PLC Program Example – Paint Spraying

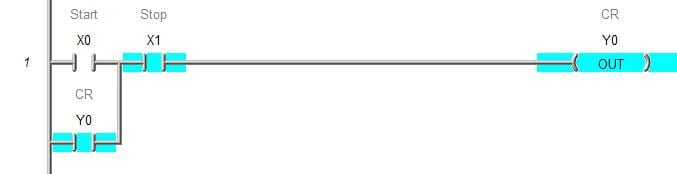

We will look at a PLC basic tutorial of a paint spraying station. Following the five steps to program development, this PLC programming example should fully explain the procedure for developing the PLC program logic. Ladder logic will be our PLC programming language. We will use the Do-more Designer software, which comes with a simulator. … Read more