-ladder-logic-math/ https://youtu.be/HZdITEWGSm8 Data Logger and Logging https://accautomation.ca/productivity-2000-plc-data-logger-and-logging/ https://youtu.be/lCW0gQ0SKjI P2000 PLC Web Server (HTTP) https://accautomation.ca/productivity-2000-plc-web-server-http/ https://youtu.be/qSo28Csye9Y P2000 Series PLC Modbus RTU Serial Communication https://accautomation.ca/productivity-2000-series-plc-modbus-rtu-serial/ https://youtu.be/2SuIiLKrwqk P2000 Series PLC Modbus TCP Ethernet https://accautomation.ca/productivity-2000-series-plc-modbus-tcp-ethernet/ https://youtu.be/F6cqbNZ5M4I There are several reasons why we are using the Productivity 2000 Series Controller. Here are just a few. - CPU with five communication ports - 50MB user memory - Can handle very complex applications easily. - Limitless PID – Autotuning – Individual or Cascade Mode - etc - OLED message display on the CPU module - Plenty of discrete and analog I/O modules - Status displays on all discrete I/O modules - I/O Modules have QR codes. This can be scanned to have the latest specifications/wiring diagrams for the module. - OLED data display on analog modules - P2-RS remote I/O expansion module, or use the Productivity1000 P1-RX remote expansion module to add even lower-cost remote I/O to your system - FREE full-featured Productivity Suite software - Programming with several ports - USB, Ethernet, Serial - Hardware auto-discovery - Hot-swappable I/O - Remove cards with power on the system - Choose from three wiring options - Slim DIN rail density form factor: - hardware - power supply, CPU, and seven modules in only 10-1/2 inches - All project files (program, tag name database, and all the program documentation) in the CPU - Run-time editing and debug mode on CPU - Easy data logging with micro SD on CPU - Secure Web server to access data files and system tags - Easy drive and motion controller integration - Coordinate motion control with PS-AMC allows control of up to 16 axes and synchronization of up to 4 axes - Two-Year Warranty The Productivity 2000 series of programmable logic controllers currently has all of these features built into the P2-550 CPU. This CPU (Central Processing Unit) is also known as PAC (Programmable Automation Controller) because of its communication capabilities. ACC Automation https://www.accautomation.ca

Node RED: Empower Your Creativity in IoT and Automation!

2K views · Jan 9, 2025 accautomation.ca

Learn about Node-RED, a flow-based programming tool for connecting devices, services, and APIs. Discover its features, IoT and process automation applications, and how it simplifies complex workflows for beginners and experienced developers. Connect to our industrial equipment using the Modbus protocol. Additional information can be found on our website at the following URL: https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ The entire Node-RED series can be found here: https://accautomation.ca/series/node-red-iot-enabling-software/ There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides you with the ability to quickly create custom control solutions. ACC Automation https://accautomation.ca/

Node RED: Empower Your Creativity in IoT and Automation!

2K views · Jan 9, 2025 accautomation.ca

Learn about Node-RED, a flow-based programming tool for connecting devices, services, and APIs. Discover its features, IoT and process automation applications, and how it simplifies complex workflows for beginners and experienced developers. Connect to our industrial equipment using the Modbus protocol. Additional information can be found on our website at the following URL: https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ The entire Node-RED series can be found here: https://accautomation.ca/series/node-red-iot-enabling-software/ There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides you with the ability to quickly create custom control solutions. ACC Automation https://accautomation.ca/

Unlock Your Creativity with the Click PLUS PLC C2-NRED - The...

2K views · Mar 3, 2025 accautomation.ca

CLICK PLUS and Node-RED® The most affordable and user-friendly PLC in the industry, with one of the most popular open-source software tools in the industrial sector for developing IIoT applications. What a combination... Automation Directs features: https://www.automationdirect.com/clickplcs/clickplus/intelligent-modules?_gl=1*1x0hsrt*_up*MQ..*_gs*MQ..&gclid=CjwKCAiAlPu9BhAjEiwA5NDSA5G_vXqLE2Etykp5rmAwcQ9iJcgFFhW6JVW05i1_Wd_2UplyCOS_ohoCPhUQAvD_BwE#nodered ACC Automation Click PLC Series: https://accautomation.ca/series/click-plc/ ACC Automation Node-RED Series: https://accautomation.ca/series/node-red-iot-enabling-software/

CLICK PLUS C2-NRED: Easy Install for PLC Module!

499 views · Mar 10, 2025 accautomation.ca

Click PLC and Node RED combine to make a powerful automation system. This step-by-step guide teaches installing a PLC C2-NRED module in the CLICK PLUS option slot. We will cover the basics of PLC module installation, making it perfect for beginners or those new to the CLICK PLUS series. Get ready to upgrade your automation system with ease! Node-RED is a visual programming tool for connecting physical hardware devices, APIs, and online services as part of the Internet of Things. Node-RED's drag-and-drop interface makes it easy to create complex flows with minimal code. Whether you're an industrial automation professional or a DIY enthusiast, we will walk you through installing the Node-RED PLC module in the CLICK PLUS option slot. From preparation to installation, we've got you covered. Let's start now and take your automation skills to the next level! More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ 00:00 CLICK PLUS C2-NRED: Easy Install for PLC Module! 01:15 What are Node-RED and the Click C2-NRED Module? 02:11 Download and Install Click PLC Programming Software Version 3.70 05:00 Update the Click PLUS PLC Firmware 08:00 Install the C2-NRED Click PLUS Slot Module 08:50 Update the C2-NRED Module Firmware 12:41 Configuring the C2-NRED Module 13:55 Programming the Click PLUS PLC C2-NRED Module Previously, we looked at some of the following: Click Plus Software Installation https://accautomation.ca/click-plus-software-installation-version-3-00/ https://youtu.be/6uQQzyZ-O3s Establish Communication https://accautomation.ca/click-plus-establish-communication/ https://youtu.be/1Bnx3IROCqk MQTT Communication https://accautomation.ca/click-plus-plc-mqtt-communication/ https://youtu.be/wzUBolN9KjQ Data Logging https://accautomation.ca/click-plus-data-logging-csv-file-sql-database/ https://youtu.be/ydoWvMzHSKc Click Plus Real Time Clock https://accautomation.ca/click-plus-real-time-clock-setup-and-use/ https://youtu.be/0Vlqo8p0vCI Click PLC Serial Communication Timing https://accautomation.ca/click-plc-serial-communication-timing/ https://youtu.be/wbG_BKcdU1k Retentive Data Memory Registers https://accautomation.ca/click-plc-retentive-data-memory-registers/ https://youtu.be/9sCfu10xyu0 Click PLC Analog Input Non-Linear Scaling https://accautomation.ca/click-plc-analog-input-non-linear-scaling/ https://youtu.be/aRaugN3DYfs How to Connect Pushbutton Switch to Programmable Controller https://accautomation.ca/how-to-connect-pushbutton-switch-to-plc/ https://youtu.be/dSctVgxelZI Click on the Remote PLC Mobile App https://accautomation.ca/click-remote-plc-mobile-application/ https://youtu.be/vhfcsu_bjdc Mastering Click PLC Communication Modbus RS485! https://accautomation.ca/mastering-click-plc-communication-modbus-rs485/ https://youtu.be/RQ4ik2UoRns CLICK PLCs were designed with simplicity in mind, providing reliable control at a low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications, or anywhere a simple system needs a budget-saving control solution. Building on the original CLICCLICK'sple design, the new CLICK PLUS PLCs offer the same practical control but with surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) include the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

Unleash Innovation: Node-RED Flow in Click PLC

662 views · Mar 17, 2025 accautomation.ca

Creating a Node-RED Flow Program in the Click PLUS PLC C2-NRED Module Node-RED is an innovative and powerful tool for connecting hardware devices, APIs, and online services. Regarding industrial automation, the Click PLUS PLC C2-NRED module takes things up a notch by integrating Node-RED, allowing users to create flows via a visual programming interface. Previously, we updated the Click Programming Software to version 3.70. The firmware in the Click CPU and C2-NRED Module were then updated to their latest versions. We will guide you through creating your first Node-RED flow program in the Click PLUS PLC C2-NRED module. We will read and write information to and from the Click PLC CPU. We will discuss saving and retrieving our flow programs and troubleshooting. Let's get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ 00:00 Unleash Innovation: Node-RED Flow in Click PLC 01:11 Accessing Node-RED 02:23 What is Flow Programming? 03:29 Understanding the Node-RED Interface 05:09 Building Your First CLICK Read Flow 07:54 Adding A CLICK Write To Our Flow 11:39 Configure The Inject Node 12:22 Saving The Node-RED Flow - Export / Import Previously, we looked at the following: Data Logging https://accautomation.ca/click-plus-data-logging-csv-file-sql-database/ https://youtu.be/ydoWvMzHSKc Click Plus Real Time Clock https://accautomation.ca/click-plus-real-time-clock-setup-and-use/ https://youtu.be/0Vlqo8p0vCI Click PLC Serial Communication Timing https://accautomation.ca/click-plc-serial-communication-timing/ https://youtu.be/wbG_BKcdU1k Retentive Data Memory Registers https://accautomation.ca/click-plc-retentive-data-memory-registers/ https://youtu.be/9sCfu10xyu0 Click PLC Analog Input Non-Linear Scaling https://accautomation.ca/click-plc-analog-input-non-linear-scaling/ https://youtu.be/aRaugN3DYfs How to Connect Pushbutton Switch to Programmable Controller https://accautomation.ca/how-to-connect-pushbutton-switch-to-plc/ https://youtu.be/dSctVgxelZI Click to Click PLC Communication https://accautomation.ca/click-to-click-plc-communication-remote-io/ https://youtu.be/fMg1mz19-B0 Click PLC to Click PLC Communication RS485 https://youtu.be/EySxKZjm6uE Click PLC to Click PLC Communication Ethernet https://youtu.be/zLvJKxUrjww Click PLC to Click PLC Communication WiFi https://youtu.be/1cs8O8HLE6Q Integrating an XY-MD02 Sensor with Modbus RTU into Click PLC https://accautomation.ca/integrating-xy-md02-sensor-modbus-rtu-click-plc/ https://youtu.be/fMfWQZ90X8o Click Remote PLC Mobile App https://accautomation.ca/click-remote-plc-mobile-application/ https://youtu.be/vhfcsu_bjdc Mastering Click PLC Communication Modbus RS485! https://accautomation.ca/mastering-click-plc-communication-modbus-rs485/ https://youtu.be/RQ4ik2UoRns CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk CLICK PLCs were designed with simplicity in mind, providing reliable control at a low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications, or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK's simple design, the new CLICK PLUS PLCs offer the same practical control but with surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) include the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

Master Node-Red C2-NRED Control of Click PLC I/O

1K views · Mar 31, 2025 accautomation.ca

Controlling the outputs of a PLC by observing the inputs is a fundamental concept in automation and programming. This guide will examine how the C2-NRED Node-RED module works with the Click PLC inputs and outputs. This is an exciting step into the world of automation and control systems. Imagine efficiently managing inputs and outputs using the C2-NRED module and the Click PLUS PLC. This powerful pairing helps streamline processes and boost efficiency in many different applications. We will explore how these technologies work together and how they can transform control systems. You might wonder how flow and ladder logic programming can control the same output using the same inputs. Stay tuned to learn how the seamless integration of the C2-NRED module and Click PLUS PLC can improve your control processes with greater precision and effectiveness. Let's dive in! More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/master-node-red-c2-nred-control-of-click-plc-i-o/ 00:00 Master Node-Red C2-NRED Control of Click PLC I/O 01:10 What is a PLC Scan? 02:41 C2-NRED Full Control 03:40 Click PLUS PLC Ladder Logic 05:01 Modifying the Flow Program 06:11 Click PLUS PLC Ladder Logic Program Previously, we looked at the following using C2-NRED Node-RED: CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk Unleash Innovation: Node-RED Flow in Click PLC https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ https://youtu.be/JcFX6kK36p4 CLICK PLCs were designed with simplicity in mind, providing reliable control at a low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications, or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK's simple design, the new CLICK PLUS PLCs offer the same practical control but with surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) include the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

Unlock the Power: Faster NODES Install with C2-NRED Node-RED...

8K views · Apr 7, 2025 accautomation.ca

Downloading and installing nodes on our Click PLUS C2-NRED module is not complex to learn, but there are a few items that you must take into consideration. Currently, the C2-NRED module has Node-RED version 3.0 preinstalled, which was initially released on July 14, 2022, and is a stable software version. It uses version 14.1 of Node.js. This is important when determining how the software will interact with the Click backplane. Node-RED is a powerful flow-based development tool for visual programming, particularly suited for the Internet of Things (IoT). One of its biggest strengths lies in its extensive library of nodes, which allows users to perform tasks ranging from simple data manipulation to complex integrations with various hardware and APIs. This information will explore how to find and install nodes in the C2-NRED Node-RED, including considerations for compatibility with different versions. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/faster-nodes-install-with-c2-nred-node-red/ 00:00 Faster NODES Install with C2-NRED Node-RED! 01:15 Understanding Nodes in Node-RED 02:20 Finding Nodes to Install 03:26 Finding NODES Through Manage Palette 05:44 Downloading the Node Version Package 07:40 Installing the Downloaded Node Previously, we looked at the following using C2-NRED Node-RED: CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk Unleash Innovation: Node-RED Flow in Click PLC https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ https://youtu.be/JcFX6kK36p4 Master Node-Red C2-NRED Control of Click PLC I/O https://accautomation.ca/master-node-red-c2-nred-control-of-click-plc-i-o/ https://youtu.be/AGiDeqQ8PTg CLICK PLCs were designed with simplicity in mind, providing reliable control at a low, low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK s simple design, the new CLICK PLUS PLCs offer the same practical control but with some surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) includes the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

Click PLC & AEDES MQTT: What is the Big Deal?

2K views · Apr 28, 2025 accautomation.ca

CLICK PLC C2-NRED Aedes MQTT: Revolutionizing Automation Communication In the rapidly evolving world of industrial automation, efficient communication between devices is crucial for the success of any operation. Enter the CLICK PLC C2-NRED with its innovative Aedes MQTT Broker node. This Node-RED node revolutionizes how we perceive automation networking. You can now install an MQTT Broker in the industrial environment without using a server on your network. This will speed up your MQTT communication. We will install the Node-RED Aedes MQTT broker on our Click PLUS PLC C2-NRED module. The clients will subscribe and publish to this broker. Node-RED nodes, MQTT In and Out, will be used in the C2-NRED. We will also use the BRX Do-More PLC and the Click PLUS MQTT communications to create three connections. Let's get started. For more information, please visit our website. This includes all of the links mentioned in this video. https://accautomation.ca/click-plc-aedes-mqtt-what-is-the-big-deal/ 00:00 Click PLC & AEDES MQTT: What is the Big Deal? 01:18 What is MQTT? 02:01 Integration of Aedes with CLICK PLC C2-NRED 05:21 MQTT IN / OUT in Node-RED (Client) 09:44 BRX Do-More MQTT 13:19 Click PLUS PLC MQTT Previously, we looked at the following using C2-NRED Node-RED: CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk Unleash Innovation: Node-RED Flow in Click PLC https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ https://youtu.be/JcFX6kK36p4 Master Node-Red C2-NRED Control of Click PLC I/O https://accautomation.ca/master-node-red-c2-nred-control-of-click-plc-i-o/ https://youtu.be/AGiDeqQ8PTg CLICK PLCs were designed with simplicity in mind, providing reliable control at a low cost and with a minimal learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications, or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK's simple design, the new CLICK PLUS PLCs offer the same practical control, but with some surprising added features. Using the same free, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs offer hassle-free programming combined with advanced capabilities such as Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) include the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

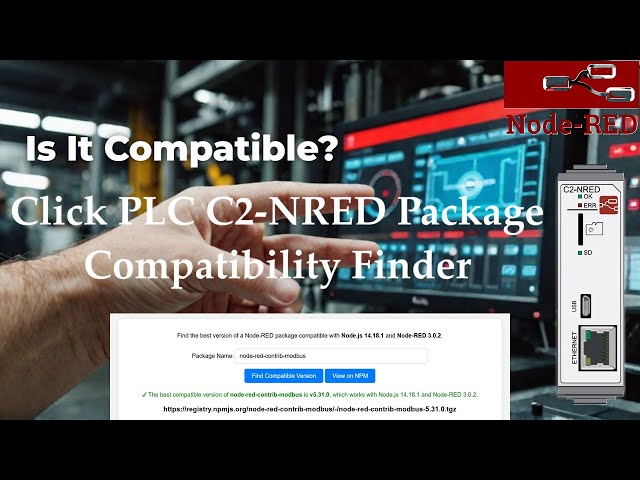

Master the Click PLC C2-NRED Package Compatibility Finder!

2K views · May 12, 2025 accautomation.ca

How to use the C2-NRED Package Compatibility Finder... Are you wondering if your Node-RED program package is compatible with the Click PLUS PLC C2-NRED module? How do you find the correct C2-NRED package? This is the most common frustration with the C2-NRED Node-RED module for the Click PLC. This Node-Red module currently has version 3.0.2 with Node.js 14.18.1. You can spend hours finding a compatible Node-Red package for your industrial control system. Enter the "C2-NRED Package Compatibility Finder" on GitHub. Automation Direct just released this. We will explore the details of using the C2-NRED Package Compatibility Finder. We will be installing the Node-Red Modbus onto our Click PLUS C2-NRED module. Let's take the easy way to find, confirm, download, and install Node-RED packages on our Click PLUS PLC. Let's get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/how-to-use-the-click-plc-c2-nred-package-finder/ C2-NRED Package Compatibility Finder https://automationdirect.github.io/CLICK-PLC/Node-RED/C2-NREDModuleVersionCheck/CompatibiltyCheck.html 00:00 How to Use the Click PLC C2-NRED Package Finder 01:18 Finding Node-RED Packages 02:50 Click PLC C2-NRED Package Compatibility Finder 04:21 Downloading the Node-RED Package 05:28 Installing the Node-RED Package Previously, we looked at the following using C2-NRED Node-RED: CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk Unleash Innovation: Node-RED Flow in Click PLC https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ https://youtu.be/JcFX6kK36p4 Master Node-Red C2-NRED Control of Click PLC I/O https://accautomation.ca/master-node-red-c2-nred-control-of-click-plc-i-o/ https://youtu.be/AGiDeqQ8PTg Click PLC & AEDES MQTT: What is the Big Deal? https://accautomation.ca/click-plc-aedes-mqtt-what-is-the-big-deal/ https://youtu.be/Ilb5IFqOrNo CLICK PLCs were designed with simplicity in mind, providing reliable control at a low, low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK s simple design, the new CLICK PLUS PLCs offer the same practical control but with some surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) includes the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca

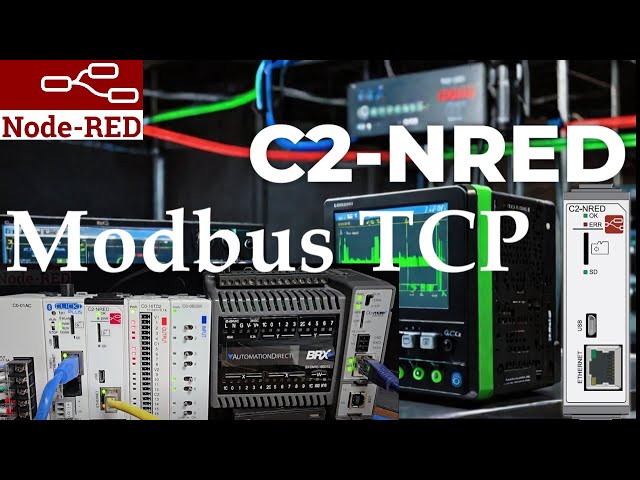

How to Master Modbus TCP Communication with Node-RED?

1K views · May 19, 2025 accautomation.ca

How to Master Modbus TCP Communication with Node-RED? We will now establish communication using Modbus TCP from the C2-NRED module to the Ethernet ports of the BRX Do-More and Click PLCs. Previously, we installed version 5.31.0 of the node-red-modbus-contrib package. We utilized the C2-NRED Package Compatibility Finder to locate and download this Node-RED package. Efficient PLC communication is essential for seamless operations. In this process, we will use the installed Modbus nodes to read 10 registers from the BRX Do-More PLC and write these values to the Click PLUS PLC. This will be done through the Ethernet port on the C2-NRED module. The C2-NRED Node-RED module is a versatile platform for integrating different systems and enhancing the overall efficiency of industrial setups. Let's get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/c2-nred-to-brx-do-more-click-plcs-modbus-tcp/ 00:00 C2-NRED to BRX Do-More & Click PLCs: Modbus TCP! 01:13 Setting up the BRX Do-More PLC 02:46 Node-RED C2-NRED Modbus Flow 04:22 C2-NRED Modbus TCP Flow to Read BRX Do-More PLC 07:39 Setting up the Click PLUS PLC 08:42 C2-NRED Modbus TCP Flow to Write to Click PLUS PLC Previously, we looked at the following using C2-NRED Node-RED: CLICK PLUS C2-NRED: Easy Install for PLC Module! https://accautomation.ca/click-plus-c2-nred-easy-install-for-plc-module/ https://youtu.be/ZFgcVwCYCRk Unleash Innovation: Node-RED Flow in Click PLC https://accautomation.ca/unleash-innovation-node-red-flow-in-click-plc/ https://youtu.be/JcFX6kK36p4 Master Node-Red C2-NRED Control of Click PLC I/O https://accautomation.ca/master-node-red-c2-nred-control-of-click-plc-i-o/ https://youtu.be/AGiDeqQ8PTg Click PLC & AEDES MQTT: What is the Big Deal? https://accautomation.ca/click-plc-aedes-mqtt-what-is-the-big-deal/ https://youtu.be/Ilb5IFqOrNo How to Use the Click PLC C2-NRED Package Finder https://accautomation.ca/how-to-use-the-click-plc-c2-nred-package-finder/ https://youtu.be/q9etRrsnQ9w CLICK PLCs were designed with simplicity in mind, providing reliable control at a low, low cost and with little to no learning curve. This simplicity makes CLICK a perfect solution for small machines, home automation projects, pneumatic applications or anywhere a simple system needs a budget-saving control solution. Building on the original CLICK s simple design, the new CLICK PLUS PLCs offer the same practical control but with some surprising bells and whistles. Using the same FREE, streamlined PLC programming software as its predecessor, the CLICK PLUS PLCs provide no-headache programming combined with advanced capabilities like Wi-Fi communication and data logging. The Click and Click PLUS PLC series can be found at this URL: https://accautomation.ca/series/click-plc/ Features of the new Click PLUS PLC (C2-0xCPU) includes the following: Micro USB DHCP support DNS support Wi-Fi (programming and Modbus TCP) Bluetooth (Wi-Fi) provisioning SD Card (Data Logging) Data Logger Network Time Service MQTT (Publish/Subscribe) Required PLC Password Disable Ports Strong Password Support Disable Ping Response Encrypted Password Transfer We are using the Click and Click PLUS PLCs for several reasons. Here are just a few. - Investment is low for the hardware, and the software is free - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for Modbus RTU, Modbus TCP, etc. - Ability to expand the system with various modules, including RTD and Thermocouple inputs directly. Regards, Garry ACC Automation https://www.accautomation.ca