PLC programming involves both direct and indirect addressing. Direct address programming involves writing each ladder logic rung to do the operation required. We often forget about using powerful indirect addressing to solve our logic.

Indirect Addressing – Faster PLC Program

The below-animated picture will show a simple example of using indirect addressing. This will use the MOVE instruction and transfer a word indirectly to output word V100. V[V0] means that the value in V0 will point to the V memory to get the value to move. You can think of this as a pointer for the memory location to move.

Of course, we need to monitor V0. We need to ensure that V0 is always from 1 to 6. Our values are in sequence from V1 to V6.

Program Example – Faster PLC Program

Let’s look at a program sample using the Do-more Designer Software. We will set up the sequence similar to the animation above but expand the program.

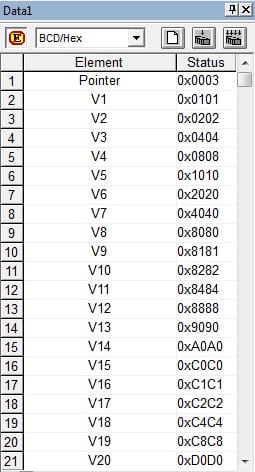

Like above, we will set up the pointer at V0 and the output at V100 memory locations. V1 to V37 will hold our output data sequence. We want to set these outputs on each event and time frame. You can see some of the registers and the corresponding values. These are selected as a hexadecimal values. The following link will provide a review of the numbering systems in the PLC. (WHAT EVERYBODY OUGHT TO KNOW ABOUT PLC (PROGRAMMABLE LOGIC CONTROLLER) NUMBERING SYSTEMS)

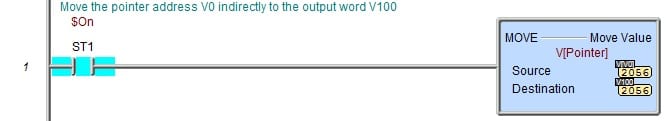

This is the logic to set up the move instruction. The source is V[V0], meaning the pointer is V0 in this memory area. The destination will be V100.

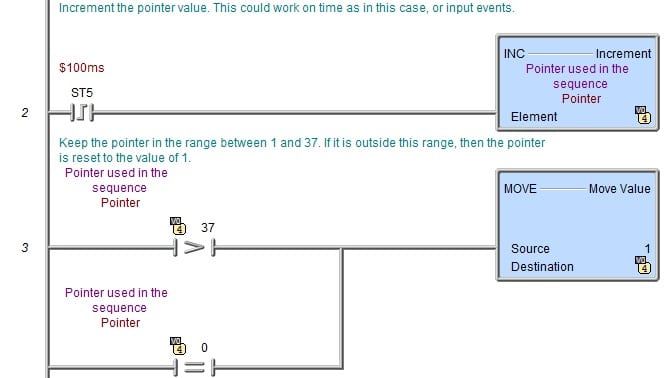

An internal timing bit ST5($100ms) is used to increment the pointer V0. It’s then compared to ensure that it is between 1 and 37.

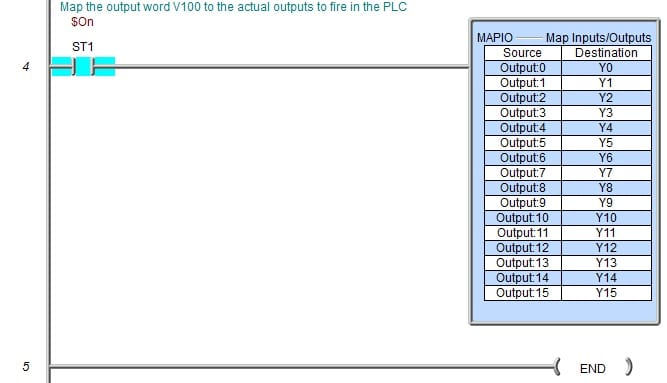

Finally, This could also be done by an event or series of events. The output word is then transferred to the physical outputs. This is done by using MAPIO instruction. Each bit can be set independently.

This example uses indirect addressing to program a sequence based on time. We could just as quickly use indirect addressing to compare inputs to a table and set the outputs accordingly. You can see how this method can significantly reduce the time to develop your program. This holds especially true if the sequence needs to be changed. It would be just a matter of changing data values in the table.

The following are separate posts that use indirect addressing:

Building a PLC Program You Can Be Proud Of – Part 1

This uses the control of an intersection traffic light to demonstrate direct versus indirect addressing.

Building a PLC Program That You Can Be Proud Of – Part 2

A sample program to control valves. This uses indirect addressing for the inputs as well as the outputs.

Now You Can Have Robust Data Logging for Free – Part 1

Using indirect addressing, this sample program will log information in the PLC to be retrieved later.

Indirect addressing is a powerful method of programming to simplify and program faster than you ever thought possible. You can even use indirect addressing in the PLC to scale a non-linear analog input signal. Let me know your thoughts on using indirect addressing. What can you come up with?

Watch on YouTube: Here is a Method That is Helping PLC Programmers to Program Faster

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.