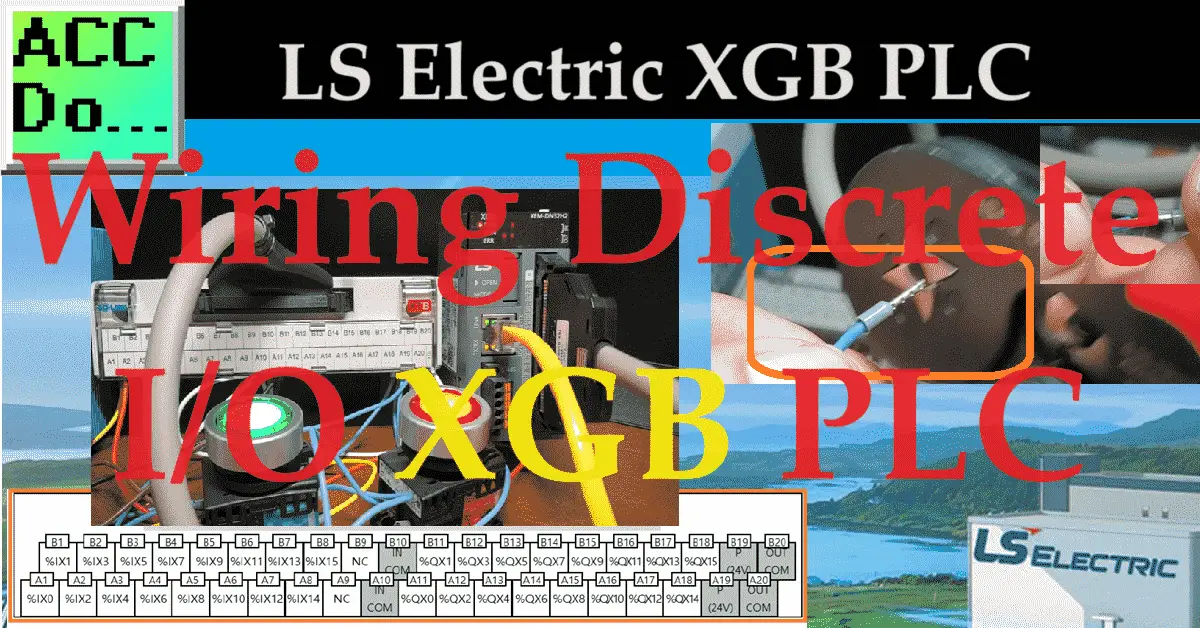

Wiring Discrete I/O to an XGB PLC

We will be wiring discrete inputs and outputs to an XGB PLC. This will be a lighted pushbutton start and stop. In industrial automation, Programmable Logic Controllers (PLCs) are crucial in controlling various machines and processes. One of the most widely used PLCs is the LS Electric XGB series, which is known for its reliability … Read more