- Automation Direct – Do-More – H2-DM1E PLC (Ethernet Modbus TCP)

- Do-more Designer 1.3 (Simulator instead of PLC mentioned above)

- Windows-based computer running IIS

- Visual Basic 6

The following steps will be explained in detail and sample programming.

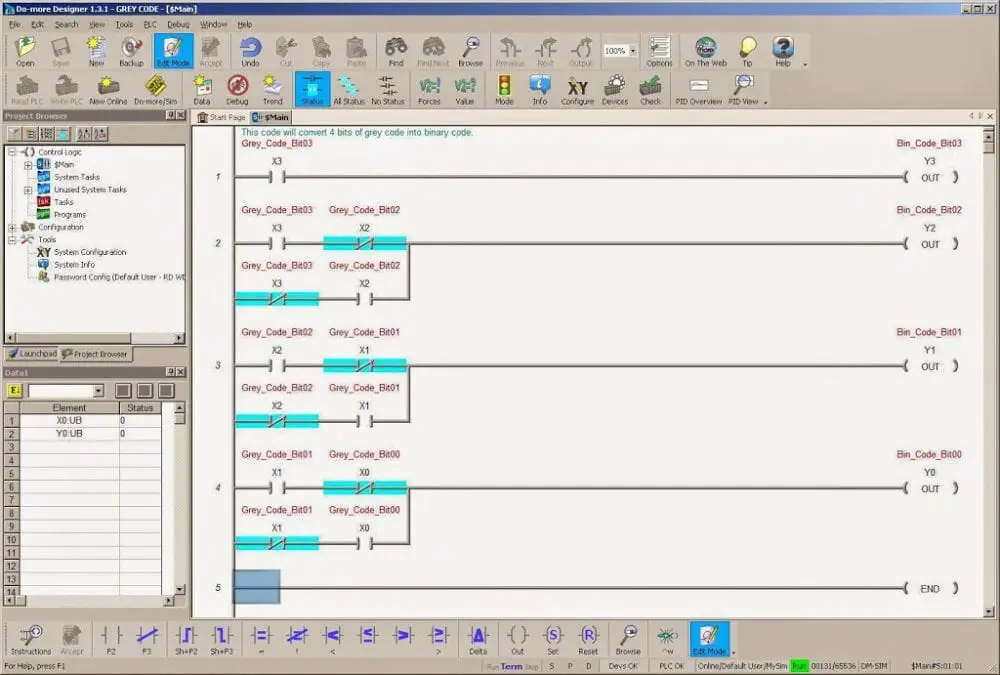

PLC program

The programmable logic controller PLC will log the data in the PLC memory using indirect addressing for the data log. Information will be collected based on shifts.

We will use the following shift schedule. Midnight, Afternoon, and Days for the weekday and have two-weekend shifts. Each shift will show the amount of product made, utilization of the machine, and rate of product produced.

Also, we will log a minute-by-minute account of the machine. This will log the amount of product made and the rate at which it is made. We can then graph the machine’s performance to determine if it is running correctly.

Data Collection

Visual Basic 6 will be used to log the data into a database. The information will be collected using Modbus TCP communication to the Do-More PLC and the Simulator of the Do-more Designer. This will use an Ethernet communication cable to the PLC. The program will read the indirect address pointers in the PLC. The program will then reset the indirect address pointers. It will then read the information collected and store it in an Access Database.

Data Distribution

We will set up a web server (IIS). This will allow the access database containing the information from the PLC to be available to all of the computers on the local network. (Intranet)

We will use Active Server Pages (ASP) and HTML to create programs to access this database information. Web browsers will call our ASP and HTML programs to display the information on the device. This will be universal when we look at it with computers, tablets, and phones.

Advanced-Data Distribution

Using Raphael and SVG programming, we will graph using line graphs. We will also see how we can use dials to create dashboards on our web server.

This may sound like a lot of work, but it is not. What we are doing is breaking down the fundamentals to display information. Using a robust logging system from the PLC ensures reliability and confidence in the data collected. Once the basic principles are applied, your system can expand rapidly.

Are you ready?

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.