Q: What is the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC is a programmable logic controller designed for industrial automation and IoT applications. It combines the flexibility and ease of use of the Arduino platform with the robustness and reliability of a PLC.

Q: What is the difference between regular and IoT PLC?

A: A regular PLC is a standalone device that controls a specific process or machine. An IoT PLC is designed to communicate with other devices and systems over the internet. This allows it to collect and share data and to be controlled remotely.

Q: What are some of the key features of the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC features an ARM Cortex-M7 microcontroller, Ethernet connectivity, Wi-Fi connectivity, Bluetooth Low Energy connectivity, and a range of input and output ports for connecting to sensors and actuators. It also has various software tools and libraries for programming and configuring the device.

Q: What programming languages can program the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC can be used with a standard computer and the Arduino IDE, available for free download from the Arduino website. It can also use the free Arduino PLC IDE software. The license is already included in the OPTA PLC. Choose any of the five programming languages defined by the IEC 61131-3 standard (Ladder, Functional Block Diagram, Structured Text, Sequential Function Chart, or Instruction List) and quickly code PLC applications.

Q: Can the Arduino Opta IoT PLC be used for industrial automation applications?

A: The Arduino Opta IoT PLC is designed for industrial automation applications and can be used in various settings, including manufacturing, energy, agriculture, and more.

Q: What sensors and actuators can be connected to the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC supports a range of sensors and actuators, including temperature sensors, pressure sensors, light sensors, motors, and valves. This is accomplished with the digital or analog 0-10 VDC and the relay outputs.

Q: What kind of data can be collected and analyzed using the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC can collect a wide range of data, including temperature, humidity, pressure, light, sound, and motion. This data can be analyzed to gain insights into process performance, detect anomalies, and optimize operations.

Q: Can the Arduino Opta IoT PLC be integrated with other IoT devices and systems?

A: Yes, the Arduino Opta IoT PLC can be integrated with other IoT devices and systems using a range of protocols and interfaces, including MQTT, Modbus RTU, Modbus TCP, and more.

Q: Where can I learn more about the Arduino Opta IoT PLC?

A: You can learn more about the Arduino Opta IoT PLC by visiting the Arduino website or consulting online resources and forums for Arduino and PLC programming. See the bottom of this FAQ for additional links.

Q: What industrial automation tasks can the Arduino Opta IoT PLC be used for?

A: The Arduino Opta IoT PLC can be used for various industrial automation tasks, including process control, machine control, monitoring and logging of production data, environmental monitoring, and more.

Q: What communication protocols does the Arduino Opta IoT PLC support?

A: The Arduino Opta IoT PLC supports a range of communication media types, including Ethernet (RJ45), Wi-Fi, Serial (RS485), and Serial (USB). The communication protocols that you can implement include Modbus, MQTT, etc.

Q: Can the Arduino Opta IoT PLC be used for remote monitoring and control?

A: The Arduino Opta IoT PLC can remotely monitor and control industrial processes and machines. It can be connected to the internet and accessed from anywhere worldwide using a web browser or a mobile app.

Q: Does the Arduino Opta IoT PLC come with pre-built software libraries?

A: The Arduino Opta IoT PLC can be programmed using the Arduino IDE. This can then take advantage of the various software libraries for everyday industrial automation tasks, such as data logging, PID control, and Modbus communication. The Arduino PLC IDE has various software libraries built into this software. This will help you with programming this industrial controller.

Q: Can the Arduino Opta IoT PLC be customized to meet specific industrial automation requirements?

A: The Arduino Opta IoT PLC is highly customizable and can be programmed to meet specific industrial automation requirements using the Arduino IDE and other programming tools.

Q: Does the Arduino Opta IoT PLC require any special hardware or software to be used?

A: No, the Arduino Opta IoT PLC can be used with a standard computer and the Arduino IDE, available for free download from the Arduino website. It can also use the free Arduino PLC IDE software. The license is already included in the OPTA PLC. Choose any of the five programming languages defined by the IEC 61131-3 standard (Ladder, Functional Block Diagram, Structured Text, Sequential Function Chart, or Instruction List) and quickly code PLC applications.

Q: What security features does the Arduino Opta IoT PLC have?

A: The Arduino Opta IoT PLC has various built-in security features, including secure boot, hardware encryption, and secure communication protocols. It also supports secure remote access and user authentication.

Q: Can the Arduino Opta IoT PLC be used in hazardous environments?

A: The Arduino Opta IoT PLC is not designed for use in hazardous environments, such as explosive atmospheres or high radiation areas. It should only be used in environments that meet its specified operating conditions.

Q: What power supply is required for the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC requires a 12 to 24V DC power supply to operate the inputs and outputs of the programmable logic relay. If you want to program only, a USB C cable can power the CPU to program.

Q: Can the Arduino Opta IoT PLC be used in standalone and networked configurations?

A: The Arduino Opta IoT PLC can be used in standalone and networked configurations, depending on the application requirements.

Q: What documentation and support are available for the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC has detailed documentation and tutorials, including getting-started guides, technical specifications, and programming examples. Arduino also offers online support through forums and a knowledge base.

Q: Can the Arduino Opta IoT PLC be used in commercial and non-commercial applications?

A: Yes, the Arduino Opta IoT PLC can be used in commercial and non-commercial applications, subject to the terms of the Arduino license agreement.

Q: What software tools and languages can you program the Arduino Opta IoT PLC?

A: The Arduino Opta IoT PLC can be programmed using the Arduino IDE, which supports C++. Arduino PLC IDE can also program the OPTA PLC. Choose any of the five programming languages defined by the IEC 61131-3 standard (Ladder, Functional Block Diagram, Structured Text, Sequential Function Chart, or Instruction List). Arduino PLC IDE also includes support for C++ sketches.

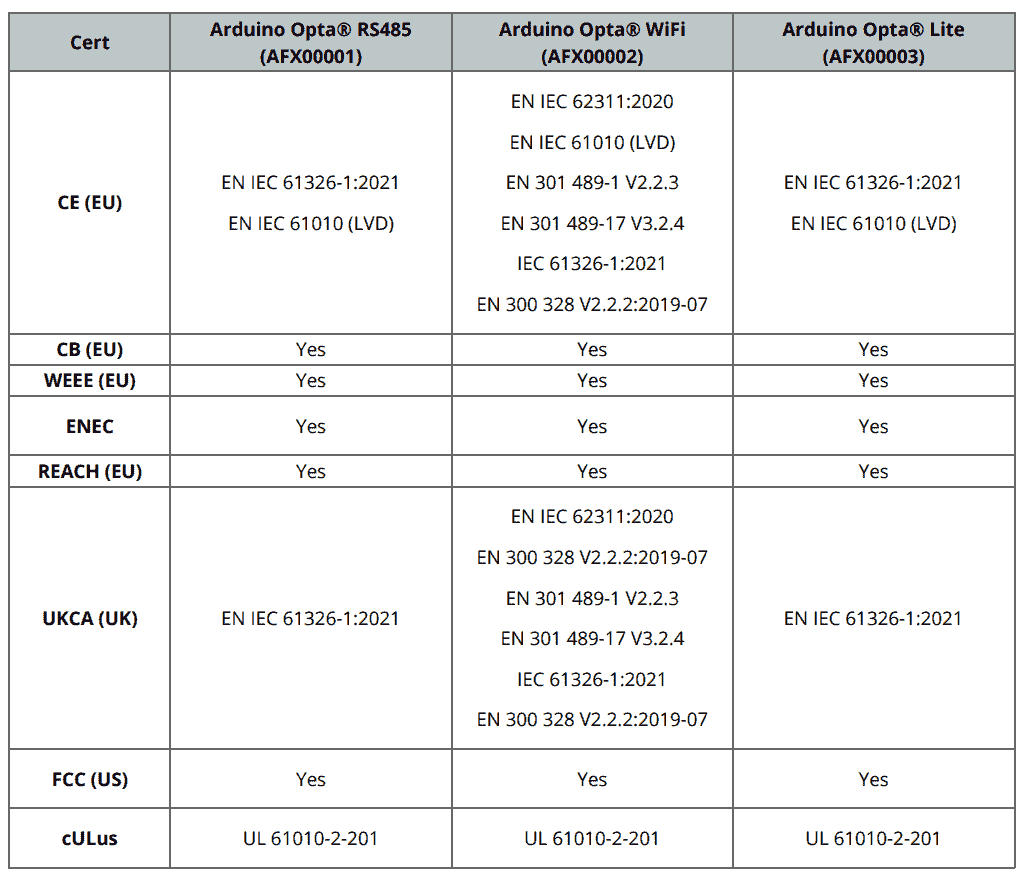

Q: What testing and certification standards does the Arduino Opta IoT PLC comply with?

A: The Arduino Opta IoT PLC complies with a range of testing and certification standards, including CE, FCC, and RoHS.

Q: How does the Arduino Opta IoT PLC compare to other PLCs and IoT devices on the market?

A: The Arduino Opta IoT PLC offers a unique combination of flexibility, ease of use, and industrial-grade reliability, which sets it apart from other PLCs and IoT devices on the market. Its support for a wide range of communication protocols and its customizable programming interface make it a versatile tool for industrial automation and IoT applications.

Q: Do I have to purchase a license to program ladder logic with my Opta PLC?

A: The Arduino Opta PLC has a license to use the Arduino PLC IDE. This will allow you to program in the standard 5 programming languages and C++ (Sketch).

Q: How are the discrete inputs wired for the Opta PLC?

A: The Opta IoT PLC datasheet specifies that the supply voltage should be 12 to 24VDC. The inputs will turn on when the voltage reaches 6.6 VDC and off when it drops to 4.46 VDC. The Opta’s discrete inputs (on/off) will switch to +DC voltage. Since the controller input common is at 0 VDC, this is considered a sinking input. You can refer to a post that covers the wiring of NPN and PNP 3-wire sensors for more information. 3-wire sensors should have PNP outputs. The Opta PLC input will replace the load shown in the sensor wiring diagram.

Q: How does the regular Arduino IDE software upload code to the Opta?

A: Using the regular Arduino IDE software, you must activate bootloader mode to upload code to the Opta. Connect your Arduino Opta IoT PLC to your computer via a USB ‘C’ cable that can handle both power and data. Simply double-tap the reset button on the Arduino OPTA PLC to activate bootloader mode, indicated by the CPU’s pulsing light. You can now proceed to download your program code.

Helpful external links to tips and references:

Aduiono Opta IoT PLC Series

Arduino Opta PLC – IoT and Industry 4.0 Enabler

Finder OPTA 8A Series – Tutorials

Datasheet

Quickstart Sheet

Arduino Opta Hardware

Arduino PLC IDE

Arduino Software Download Page

(Arduino IDE, PLC IDE, PLC IDE Tools)