Q: What is a Productivity PLC?

A: A Productivity Programmable Logic Controller (PLC) is an industrial automation system that controls and monitors industrial processes.

Q: What are the benefits of using a Productivity PLC?

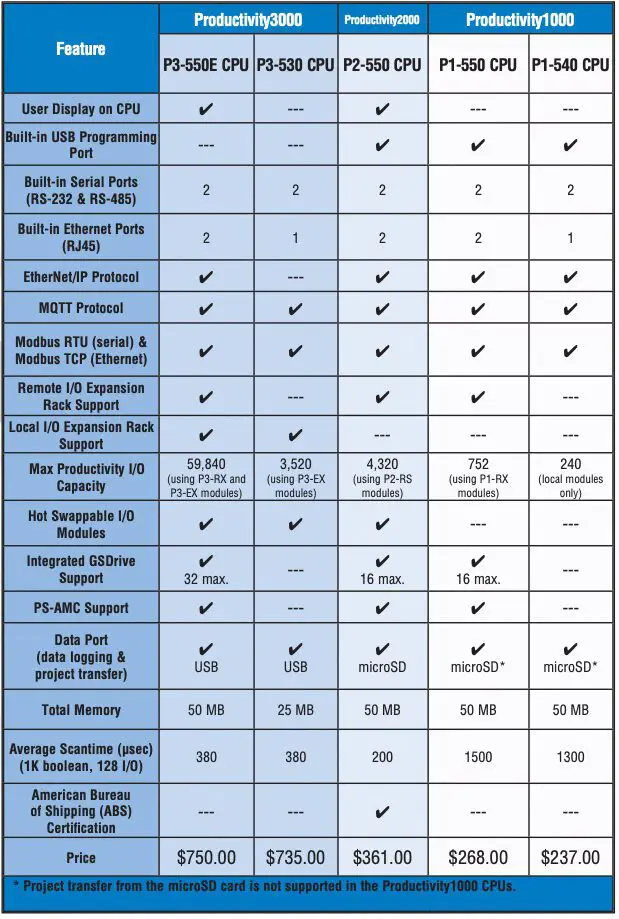

A: Productivity PLCs offer a range of benefits, including improved efficiency, increased productivity, reduced downtime, improved quality control, and reduced labor costs. This PLC has three hardware configurations; P1000, P2000, and P3000. All of these can be programmed using the same Productivity Suite Programming software. Your learning curve is dramatically reduced.

Configure a Productivity 1000

Configure a Productivity 2000

Configure a Productivity 3000

Q: What programming languages can be used with a Productivity PLC?

A: Productivity PLCs can be programmed using ladder logic (LD). Ladder logic is the most common PLC programming language.

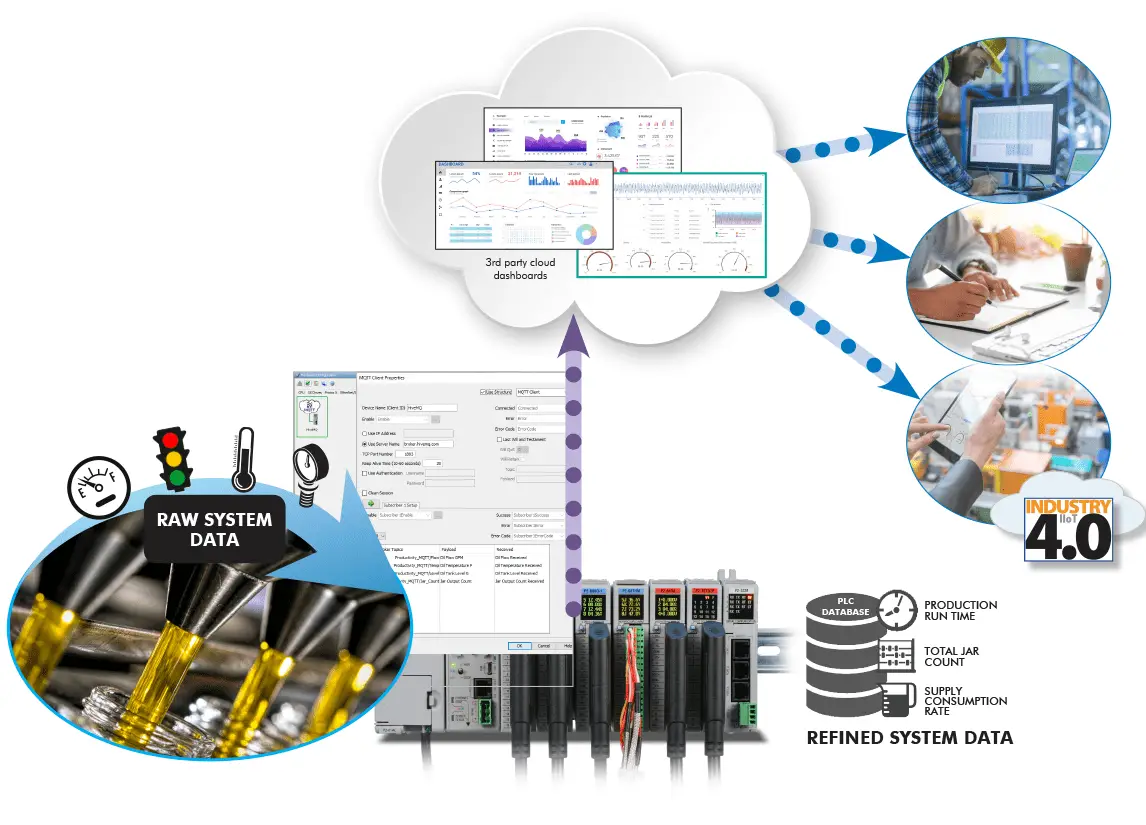

Q: What communication protocols are supported by Productivity PLCs?

A: Productivity PLCs support many communication protocols, including Modbus RTU, Modbus TCP/IP, EtherNet/IP, MQTT, ASCII, & custom protocols. The media that supports the protocols include RS-232, RS-485, Ethernet, Remote I/O, and USB (programming).

Q: Can Productivity PLCs be used in remote locations?

A: Yes, Productivity PLCs can be used in remote locations. They can be accessed remotely using various communication methods, including cellular, satellite, and radio.

Q: What types of industries are Productivity PLCs used in?

A: Productivity PLCs are used in various industries, including manufacturing, food and beverage, oil and gas, water and wastewater, etc.

Q: What is the maximum number of I/O points connected to a Productivity PLC?

A: The maximum number of I/O points connected to a Productivity PLC depends on the specific model used.

Configure a Productivity 1000

Configure a Productivity 2000

Configure a Productivity 3000

Q: How can I learn more about Productivity PLCs?

A: You can learn more about Productivity PLCs by visiting the manufacturer’s website, attending training courses, or consulting with a certified distributor or integrator.

Q: What is a Tag-Based PLC?

A: A tag-based PLC (Programmable Logic Controller) is an industrial automation system that uses a database of tags to control and monitor industrial processes. In a tag-based PLC, each input, output, and variable is assigned a unique tag or identifier, which is used to reference the data throughout the system. This allows for easy organization and management of data and simplifies the programming process.

Tags can be assigned to various data types, such as boolean, integer, float, and string. Using tags allows for more flexible programming, as changes to the system can be made by modifying the tag database instead of rewriting the entire program.

Tag-based PLCs also offer advanced features such as data logging, trending, and alarm management. Data logging allows the system to record and store data over time, which can be used for analysis and troubleshooting. Trending allows for the visualization of data over time, which can help identify patterns and anomalies. Alarm management allows the system to monitor for abnormal conditions and generate alerts when certain thresholds are exceeded.

Tag-based PLCs are commonly used in various industries, such as manufacturing, food and beverage, oil and gas, and water and wastewater. They are often used in applications that require complex control and monitoring, such as process control, motion control, and machine automation.

Q: What kind of support is available for Productivity PLCs?

A: Productivity PLCs come with free technical support and online resources, including user manuals, programming software, and a knowledge base.

Productivity 1000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Programming Software (Free Download Link)

This software contains all the instruction sets and help files for the Productivity Series.

Productivity 2000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Overview (Features of the fully functional free software package for the Productivity Family of PLC (PAC) controllers)

Productivity Suite Programming Software (Free Download Link)

This software contains instructions and helps files for the Productivity Series.