The Iron Heart of Your Network: The Industrial Ethernet Switch. Unboxing and Mastering the STRIDE Industrial Ethernet Switch

Did you know that over 40% of industrial network failures are attributed not to software bugs or hackers, but to simple environmental stress?

Imagine a scorching summer day on a factory floor, ambient temperatures rising above 100°F, or a remote utility station freezing in the dead of winter. In these moments, standard office-grade equipment doesn’t just falter; it melts, cracks, and quits. When the network goes down, production stops. And when production stops, money burns. If you are relying on the same plastic switch used in a climate-controlled server room to run your oil rig, manufacturing plant, or outdoor kiosk, you are sitting on a ticking time bomb. Today, we aren’t just looking at a switch; we are looking at insurance for your uptime.

Industrial Ethernet

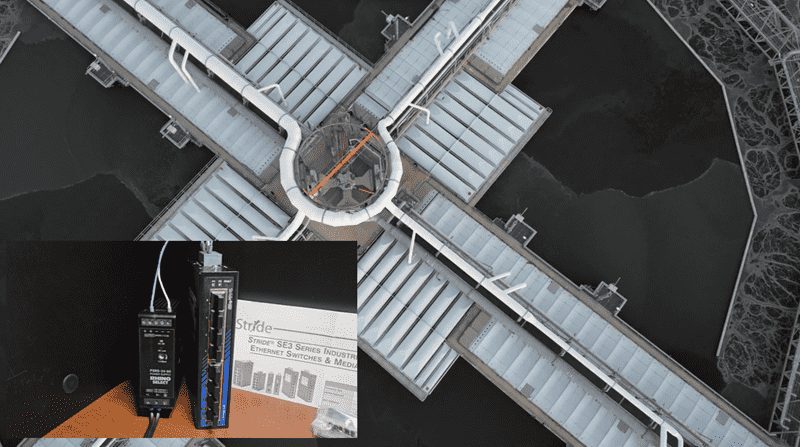

Welcome to the world of Industrial Ethernet. Today, we are focusing on a piece of hardware that acts as the central nervous system for rugged operations: the STRIDE Industrial Unmanaged Ethernet Switch.

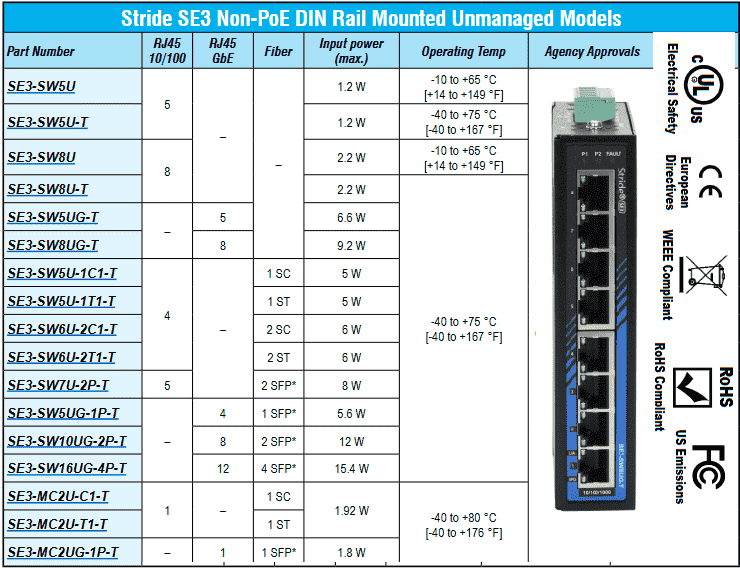

Specifically, we are looking at the 8-port Gigabit model. Why does this matter? Because in the age of IIoT (Industrial Internet of Things), data density is increasing. You aren’t just sending simple “on/off” signals anymore; you’re streaming video from vision systems, pulling massive logic files, and monitoring real-time analytics. You need bandwidth, and you need speed. This STRIDE switch offers (8) Ethernet Gigabit (RJ45) ports, encased in a housing that looks like it could survive a tank tread. It is built for the extremes, rated for a staggering -40 to +75°C. This is where IT meets the grit of OT (Operational Technology).

Problem/Challenge

Let’s be honest about the environments we work in. Industrial settings are the enemies of electronics.

First, there is Temperature. A standard switch is happy at 70°F. But put that switch in a NEMA enclosure outside in North Dakota in January, or next to a blast furnace in Alabama, and the internal components will expand, contract, and eventually desolder themselves.

Second, there is Vibration. Large motors, punch presses, and forklifts create constant tremors. Standard RJ45 jacks and plastic clips vibrate loose, causing intermittent packet loss—the kind of “ghost” problems that take hours to troubleshoot.

Third, there is Electrical Noise and Dust. A typical office environment is clean. A factory floor is a storm of electromagnetic interference (EMI) and conductive dust. If your switch isn’t built with IP30 protection and shielded components, you aren’t building a network; you’re building a failure point. The challenge isn’t just “connecting devices”; it’s keeping them connected when the world around them is trying to shake, bake, and freeze them to death.

Exploration/Development: Unboxing & Installation

This is where the STRIDE shines. Let’s get this beauty on the bench and see what makes it tick.

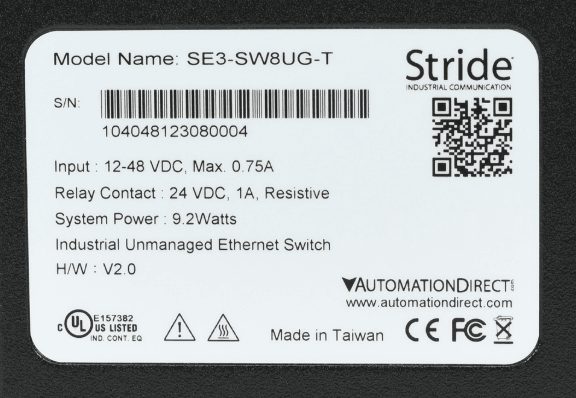

The Unboxing. As we crack open the box, the first thing you notice is the weight. This isn’t flimsy plastic; it’s a robust metal housing. It feels cold, solid, and substantial. Included in the box, you’ll find the switch itself, a terminal block for power, and your mounting hardware.

The Form Factor: It’s compact, designed for a 35mm DIN rail mount. This is standard for control panels, allowing it to snap right in alongside your PLCs and power supplies. It also supports panel mounting if you’re working in a tight cabinet without rails. The IP30 rating means it’s protected against solid objects larger than 2.5mm—perfect for keeping out tools and stray wires in a busy panel.

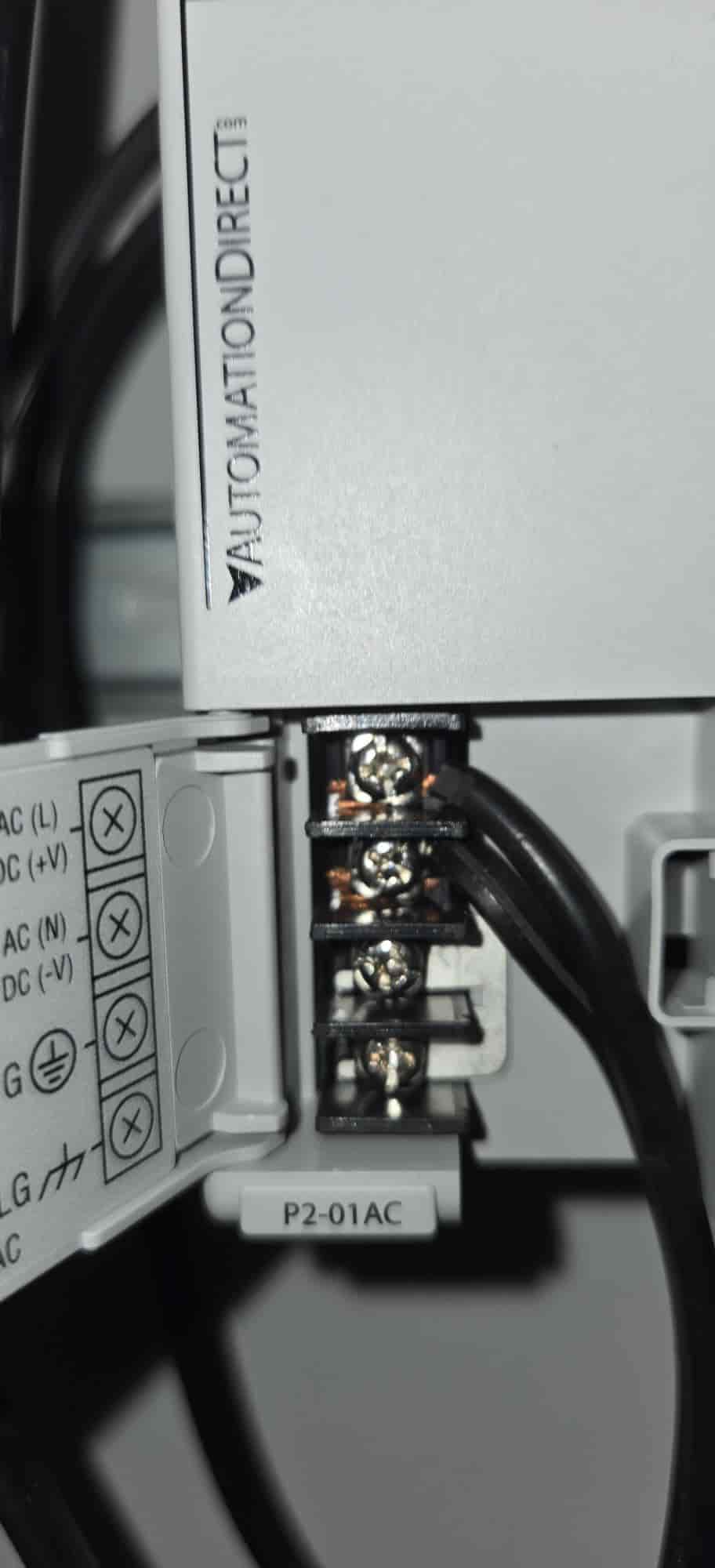

Wiring: Doing it Right with Ferrules. Now, let’s give power to this beast. This is a critical step that many amateurs get wrong.

The STRIDE switch uses a removable terminal block for its power inputs. You are likely using stranded wire for your DC power distribution because it’s flexible and better handles vibration than solid-core wire. However, never insert bare stranded wire directly into a screw terminal.

Why? As you tighten the screw, the strands splay out. This leads to a poor connection, or worse, a single stray strand touching the chassis or a neighboring terminal, causing a short circuit.

The Solution: Use ferrules.

Strip your wire, slide on a ferrule, and crimp it down. Now you have a solid metal contact point that inserts cleanly into the terminal block. It ensures 100% surface area contact and vibration resistance. Wiring with ferrules isn’t just “best practice”; in the industrial world, it’s the mark of a professional.

Initial Powering Up Once your power wires (usually 12-48 VDC) are secured in the terminal block, plug it into the switch. Flip your breaker or power supply on.

You should see the Power LED light up solid green. This indicates the internal logic is receiving juice. You’ll also see LEDs for each of the 8 Gigabit ports, which will flicker with activity once you patch in your Ethernet cables.

Troubleshooting the “Fault” Light

Here is a scenario that trips up even seasoned technicians.

You’ve wired up the power. You turn it on. The switch works, but there is an ominous red light: The Fault LED is on.

Panic sets in. Is the unit dead? Did you fry it?

The Reality: The STRIDE switch is designed for mission-critical redundancy. It has inputs for Power Supply 1 (P1) and Power Supply 2 (P2). In a perfect world, you would have two separate DC power sources wired in so that if one dies, the other takes over instantly.

However, many of us are just wiring a single power supply for a simple application. The switch detects voltage at P1, but sees 0V at P2. It thinks a power supply has failed, so it triggers the alarm and lights the Fault LED.

The Fix: If you are intentionally only using one power source, you need to “trick” the switch.

Take two small jumper wires.

Jump the positive terminal of P1 to the positive terminal of P2.

Jump the negative terminal of P1 to the negative terminal of P2.

By jumping these out, the switch sees voltage at both inputs. The logic is satisfied, the red Fault light turns off, and the relay output closes. You now have a “healthy” status. This is a pro-tip that saves you from staring at a red warning light for the next ten years.

Real-World Application

Consider a water treatment plant in Minnesota. Last winter, temperatures hit -30°F. Their previous commercial-grade switches froze; the capacitors failed, and the telemetry data for tank levels went dark. They had to send a technician out in a blizzard to manually check gauges.

They swapped to this STRIDE unmanaged switch. Because of its -40°C rating and metal heat-sink properties, it shrugged off the cold. The Gigabit speeds handled the high-res security camera feeds monitoring the perimeter, and the redundant power inputs (wired correctly this time!) ensured the network stayed live even when a DIN-rail power supply hiccuped. That is the difference between a crisis and a normal Tuesday.

The STRIDE 8-port Industrial Ethernet Switch is more than just a cable junction box. It is a hardened warrior built for the front lines of industry. From the metal housing and IP30 rating to the wide -40 to +75°C temperature range, it is designed to survive where others fail.

By taking the time to install it correctly—using ferrules on your stranded wires and jumpering the redundant power inputs to clear faults—you ensure a clean, professional, and reliable installation. Whether you are running automation in a hot automotive plant or data logging in a freezing wind farm, this switch ensures your data keeps flowing.

Have you ever had a network switch fail due to heat or dust? What was the cost of that downtime?

Drop a comment below—I’d love to hear your “horror stories” from the field and how you solved them. If you found this unboxing and wiring guide helpful, make sure to check out our other videos on Industrial Control Panels and proper grounding techniques.

Stay wired, stay safe, and keep those packets moving!

Ready to transform your approach to industrial automation? Discover how the Machines Simulator can revolutionize your training, development, and manufacturing processes. To learn or see more, click here. Click here to learn the five steps to PLC program development.

The best way to build the future is to simulate it first.

Watch on YouTube: EXTREME Industrial Switch: 8 Gigabit Ports Survive Anything!

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. This allows you to make a digital twin. See below to receive 10% off this software. This PLC learning package contains the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning digital twin package for less than $95 USD for a single computer installation or less than $110 USD to allow access on multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.