Takt time is the beat of manufacturing. It is the rhythm of the company for making products or delivering services. Do you know what yours is? Let’s look at takt time and determine how to use it to our advantage.

What is Takt Time? (Discover Takt Time)

This is a German word taken from beats in music and used in lean manufacturing. Takt time is calculated by the total available Time divided by customer demand. This must be greater than our ability to produce a product, or we would let our customers down.

Takt Time = Total Available Time / Customer Demand

Total Available Time:

This is the total available Time for work to be performed. Lunch breaks and daily meeting times are removed from this total unless relief constantly covers them.

Customer Demand:

This is the average rate at which customers purchase products or services. It is expressed in the same time frame as Total Available Time. You can also look at projected purchases from the customer.

Example:

Total Available Time (Day):

8 hour shift x 60 = 480 minutes

480 minutes – (2*10 minute breaks) – (20 minute lunch) = 440 minutes

Customer Demand (Day):

500 units / 5 days = 100 units a day

Takt Time (Product Unit):

Total Available Time / Customer Demand

440 minutes / 100 units a day = 4.4 minutes or 264 seconds

Each product unit must be produced within 4.4 minutes.

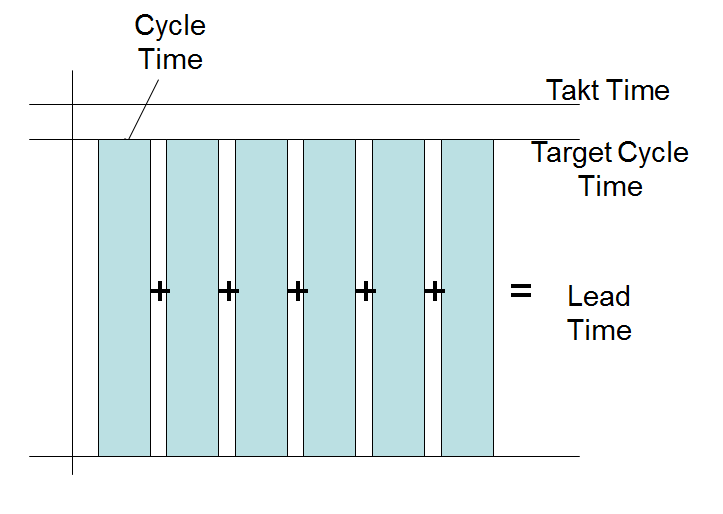

Takt Time – Pace the Customer Requires Product

Takt time is the pace the customer requires the product. This differs from Lead Time, the total production time from product start to finish. The other definitions that get confused are Cycle Time and Target Cycle Time. Cycle Time is the Time the process cycles. The Target Cycle Time is the pace we will produce to meet customer demand. Keep in mind all of these items when looking at satisfying customer demand.

Ability to Meet Customer Demand

Takt time is just a value showing your ability to meet customer demand. Material or the lack of it behind each machine is the indication within manufacturing that will show you your current situation. Stock will buffer the unevenness of work and breaks in the manufacturing process. The goal is to synchronize the flow from the first process to the last.

If customer demand exceeds the ability to produce the product or service, you will find that stock will run out.

If customer demand is less than the ability to produce the product or service, you will find an increase in stock.

A bottleneck is a point of congestion in a system. Work arrives quicker than what can be handled. On the manufacturing floor, you can notice bottlenecks by the amount of material behind machines. It looks like the neck of a bottle which limits the ability to have liquid pass through.

Bottleneck operations are those operations where the machine cycle > Takt Time.

The goal is to eliminate the bottlenecks by looking at our ability to handle customer demand through measures like Takt Time. This does not have to be a challenging task. Through PLCs and data collection, we can monitor all of the different times discussed and ensure we satisfy customer demand.

The goal is to eliminate the bottlenecks by looking at our ability to handle customer demand through measures like Takt Time. This does not have to be a challenging task. Through PLCs and data collection, we can monitor all of the different times discussed and ensure we satisfy customer demand.

Watch on YouTube: Who Else Wants To Discover Takt Time?

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.