Omron CP1H PLC Data Control Instructions

2K views · Oct 15, 2022 accautomation.ca

The data control instructions in the Omron CP1H programmable logic controller are used to manipulate the outputs based upon control conditions. Control is the main purpose of these instructions within the PLC. Instructions include PID (Proportional, Integral, and Derivative), PID with Autotuning, Dead Band Control, Limit, Dead Zone Control, Time Proportional Output, Scaling, etc. We will be looking at some of these instructions in the Omron CP1H PLC. Examples of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-data-control-instructions Previously in this Omron CP1H series we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions https://accautomation.ca/omron-cp1h-data-conversion-instructions Omron CP1H Program Control Instructions https://accautomation.ca/omron-cp1h-program-control-instructions Omron CP1H Table Data Instructions https://accautomation.ca/omron-cp1h-table-data-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built in Analog inputs and outputs - 4 axis control of motion - 4 high speed counters - powerful instruction set (similar to CS anc CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consist of three different units. CP1E is the cost effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H Table Data Instructions

5K views · Oct 20, 2022 accautomation.ca

The Omron CP1H programmable logic controller has several different table data processing instructions. These instructions are used to handle table data, stacks, and other ranges of data. We can define a stack of data. With this data, we can then do the following: add new data by pushing onto the stack, use FIFO (First In First Out), use LIFO (Last In First Out), find the current stack size, and read, overwrite, insert or delete from the stack. Dimension record tables are used to define the length of each record and the number of records. We can then write and read these records. This is ideal for data acquisition projects. Other instructions found in the table data processing instructions include searching, summing, and finding minimum and maximum values. We will be looking at these instructions in the Omron CP1H PLC. Examples of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-table-data-instructions 00:00 Omron CP1H Table Data Instructions 00:18 Table Data Processing Instructions – Omron CP1H 01:01 SET STACK: SSET(630) 03:15 PUSH ONTO STACK: PUSH(632) 05:29 FIRST IN FIRST OUT: FIFO(633) LAST IN FIRST OUT: LIFO(634) 08:20 DIMENSION RECORD TABLE: DIM(631) SET RECORD LOCATION: SETR(635) GET RECORD NUMBER: GETR(636) 10:55 DATA SEARCH: SRCH(181) 12:48 SWAP BYTES: SWAP(637) 14:20 FIND MAXIMUM: MAX(182) FIND MINIMUM: MIN(183) 16:35 SUM: SUM(184) 17:45 FRAME CHECKSUM: FCS(180) 19:28 STACK SIZE READ: SNUM(638) STACK DATA READ: SREAD(639) STACK DATA OVERWRITE: SWRIT(640) STACK DATA INSERT: SINS(641) STACK DATA DELETE: SDEL(642) Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions https://accautomation.ca/omron-cp1h-data-conversion-instructions Omron CP1H Program Control Instructions https://accautomation.ca/omron-cp1h-program-control-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

How to Implement Omron PLC Host Link Protocol

9K views · Oct 16, 2022 accautomation.ca

Hostlink communication protocol is a method developed by Omron for communication to PLCs and other equipment. This ASCII-based protocol is used over RS232 or RS422/RS485. It is a many-to-one implementation which means that you can communicate with up to 32 devices back to a master. (1:N) This communication on the industrial floor can control PLCs, Temperature Controllers, Panel Meters, etc. More information can be obtained from our website: https://accautomation.ca/how-to-implement-the-omron-plc-host-link-protocol/ 00:00 How to Implement Omron PLC Host Link Protocol 00:21 Reviewing the VB6 code 01:27 Running the Code https://www.accautomation.ca

How to Implement the Omron Host Link Protocol Part 2 VBA

2K views · Oct 16, 2022 accautomation.ca

We will not use VBA in Excel to communicate to an Omron PLC. This will use the serial host link protocol. More information can be obtained at our website. https://accautomation.ca/how-to-implement-the-omron-host-link-protocol-part-2-vba/ In Part 1, we used VB6 to communicate from the computer to the PLC. We will now use Visual Basic for Applications (VBA) to accomplish the same task. NETComm will be the serial driver and Excel will be the program that we will use. Using Excel we will have access to the Excel Object Model so we can utilize worksheets, ranges, etc. Part 1: https://accautomation.ca/how-to-implement-the-omron-plc-host-link-protocol/ https://www.accautomation.ca

Implementing the Omron CX Server DDE and Excel

4K views · Oct 16, 2022 accautomation.ca

Utilizing the CX Server DDE Manager will allow us to provide a link to the information in the Omron PLC. This link can be placed on an Excel spreadsheet. Charts, graphs, etc. can be made from the data. We will create links on an excel spreadsheet from a CQM1H and a CP1L PLC. The information will then be displayed as a bar graph comparing the first ten memory areas. More information can be obtained at our website. https://accautomation.ca/implementing-the-omron-cx-server-dde-and-excel/ Dynamic Data Exchange (DDE) is a channel through which correctly prepared programs can actively exchange data and control other applications within Microsoft Windows. The DDE manager will allow us to set up all of the links. 00:00 Implementing the Omron CX Server DDE and Excel 00:15 Starting the CX-Server DDE Manager 00:26 Create a new project in DDE Manager 01:06 Add new device 02:09 Start Office Excel and Set Links 05:05 Running the Excel program ACC Automation https://accautomation.ca

Omron CP1H Table Data Instructions

1K views · Oct 16, 2022 accautomation.ca

The Omron CP1H programmable logic controller has several different table data processing instructions. These instructions handle table data, stacks, and other data ranges. We can define a stack of data. With this data, we can then do the following: add new data by pushing onto the stack, use FIFO (First In First Out), use LIFO (Last In First Out), find the current stack size, and read, overwrite, insert or delete from the stack. Dimension record tables are used to define the length of each record and the number of records. We can then write and read these records. This is ideal for data acquisition projects. Other instructions found in the table data processing instructions include searching, summing, and finding minimum and maximum values. We will be looking at these instructions in the Omron CP1H PLC. Examples of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-table-data-instructions 00:00 Omron CP1H Table Data Instructions 00:18 Table Data Processing Instructions – Omron CP1H 01:01 SET STACK: SSET(630) 03:15 PUSH ONTO STACK: PUSH(632) 05:29 FIRST IN, FIRST OUT: FIFO(633) LAST IN, FIRST OUT: LIFO(634) 08:20 DIMENSION RECORD TABLE: DIM(631) SET RECORD LOCATION: SETR(635) GET RECORD NUMBER: GETR(636) 10:55 DATA SEARCH: SRCH(181) 12:48 SWAP BYTES: SWAP(637) 14:20 FIND MAXIMUM: MAX(182) FIND MINIMUM: MIN(183) 16:35 SUM: SUM(184) 17:45 FRAME CHECKSUM: FCS(180) 19:28 STACK SIZE READ: SNUM(638) STACK DATA READ: SREAD(639) STACK DATA OVERWRITE: SWRIT(640) STACK DATA INSERT: SINS(641) STACK DATA DELETE: SDEL(642) Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing, and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions https://accautomation.ca/omron-cp1h-data-conversion-instructions Omron CP1H Program Control Instructions https://accautomation.ca/omron-cp1h-program-control-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4-axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet, and CP1H is the position control and comprehensive programmable logic controller. We will be looking at the CP1H for this series, but most of the information can also be applied to the CP1E and the CP1L controllers. https://www.accautomation.ca

Omron C20K, C28K, C40K, C60K Troubleshooting

29K views · Oct 15, 2022 accautomation.ca

The Omron C20K, C28K, C40K, and C60K shoebox programmable logic controllers have been discontinued since March of 2002. These Omron ‘K’ series PLCs were popular controllers and have been in installations for over 25 years. We will take a look at this Omron PLC and review some troubleshooting techniques. Planning for the eventual fatal failure of the CPU will also be discussed. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-c20k-c28k-c40k-c60k-troubleshooting The following are the manuals for the ‘K’ series PLCs. You will note that the C20 manual is also listed. This is because the ‘K’ series could use the C20 expansion modules. The C20 was also referred to as a ‘Flatpack’ PLC. Operation Manual – Sysmac C20K/C28K/C40K/C60K Programmable Controllers http://www.omronkft.hu/nostree/pdfs/plc/cxxk/w146e15_c20k_c28k_c40k_c60k_operation_manual.pdf This manual will go through the instruction set as well as how to program the unit using the handheld unit. (3G2C7-PRO15-E) Installation Guide – Sysmac C20K/C28K/C40K/C60K Programmable Controllers http://omronkft.hu/nostree/pdfs/plc/cxxk/w147e31_c20k_c28k_c40k_c60k_installation_guide.pdf This manual will review the installation and troubleshooting techniques on this programmable controller. C20 Programmable Controller – Sysmac C-Series – User’s Manual http://www.omronkft.hu/nostree/pdfs/plc/c20/w083e15_c20_user_manual.pdf This manual includes the installation, instruction set, and troubleshooting of the C20 PLC. 00:00 Omron C20K, C28K, C40K, C60K Troubleshooting 00:58 Omron Manuals 01:56 Hardware – Omron Troubleshooting 03:00 Errors on the CPU 04:44 Fuse Change 05:19 Relay Change 05:30 Battery Change 06:00 Troubleshooting with the handheld unit 09:47 Updating the Omron Controller https://www.accautomation.ca

Omron CP1H PLC System Hardware

5K views · Oct 15, 2022 accautomation.ca

We will now look at the system hardware of the Omron CP1H controller. The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. Let’s start by looking at the CP1H hardware. The CP1 series is designed with the same basic architecture as the CS and CJ Series. The special I/O units and CPU bus units of the CJ series can then be used. Always use CPM1A expansion units and CPM1A expansion I/O units when expanding the I/O capacity. This is the start of the Omron CP1H Series to get you familiar with this programmable logic controller. (PLC) More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-system-hardware/ This series on the Omron Sysmac CP1H Controller (PLC) will go step by step through learning how to use this innovative unit. 00:00 Omron CP1H PLC System Hardware 00:51 Omron CP1H Hardware 01:50 CP1H Terminal Strips 02:26 Battery Location 03:04 Programming Port / Dip Switch Settings 04:08 Communication Boards 05:12 Expansion Port 06:38 Model and Serial Numbers Omron CP1H – System Hardware and Programming Manuals https://accautomation.ca/omron-cp1h-system-hardware/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules https://www.accautomation.ca

Omron CP1H PLC CX-Programmer

7K views · Oct 15, 2022 accautomation.ca

We will now look at the Omron cx programmer software to program our CP1H PLC. The Omron CP1H series of programmable logic controllers are programmed from CX-Programmer. CX-Programmer is part of the Omron CX-One Factory Automation Integrated Tool Package. This software package integrates support software for Omron PLC and other components. Traditionally you had to purchase and install individual support software compatible with each unit and then connect to each PLC and component. CX-One FA Integrated Tool Package eliminates this by providing one package for operating and setup of Omron PLCs, Special I/O units, components, networking start-up, and monitoring. This improves the efficiency of the PLC system start-ups. We will be looking at starting CX-Programmer within the CX-One Software package and starting a new project for our CP1H PLC. More information can be obtained on our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-cx-programmer 00:00 Omron CX-Programmer 00:25 Omron CX-Programmer Introduction Guide 01:26 Starting cx-programmer 02:19 Starting new PLC program 04:33 PLC program window 05:20 PLC ladder programming 10:08 Compile PLC ladder program The purpose of this Omron CP1H Series is to get you familiar with this programmable logic controller. (PLC) Previously in this Omron CP1H series, we looked at the following: System Hardware http://accautomation.ca/omron-cp1h-system-hardware/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Establish Communication

7K views · Oct 15, 2022 accautomation.ca

We will now establish Omron cp1h communication using the built-in USB connection. CX-Programmer will be used to communicate. The Omron CP1H series of programmable logic controllers are programmed from CX-Programmer. CX-Programmer is part of the Omron CX-One Factory Automation Integrated Tool Package. We will now establish communication with our CP1H PLC using CX-Programmer. We will be using the USB connection (Built into the CPU) as well as an RS485 connection using the CP1W-CIF11 module. The Start-Stop and Jog circuit that we developed last time will be transferred to the PLC unit. We will then verify that the program in the PLC is the same as the program logic in CX-Programmer. More information can be obtained on our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-establish-communication/ 00:00 Omron CP1H Programming Communication 00:35 Hardware - USB and RS485 communication to Omron CPU 01:43 RS485 to USB Converter 02:30 Serial RS485 (Similar to RS232) Establish Communication 06:15 Transfer program to Omron PLC 08:08 Verify program in PLC 09:10 USB port to Omron programming software The purpose of this Omron CP1H Series is to get you familiar with this programmable logic controller. (PLC) Previously in this Omron CP1H series, we looked at the following: System Hardware http://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer http://accautomation.ca/omron-cp1h-cx-programmer/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Setting, Forcing and Online Editing

1K views · Oct 15, 2022 accautomation.ca

We will now look at online editing, setting, and forcing that can be done on the Omron CP1H controller. The Omron CP1H series of programmable logic controllers are capable of online programming. This is when the PLC is solving logic and at the end of the scan, programming logic is added or modified. The next scan will now solve the new or modified logic in the PLC. CX-Programmer can also set or force inputs and outputs in the controller. This is usually used for troubleshooting and testing the PLC logic. We will use the Start Stop and Jog circuit that we have developed to test the program in the PLC. Forcing and setting the inputs and outputs will demonstrate to us the operation of the logic. Online programming (online editing) will also be done with our CP1H controller. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ 00:00 Omron CP1H PLC Setting, Forcing and Online Editing 01:25 Modes of the Controller – Omron CP1H Online Editing 03:20 Forcing On, Forcing Off 07:31 Omron Online Edit Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Numbering Systems and Addressing

10K views · Oct 15, 2022 accautomation.ca

We will now look at the Omron numbering systems and addressing in the CP1H PLC. The Omron CP1H series of programmable logic controllers have a fixed input and output addressing system. Every PLC has its own way of addressing its inputs and outputs. We will be looking at how the CP1H series of controller addresses its inputs and outputs. Numbering systems used in this controller will also be looked at as well as addressing. Addressing can be direct or indirect. We will look at how this can be accomplished using examples in the CP1H controller. More information can be obtained on our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing 00:00 Omron numbering systems 00:35 Omron IO addressing 01:10 Omron memory area 03:25 Hardware monitor areas 05:48 Online monitor areas 11:25 Indirect move addressing Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Programming Timers

6K views · Oct 15, 2022 accautomation.ca

The Omron CP1H series of programmable logic controllers are capable of having 4096 timers. There are twelve different timing instructions in the PLC. Six binary and six BCD instructions for the set values of the timers separate the six basic instructions. The memory area for timers has separate areas for the Timer PVs (Present values) and the Timer Completion Flags. We will be looking at the timer instructions in the CP1H along with some programming examples. The secret to using timers is a post that will go over timing charts. It is a good place to understand how timing charts can assist you in programming timers. The Secret of Using Timers https://accautomation.ca/the-secret-of-using-timers/ https://www.youtube.com/watch?v=Bt6i8G8P0Fk More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-timers Previously in this Omron CP1H PLC series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Programming Counters

3K views · Oct 15, 2022 accautomation.ca

The Omron CP1H series of programmable logic controllers are capable of having 4096 basic counters. There are two basic counter instructions in the PLC. Each of the basic instructions can be either binary or BCD. The memory area for counters has separate areas for the Counter PVs (Present values) and the Counter Completion Flags. We will be looking at the basic Counter instructions in the CP1H along with some programming examples. The secret to using counters is a post that will go over timing charts. It is a good place to understand how timing charts can assist you in programming counters. The Secret of Using Counters https://accautomation.ca/the-secret-of-using-counters/ https://www.youtube.com/watch?v=pyNNKRA_xK8 More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-counters Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Data Movement Instructions

3K views · Oct 15, 2022 accautomation.ca

Every program usually has some kind of data movement. This is the ability to transfer information from one area of the controller to another. The Omron CP1H series of programmable logic controllers provide several different ways to manipulate this information. We will be looking at several different ways in which data movement can happen with some programming examples. Data movement in the Omron CP1H does not care what is in the bits that make up the word. It will just send or receive this information. Remember that it is usually the instruction used, that determines how the information in the memory is determined. We will be covering several different data movement instructions. A full explanation can be obtained by using the help menu in the CX-Programmer software or the Programming Manual for the CP1H. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-data-movement Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters 00:00 Omron CP1H PLC Data Movement Instructions 00:51 MOVE: MOV(021) 02:10 MOVE NOT: MVN(022) 03:02 DOUBLE MOVE: MOVL(498) 03:47 DOUBLE MOVE NOT: MVNL(499) 04:42 MOVE BIT: MOVB(082) 05:58 MOVE DIGIT: MOVD(083) 07:11 MULTIPLE BIT TRANSFER: XFRB(062) 08:10 BLOCK TRANSFER: XFER(070) 09:17 BLOCK SET: BSET(071) 10:21 DATA EXCHANGE: XCHG(073) 11:30 DOUBLE DATA EXCHANGE: XCGL(562) 12:18 SINGLE WORD DISTRIBUTE: DIST(080) 13:23 DATA COLLECT: COLL(081) 14:27 MOVE TO REGISTER: MOVR(560) 14:55 MOVE TIMER/COUNTER PV TO REGISTER: MOVRW(561) There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC Compare Instructions

24K views · Oct 15, 2022 accautomation.ca

We will now look at the compare instructions available on the Omron CP1H controller. Just about every program usually has some data comparison instruction. This is the ability to compare information from one area of the controller to another and act on results. The Omron CP1H series of programmable logic controllers provide several different ways to compare the information. We will be looking at several different ways in which we can do this with some programming examples. Sometimes the instruction used for data comparison in the Omron CP1H will determine the kind of data that we are comparing. You must look at the individual instructions to determine if this is the case or not. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-compare-instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

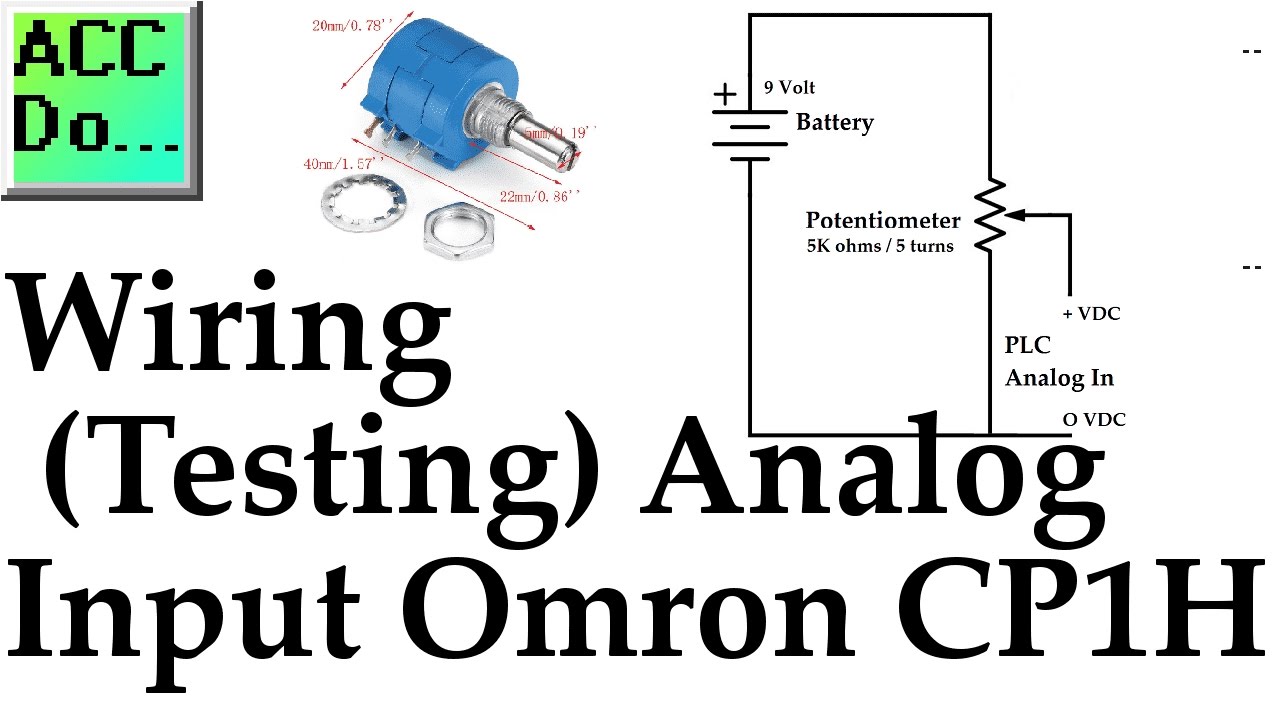

Wiring Testing Analog PLC Input Omron CP1H

3K views · Oct 15, 2022 accautomation.ca

We will now look at wiring analog plc input Omron CP1H plc. We will show the wiring of an analog (0-10VDC) input into a PLC. The PLC is an Omron CP1H. We will utilize the built-in 24VDC power supply and wire it directly into the inputs of the PLC. The discrete input is looking for voltage between the input and the common point for the input. Here is a link for additional information on the Omron CP1H PLC. https://accautomation.ca/omron-cp1h-system-hardware/ More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/how-plc-inputs-work/ https://accautomation.ca/programming/plc-beginners-guide/ 00:00 Wiring Testing Analog PLC Input Omron CP1H 00:18 Analog Input Wiring Diagram 00:39 PLC wiring diagram 01:25 CX-Programmer Monitoring - Scaled Input 02:12 Testing the analog input to the Omron CP1H ACC Automation https://accautomation.ca/

Omron CP1H Data Shifting Instructions Part 2

4K views · Oct 15, 2022 accautomation.ca

We will now look at data shifting instructions in the Omron CP1H controller. PLC programming is all about how we can manipulate the information stored in the PLC. We have already looked at timers, counters, moves, and comparison instructions. Data shifting is a different concept that will move bits and words around in memory. This is necessary usually for tracking purposes. The word or bit will represent the product or information. As this information is triggered to shift to a new location we can use this to activate items later in the process. A typical example of this would be parts on a conveyor belt. As the part is detected on one end it will turn on a bit in a register. The conveyor movement is usually picked put by an encoder and shifts this bit in the register in sync with the conveyor movement. At the other end of the conveyor belt, we can see the bit position and do something with this information. We can use this information to count, reject, etc. Looking at the entire register full of bits, we can determine everything on the conveyor and its position. We will be looking at the data shifting instructions in the Omron CP1H PLC. Examples of some of the instructions will be presented. The instructions are used to shift data within or between words, but in different amounts and directions. Part 1 https://youtu.be/dCM_1Rquobc More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-data-shifting-instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H Data Shifting Instructions Part 1

8K views · Oct 15, 2022 accautomation.ca

We will now look at data shifting instructions in the Omron CP1H controller. PLC programming is all about how we can manipulate the information stored in the PLC. We have already looked at timers, counters, moves, and comparison instructions. Data shifting is a different concept that will move bits and words around in memory. This is necessary usually for tracking purposes. The word or bit will represent the product or information. As this information is triggered to shift to a new location we can use this to activate items later in the process. A typical example of this would be parts on a conveyor belt. As the part is detected on one end it will turn on a bit in a register. The conveyor movement is usually picked put by an encoder and shifts this bit in the register in sync with the conveyor movement. At the other end of the conveyor belt, we can see the bit position and do something with this information. We can use this information to count, reject, etc. Looking at the entire register full of bits, we can determine everything on the conveyor and its position. We will be looking at the data shifting instructions in the Omron CP1H PLC. Examples of some of the instructions will be presented. The instructions are used to shift data within or between words, but in different amounts and directions. Part 2 https://youtu.be/b-u_BojqhUQ More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-data-shifting-instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H Math Instructions

3K views · Oct 15, 2022 accautomation.ca

Programmable logic controllers are not typically known for their math ability. Modern PLC controllers now come with several math instructions to expand the ability to perform math routines. Every controller has different methods to handle math with varying systems of numbering. Binary, BCD (Binary Coded Decimal), and floating-point single and double are examples of some numbering systems. The following is a post on what everybody should know about PLC numbering systems. https://accautomation.ca/what-everybody-ought-to-know-about-plc-programmable-logic-controller-numbering-systems/ If you subscribe to our website, you will get a free copy of the article on numbering systems, which includes understanding the floating point. You must refer to the programming manual of the controller that you are programming for specific math instruction information. We will be looking at some of the math instructions in the Omron CP1H PLC. Examples of some of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-math-instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing, and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - robust instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet, and CP1H is the position control and comprehensive programmable logic controller. We will be looking at the CP1H for this series, but most of the information can also be applied to the CP1E and the CP1L controllers. ACC Automation https://www.accautomation.ca

Omron CP1H Data Conversion Instructions

4K views · Oct 15, 2022 accautomation.ca

We will now look at data conversion instructions in the Omron Cp1H Controller. Programmable logic controller programming is all about manipulating the bits within the memory of the controller. Sometimes we need to convert from one form to another. This is where we will use data conversion instructions. BCD to Binary, Line to Column, Grey Scale, and Multiplexing are just some of the data conversion instructions. We will be looking at some of these instructions in the Omron CP1H PLC. Examples of some of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-data-conversion-instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions 00:00 Omron CP1H Data Conversion Instructions 01:42 BCD-TO-BINARY: BIN(023) 02:47 BINARY-TO-BCD: BCD(024) 03:20 2’S COMPLEMENT: NEG(160) 04:53 DATA DECODER: MLPX(076) 06:55 DATA ENCODER: DMPX(077) 08:53 ASCII CONVERT: ASC(086) 11:33 LINE TO COLUMN: COLM(064) 13:45 GRAY CODE CONVERT: GRY(474) There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high-performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. http://www.accautomation.ca

Implementing the Omron Host Link Protocol VB.Net

29K views · Oct 15, 2022 accautomation.ca

We will be implementing the Omron host link protocol vb.net. Hostlink communication protocol is a method developed by Omron for communication to PLCs and other equipment. This ASCII-based protocol is used over RS232 or RS422/RS485. It is a many-to-one implementation which means that you can communicate with up to 32 devices back to a master. (1:N) This communication on the industrial floor can control PLCs, Temperature Controllers, Panel Meters, etc. The Omron CP1H plc will be used with a CP1W-CIF11 (RS485) communication serial link adapter. We will also use a USB-485M Universal Serial Bus to RS485 adapter from automation direct. The video at the end of this post will demonstrate the communications by reading 10 registers from the DM area of the PLC. More information can be obtained on our website. This includes all of the links mentioned in this video. https://accautomation.ca/implementing-the-omron-host-link-protocol-vb-net Previously we used VB6 (Visual Basic 6) to implement the Omron Host Link Protocol to communicate to our programmable logic controller. (PLC) http://accautomation.ca/how-to-implement-the-omron-plc-host-link-protocol/ In part 2 we used Visual Basic for Applications (VBA) to accomplish our host link serial communication. http://accautomation.ca/how-to-implement-the-omron-host-link-protocol-part-2-vba/ We will now look at using VB.Net to establish and retrieve information in and out of the PLC using host link. (C mode commands) ACC Automation https://accautomation.ca/

Omron CP1H Program Control Instructions

5K views · Oct 15, 2022 accautomation.ca

The Omron CP1H programmable logic controller has several different ways to control the program and the way in which your program executes. Sequence control, Subroutines, and Step instructions can be used. These are just a few ways in which the controller will execute your logic using a synchronous PLC scan. Understanding the PLC program scan will explain the synchronous and asynchronous program scanning. https://accautomation.ca/understanding-the-plc-program-scan/ https://www.youtube.com/watch?v=_mDJcXfGJMk Interlocks, Jumps, For Next Loops, Subroutines and Step instructions are some of the ways in which we can control our program in the PLC. We will be looking at some of these instructions in the Omron CP1H PLC. Examples of some of the instructions will be presented. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-program-control-instructions 00:00 Omron CP1H Program Control Instructions 00:28 INTERLOCK and INTERLOCK CLEAR: IL(002) and ILC(003) 01:45 JUMP and JUMP END: JMP(004) and JME(005) 03:43 FOR-NEXT LOOPS: FOR(512)/NEXT(513) 06:28 Subroutines 09:07 Step Instructions Previously in this Omron CP1H series, we looked at the following: System Hardware https://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions https://accautomation.ca/omron-cp1h-data-conversion-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC AdvancedHMI Communication

7K views · Oct 15, 2022 accautomation.ca

We will now use AdvancedHMI to communicate to our Omron CP1H controller. Advanced HMI is a powerful, adaptable HMI/SCADA (Supervisory Control and Data Acquisition) development package that takes advantage of Visual Studio. There is no coding required and you can simply drag and drop items onto the page. The best thing is that the software is free. We will look at using AdvancedHMI with the Omron CP1H PLC. Our sample CP1H PLC program will use buttons and indicators to control a start/stop jog circuit. An analog input into the PLC will be scaled and displayed on a gauge on our AdvancedHMI screen. We will also write information to our 7 segment display on the CPU from our AdvancedHMI screen. This communication will be done using Omron serial host link protocol over an RS485 serial cable. The AdvancedHMI package will run on a windows PC and communicate out the port using a USB to RS485 adapter. AdvancedHMI can communicate to many devices. The CP1H PLC can communicate Host Link (C Mode Commands) Serial – RS232, RS485, RS422. It can also communicate Ethernet FINS via a communications module. Communications drivers currently included in AdvancedHMI are as follows. These drivers are fully accessible via VB or C# code: • Allen Bradley DF1 RS232 Driver • Allen Bradley Ethernet/IP Driver for SLC, MicroLogix, ControlLogix, and CompactLogix • Beckhoff TwinCAT Driver • ModbusTCP Driver • Modbus RTU Driver • Omron Ethernet FINS Driver – Ethernet for newer controllers such as CP1H with Ethernet module • Omron Serial FINS Driver – Serial (RS232 / RS485) for newer controllers such as CP1H • Omron Serial HostLink Driver – Serial (RS232 / RS485) for controllers such as CQM1, C200H, K-Series (C28K), C200, etc More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-advancedhmi-communication Previously in this Omron CP1H series, we looked at the following: System Hardware http://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer https://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication https://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing https://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing https://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers https://accautomation.ca/omron-cp1h-timers Omron CP1H Counters https://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement https://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions https://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions https://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions https://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions https://accautomation.ca/omron-cp1h-data-conversion-instructions Omron CP1H Program Control Instructions https://accautomation.ca/omron-cp1h-program-control-instructions Omron CP1H Table Data Instructions https://accautomation.ca/omron-cp1h-table-data-instructions Omron CP1H Data Control Instructions https://accautomation.ca/omron-cp1h-data-control-instructions There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. https://www.accautomation.ca

Omron CP1H PLC to C-More HMI EA9 RHMI Communication

7K views · Oct 13, 2022 accautomation.ca

We will now look at the omron plc to cmore hmi communication. This headless HMI will use an android app to display the Omron PLC values on the cmore hmi. Our sample CP1H PLC program will use buttons and indicators to control a start/stop jog circuit. An analog input into the PLC will be scaled and displayed on a gauge and numeric display on our HMI screen. We will also write information to our 7 segment display on the CPU from our HMI screen. Omron serial host link protocol will be used to communicate over an RS485 serial cable. We will demonstrate remote access using our windows and android device. Let’s get started. More information can be obtained on our website. This includes all of the links mentioned in this video. http://accautomation.ca/omron-cp1h-to-c-more-ea9-rhmi-communication 00:00 Introduction 00:32 Hardware 02:43 Omron PLC Program Review 05:12 CMore Program Review 09:05 HMI Web Server / Remote Access 13:40 Testing the program - Windows remote and Android Remote HMI 18:25 Conclusion The C-More EA9 Series of human-machine interfaces (HMI) provides a way for the operator to control and will perform a lot of additional items. The free programming software is very user friendly and fully featured. Here are some of the additional items that this robust and powerful HMI can do besides communicating with programmable logic controllers (PLCs). Send Email – This includes authentication for the email client protocol Log Data – This can log data files to the internal memory or an external thumb drive (32G) FTP Server – Use file transfer protocol to retrieve information from the HMI to a network. This can be done automatically with a batch file. Web Server – This HMI can be a web server on your network Remote Internet Access – Windows, Android, and IOS operating systems have the ability to take advantage of this remote access to the HMI. The programs are free and fully functional. Previously in this Omron CP1H series, we looked at the following: System Hardware http://accautomation.ca/omron-cp1h-system-hardware/ CX-Programmer http://accautomation.ca/omron-cp1h-cx-programmer/ Establish Communication http://accautomation.ca/omron-cp1h-establish-communication/ Omron CP1H Setting, Forcing and Online Editing http://accautomation.ca/omron-cp1h-setting-forcing-and-online-editing/ Omron CP1H Numbering Systems and Addressing http://accautomation.ca/omron-cp1h-numbering-systems-and-addressing/ Omron CP1H Timers http://accautomation.ca/omron-cp1h-timers Omron CP1H Counters http://accautomation.ca/omron-cp1h-counters Omron CP1H Data Movement http://accautomation.ca/omron-cp1h-data-movement Omron CP1H Compare Instructions http://accautomation.ca/omron-cp1h-compare-instructions Omron CP1H Data Shifting Instructions http://accautomation.ca/omron-cp1h-data-shifting-instructions Omron CP1H Math Instructions http://accautomation.ca/omron-cp1h-math-instructions Omron CP1H Data Conversion Instructions http://accautomation.ca/omron-cp1h-data-conversion-instructions Omron CP1H Program Control Instructions http://accautomation.ca/omron-cp1h-program-control-instructions Omron CP1H Table Data Instructions http://accautomation.ca/omron-cp1h-table-data-instructions Omron CP1H Data Control Instructions http://accautomation.ca/omron-cp1h-data-control-instructions Omron CP1H AdvancedHMI Communication http://accautomation.ca/omron-cp1h-advancedhmi-communication https://youtu.be/5_FZ61Ep6u0 There are several reasons why we are using the Omron CP1H Controller. Here are just a few. - Standalone PLC with built-in I/O - Communication ability - Ethernet Port, RS232, RS485 - support for protocols such as Modbus, Host Link, ASCII (No Protocol) - Built-in Analog inputs and outputs - 4 axis control of motion - 4 high-speed counters - powerful instruction set (similar to CS and CJ series) - Ability to expand the system with a variety of modules The Omron CP1 series of programmable logic controllers consists of three different units. CP1E is the cost-effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well. http://www.accautomation.ca

Omron CP1H PLC to C-More Micro HMI Communication

69K views · Oct 12, 2022 accautomation.ca

The omron plc hmi communication can easily be achieved using the C-More Micro HMI. We will connect the EA3-T4CL cmore micro HMI screen to the Omron CP1H PLC. The devices will communicate serially via an RS485 interface. We will demonstrate reading and writing bits and words from the HMI unit. Let’s get started. More information can be obtained on our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-cp1h-to-c-more-micro-hmi-communication 00:00 Introduction 00:33 Hardware CP1H and EA3-T4CL 02:21 Communication Hardware 04:23 PLC Program 07:04 HMI Program 12:38 HMI Simulation 14:08 Testing and monitoring our project 15:44 Conclusion The C-More Micro HMI panel is a series of human-machine interfaces (HMI) that provide a way for the operator to control and view your programmable logic controller. (PLC) The free C-more microprogramming software is user friendly and fully featured. C-more Micro panels can easily display text, graphics, and bitmaps to effectively communicate critical data to your operator. Previously we have discussed the following in our C-More Micro HMI Panel: System Hardware https://accautomation.ca/c-more-micro-hmi-system-hardware Unboxing and Review Video https://youtu.be/_uCcALMqYlM Installing the Software https://accautomation.ca/c-more-micro-hmi-installing-the-software https://youtu.be/BIGrOvxlDTI - Update Automation Direct Software C More Micro Software Video https://youtu.be/MNjTpirZs1s System Setup Screens https://accautomation.ca/c-more-micro-hmi-system-setup-screens https://youtu.be/KolqJkKKhaA First Program https://accautomation.ca/c-more-micro-hmi-first-program https://youtu.be/FsUe-b3JSns First Program Part 2 PLC to/from Panel https://accautomation.ca/c-more-micro-hmi-first-program-part-2 https://youtu.be/GDCDTV0_vr0 Common Screen Menu https://accautomation.ca/c-more-micro-hmi-common-screen-menu https://youtu.be/Y5Xj3w0kY5M Simulate Project https://accautomation.ca/c-more-micro-hmi-simulate-project https://youtu.be/cLyDmpFisMc Object List Shapes https://accautomation.ca/c-more-micro-hmi-object-list-shapes https://youtu.be/Th6gmpJXHjw Object Buttons and Indicators https://accautomation.ca/c-more-micro-hmi-object-buttons-and-indicators https://youtu.be/K-SJnSr-yKo Object Numeric Entry https://accautomation.ca/c-more-micro-hmi-object-numeric-entry https://youtu.be/xwacon41ckw Object Meters and Graphs https://accautomation.ca/c-more-micro-hmi-object-meters-and-graphs https://youtu.be/fNcf0i0NX18 Object Bitmap https://accautomation.ca/c-more-micro-hmi-object-bitmap https://youtu.be/LXUoVhga5rc Object Recipe https://accautomation.ca/c-more-micro-hmi-object-recipe https://youtu.be/TicMrs0-DEU Object Text https://accautomation.ca/c-more-micro-hmi-object-text https://youtu.be/xi2_-3aBWkU There are several reasons that we are using the EA3-T4CL C-More Micro Panel. Here are a few: • Touch screen display • Free downloadable programming software • 482 x 272-pixel display (WQVGA) with up to 40 lines by 80 characters of text and graphics • 32K colours • 14MB memory • Built-in USB type Micro-B programming port • Built-in RJ45 Ethernet Port • Built-in 15-pin serial communications port • Built-in RJ12 serial communications port • Built-in Alarm Control setup that activates beep, back-light flash, customized alarm banner, and red LED blinking • 0 to 50 °C (32 to 122 °F) operating temperature range (IEC 60068-2-14) • NEMA 4/4X, IP65 compliant when mounted correctly, indoor use only • UL, cUL & CE agency approvals • 2-year warranty from date of purchase https://www.accautomation.ca

Omron PLC Node-RED Serial Communication

25K views · Oct 12, 2022 accautomation.ca

PLC manufacturers have their own proprietary protocols. These methods of communication will allow you to program the controller. Other protocols will allow you to collect and log information from the programmable logic controller. Node-RED can read and write to the Omron controller using special protocol commands. We will connect Node-RED to the Omron CP1H PLC. A serial RS485 interface will be used for communication with the industrial controller. We will demonstrate reading and writing using Host Link (C-mode commands) to the Omron PLC. Let’s get started. More information can be obtained at our website. This includes all of the links mentioned in this video. https://accautomation.ca/omron-plc-node-red-serial-communication/ Purchase your USB to RS-485 serial adapter from the following affiliate link. https://amzn.to/35UNc6v In this series, we started using Node-RED in some of the following ways: The entire series can be viewed here: https://accautomation.ca/series/node-red-iot-enabling-software/ Installing the Windows Software https://accautomation.ca/node-red-installing-the-windows-software/ https://youtu.be/xGzH2Hv31WA Modbus RTU / TCP Communication https://accautomation.ca/node-red-modbus-rtu-tcp-communication/ https://youtu.be/yX1w5vcV6cc User Interface - Dashboards https://accautomation.ca/node-red-user-interface-dashboards/ https://youtu.be/8zAG2wXwGOc SQL Database Log https://accautomation.ca/node-red-sql-database-log-modbus-logging/ https://youtu.be/QHjcNj1S_Mo SQL Database Spreadsheet Connection https://accautomation.ca/node-red-sql-database-spreadsheet-connection/ https://youtu.be/Cd3LvhoMaCI Install Node-RED on Raspberry Pi 4 https://accautomation.ca/install-node-red-on-raspberry-pi-4/ https://youtu.be/KleNtxvJkU4 Do-More PLC Node-RED HTTP Request https://accautomation.ca/do-more-plc-node-red-http-request/ https://youtu.be/m-p28H9Fl5s Simple Click Data Logging https://accautomation.ca/simple-click-data-logging-node-red/ https://youtu.be/RmSn4ZSPSmg Node-RED Modbus TCP Handling Errors https://accautomation.ca/node-red-modbus-tcp-handling-errors/ https://youtu.be/CgsJozTr-8w Raspberry Pi Serial Port Programming https://accautomation.ca/raspberry-pi-serial-port-programming/ https://youtu.be/SAY8H3SBl-8 We will continue with the following: Omron PLC Node-RED Serial Communication 00:00 Omron PLC Node-RED Serial Communication 01:09 Omron C-mode (Host Link) 02:17 Omron C-mode (Host Link) Command/Response Formats 03:46 Omron C-mode (Host Link) Command Codes 05:02 CP1W-CIF11 RS-422A/485 Option Boards 06:16 Waveshare USB to RS485 Converter 06:40 Omron CP1H Program and Settings 09:12 Node-RED Program Nodes Required 10:23 Node-RED Omron Serial Read Flow 14:54 Omron Hardware and USB to RS485 Converter 16:07 Executing the Node-RED Flow to Read from the Omron 18:05 Node-RED Omron Serial Write Flow 19:48 Executing the Node-RED Flow to Write to the Omron There are several reasons why we are using Node-RED. Here are just a few. - Built on top of the most dependable programming language, JavaScript. - JavaScript is flexible and easy to work with on web browsers, server-side, IoT, IIoT projects, and more. - Visual flow type interface making programming easy. - Node will allow JavaScript code to run directly on a computer. - Node-RED is a free, open-source logic engine. - Connect to PLC, PAC, Temperature Controllers, and Process Controllers using standard protocols. - Save and read from databases - Easily make the Internet of Things (IoT, IIoT) industrial solutions. Node-RED provides the ability for you to quickly create custom control solutions. https://accautomation.ca/

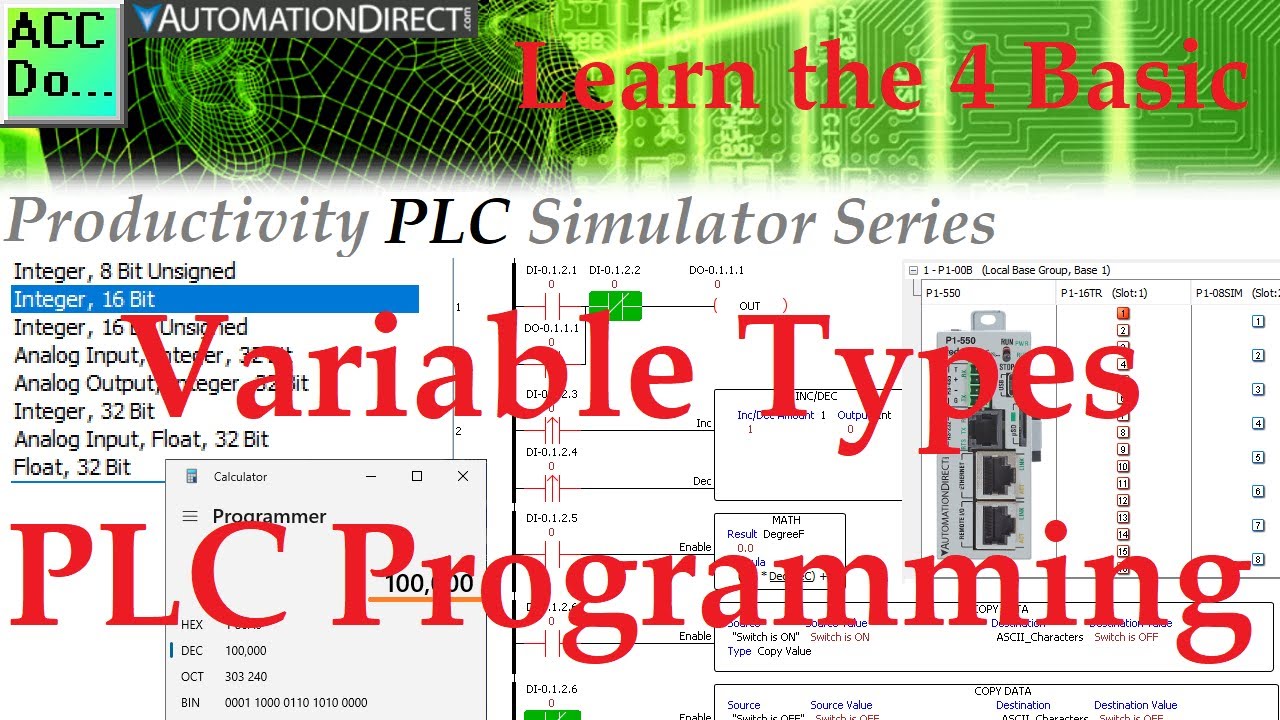

Learn the 4 Basic Variable Types in PLC Programming

7K views · Jan 23, 2023 accautomation.ca

There are four fundamental variable types in PLC programming: Boolean, Integer, Real, and String. This is a universal concept for all PLC programming but needs to be clarified due to the acronyms and various names used by manufacturers and PLC hardware. Your controller programming manual will help you understand the terms of the variables in your hardware. It is essential to understand the different types of variables available to you, the programmer. We will explore each of the four variable types, breaking down what they are and how they are used in programming your controller. Let's dive in! Detailed information and links can be found on the corresponding post located here. https://accautomation.ca/learn-4-basic-variable-types-in-plc-programming/ 00:00 Learn 4 Basic Variable Types in PLC Programming 00:58 Boolean (On / Off) PLC Variable 02:10 Integer (Number) PLC Variable 03:51 Real (Very Large or Small Number) PLC Variable 04:46 String (Character) PLC Variable Here are the controllers that we have covered at ACC Automation: Productivity Series https://accautomation.ca/series/productivity-1000-plc/ https://accautomation.ca/series/productivity-2000-series-plc-p2000/ BRX Do-More Series (Do-More Designer Software + Simulator) https://accautomation.ca/series/brx-do-more-plc/ Click PLC Series https://accautomation.ca/series/click-plc/ Omron CP1H Series https://accautomation.ca/series/omron-plc-cp1h-series/ Horner XL4 PLC Series https://accautomation.ca/series/horner-xl4-series/ https://accautomation.ca/series/easyplc-software-suite/ EasyPLC Software Suite is a complete PLC, HMI, and Machine Simulator Software package. See below to receive 10% off this software. This PLC learning package includes the following: Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script. HMI System – Easily create a visual human-machine interface (HMI) Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.) Machine Simulator Lite – Designed to run on Android Devices. Machine Simulator VR – Virtual Reality comes to life so you can test, train or practice your PLC programming. Purchase your copy of this learning package for less than USD 75 for a single computer install or less than USD 100 to allow different computers. Receive 10% off the investment by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/ Learn PLC programming the easy way. Invest in yourself today. Regards, Garry ACC Automation https://accautomation.ca/