Digital Counter / Timer / Tachometer (CTT Series)

The CTT series from Automation Direct are multi-function digital units. They incorporate a multi-function digital counter, timer and tachometer all within the same unit. This means that you have fewer stock items and the learning curve is minimized. The CCT series are easily configured as a digital counter, timer, combination timer-counter or tachometer.

The two colour LCD display shows present values, setting values and menu parameters during setup. Process control parameters are easily set using the externally accessible DIP switches or the lockable keypad. We will be looking at this versatile multi-fictional device. Let’s get started.

CTT Series – Counter / Timer / Tachometer

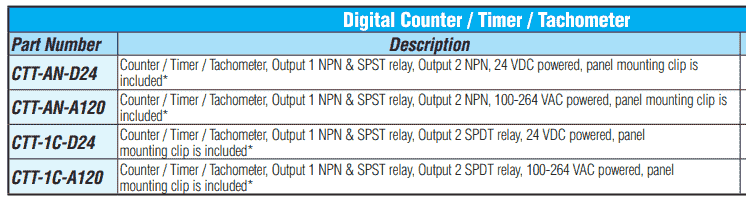

Ordering Information:

Every unit is a counter, timer or tachometer. You select the mode that is required for your application. All units come with a NPN and SPST relay contacts on CTT output 1. Output 2 on the CTT can be ordered as a NPN or SPST relay contact.

CTT-AN = Output 2 NPN

CTT-1C = Output 2 SPST relay contact

The supply voltage can be either 24VDC (-D24) or 100-264VAC (-A120). This gives us a combination of 4 different units to choose.

Watch on YouTube : CTT Counter Timer Tachometer – Un-boxing the CTT

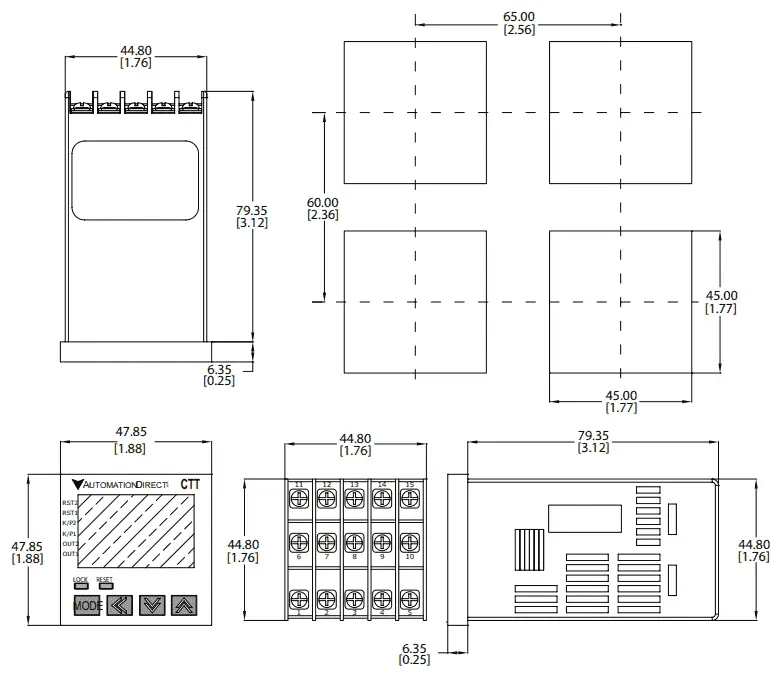

Dimensions

mm [inches]

1/16 DIN size (48 x 48 mm)

Wiring

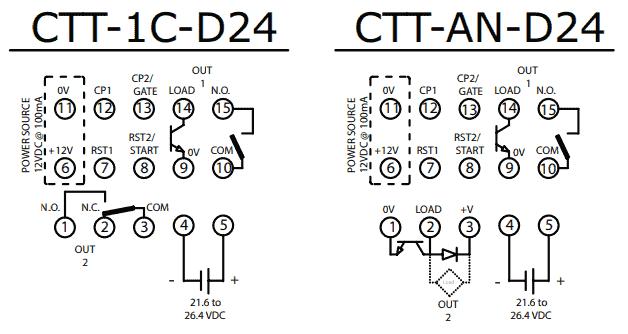

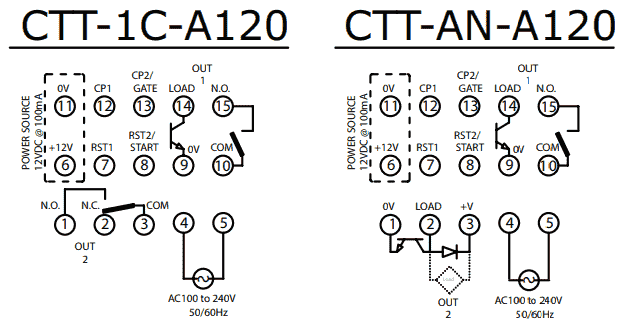

Here are the wiring diagrams for all four units.

The 24DC power supply units side by side. Notice that the only difference is output 2. One is NPN and the other is SPST relay.

The AC power supply can be anywhere from 100 to 240 VAC. Note that output 2 is the same options as the DC version.

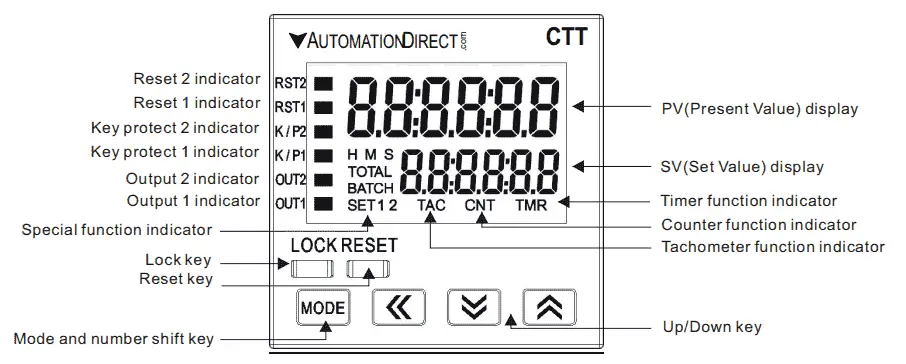

Display, Indicators, and Keys

Reset 2 / 1 indicator – Light on when reset signal is detected

Key protect 2 / 1 indicator – Light on when key-protected mode is enabled

Output 2 / 1 indicator – Light on when output is executing

H M S – Hour, minute, second unit of timer displayed in Timer function

TOTAL – “Total Counting Mode” in Counter function

BATCH – “Batch Counting Mode” in Counter

SET 1 2 – SV1, SV2 display – Set Value

TAC – Light on in Tachometer function

CNT – Light on in the Counter function

TMR – Light on in Timer function

Note: See the video below for the operation of the front panel.

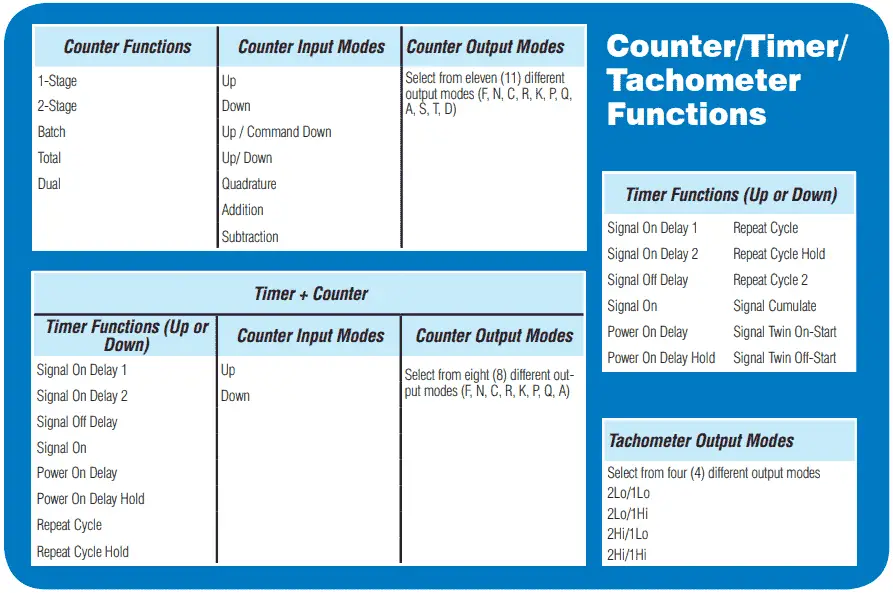

CTT Functions

CTT Series Programming

Programming of the CTT Series can be done with DIP switches or the lockable keypad on the unit. You can choose the way your unit will function by looking at the timing chart diagrams for each of the different modes. The following two posts will explain the timing chart diagrams and how to read them.

The Secret of Using Timers – Video

The Secret of Using Counters – Video

Here is an example of the timing charts for the CTT Series.

Watch on YouTube: CTT Counter Timer Tachometer – Powering the Unit

Summary of CTT features

– Can operate as a digital counter, timer, combination timer + counter, or tachometer

– Accepts voltage and non-voltage inputs from a wide variety of NPN, PNP, or dry contact sensors

– Selectable counting speeds from 1 to 10,000 cycles per second

– Multiple transistor and relay outputs can operate as momentary or maintained

– Double-line, 6-digit, 2-color LCD display

– Easy configuration with externally accessible DIP switches or the lockable keypad

– Display decimal point selection

– Available in 100-240VAC and 24VDC powered models

– UL508 listed (E311366), cULus, CE marked

Counter, Timer, Tachometer – CTT Series from Automation Direct

Shop Multi-Function Digital Counter / Timer / Tachometer

CTT Overview

https://cdn.automationdirect.com/static/specs/cttcountertimertachoverview.pdf

CTT Quick Start Guide

https://cdn.automationdirect.com/static/manuals/cttqsg/cttseries_qsg.pdf

Digital CTT Manual

https://cdn.automationdirect.com/static/manuals/digitalctt/digitalctt.html

Rhino Power Supply

https://www.automationdirect.com/adc/Overview/Catalog/Power_Products_(Electrical)/DC_Power_Supplies

https://cdn.automationdirect.com/static/specs/pslpowersupplies.pdf

Next time we will look at the programming of the timer mode in the CTT.

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.