Turn a capacitive proximity sensor into a level sensor. This is ideal for tanks and vessels you cannot drill through the side for mounting.

Wrap the bare wire around the sensing head and extend it to the length you need to detect. Insulate the wire using electrical tape, but leave the end exposed. This acts as an antenna. Anything touching the end will now be seen. I have used 14 and 12 AWG wires, depending on the application.

Some quick information about capacitive proximity sensors.

A capacitor is defined as two electrically charged plates separated by a dielectric. In the case of a capacitive proximity sensor, the dielectric is the material you are trying to detect. As the material moves closer to the electrostatic field of the sensor, oscillation begins. It will get past a threshold and trigger the output to switch.

Some common dielectric constants for material:

Glass – 5

Wood – 2.7

Paper – 2.3

Air, Vacuum – 1

Water – 80

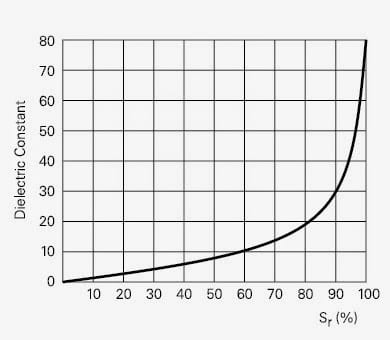

Once you know the dielectric constant, you can determine the sensing range (Sr) by a chart that usually comes with the sensor or in the manufactures manual.

Example: Water is 80, so the sensing range is 100%

I generally try the sensor to determine if it suits the application.

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.