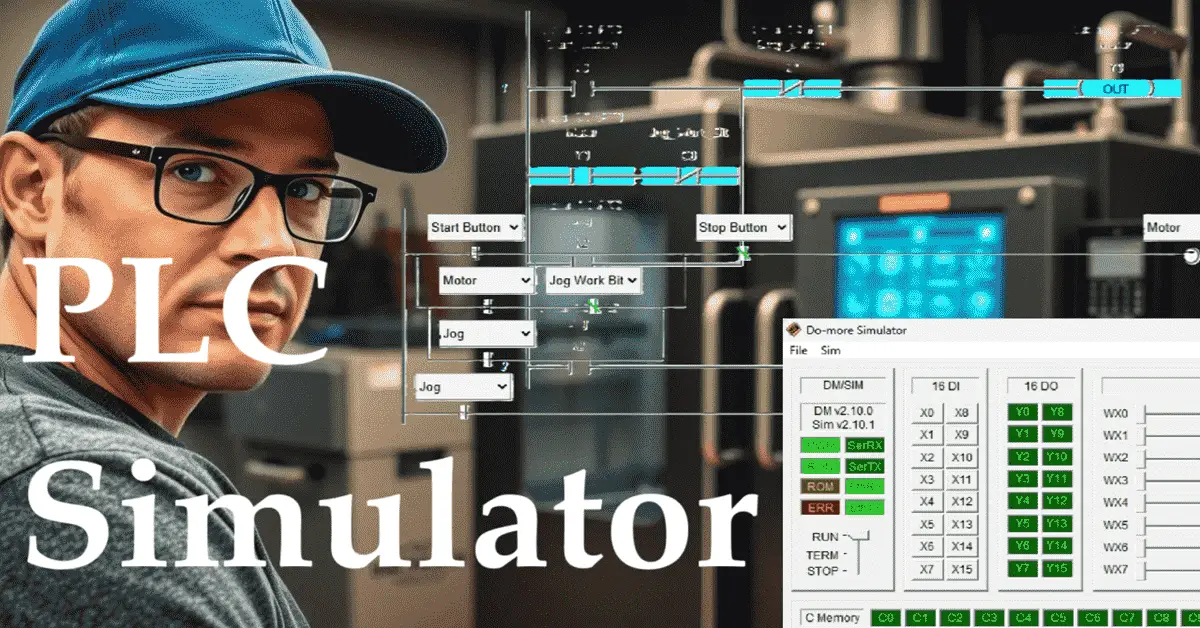

Why Every Beginner Needs a PLC Simulator Now!

Why Every Beginner Needs a PLC Simulator Now! Are you tired of feeling left behind in the industrial automation industry? As a beginner, it can be overwhelming to keep up with the latest technologies and trends. That’s why PLC simulation is more crucial than ever! We’ll explore the importance of PLC simulation and why it’s … Read more