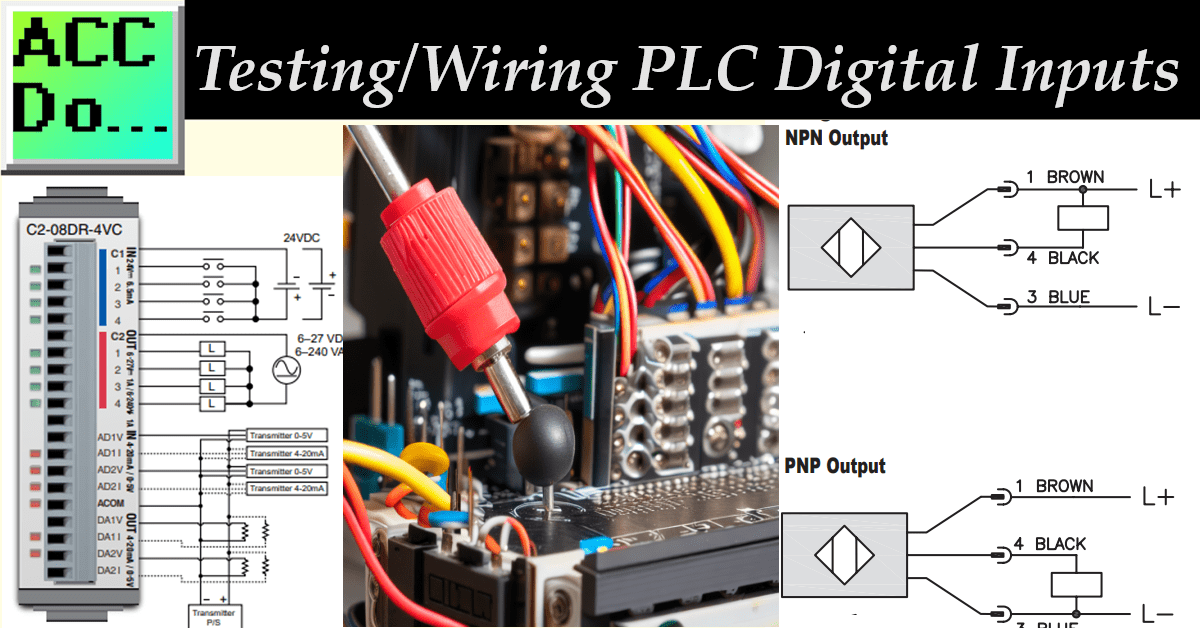

Testing and Wiring PLC Digital Inputs

To ensure the proper functioning of any PLC digital input, it is crucial to correctly test and wire the discrete inputs. By understanding the testing process and providing accurate wiring, we can guarantee the optimal performance of our PLC hardware. Testing the inputs allows us to verify that they function as intended and that our … Read more