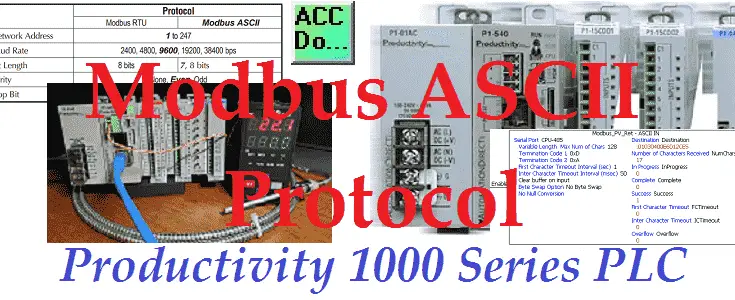

Productivity 1000 PLC Modbus ASCII Protocol

We will not look at the productivity 1000 plc modbus ascii protocol to the Solo process temperature controller. This will be done in ladder logic on our productivity 1000 PLC. Modbus ASCII is a communication method used for transmitting information over serial lines between electronic devices. The device requesting the information is called the Modbus … Read more