Photoelectric sensors detect the presence or distance of objects in various industrial applications. They typically integrate all necessary optics and electronics into a single unit, requiring only a power source to function and provide an output based on their specifications and the object detection criteria.

Photoelectric sensors, also called photo eyes, detect object presence or distance using light. These sensors use a light source from an emitter and a receiver that detects changes in light intensity reflected or interrupted by the target object. Without physical contact, photo eyes can detect objects at highly close range or out to several meters or more, depending on the specific photo eye technology employed.

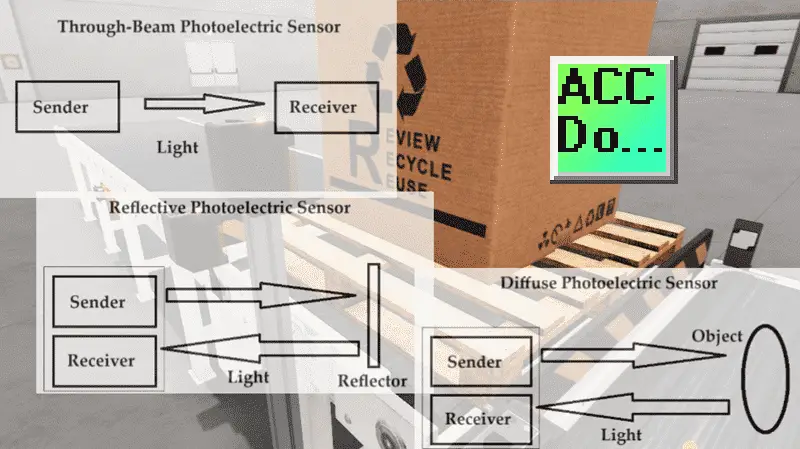

Three basic types of photoelectric sensors exist: through-beam, reflective, and diffuse. The choice of which type to use depends on the specific application. In the following sections, we will review these three types and discuss the reasons for selecting each. Let’s get started.

Additional component connections to PLC include the following:

Here’s a Quick Way to Wire NPN and PNP Devices

– Wiring NPN Sensor to PLC Video

– Wiring PNP Sensor to PLC Video

– Wiring Contact Discrete PLC Inputs Video

Wiring Interposing Relays

– Wiring NPN and PNP sensors into the PLC with an Interposing Relay Video

Click PLC HMI Rotary Encoder Dial Input – Video

Wiring Stack Light to Click PLC – Video

Wiring Push Buttons and Selector Switch to Click PLC – Video

– Test and Assembly of Push Buttons and a Selector Switch – Video

Wiring an Inductive Proximity NPN PNP Sensor to the Click PLC – Video

Wiring a Capacitive Proximity NPN PNP Sensor to the Click PLC – Video

Wiring an Ultrasonic Proximity Sensor to the Click PLC – Video

– Unboxing our UK1F Ultrasonic Proximity Sensor – Video

Universal Signal Conditioner and Isolator – Video

Watch the video below to see how to select a photoelectric (Photo Eye) type based on the object.

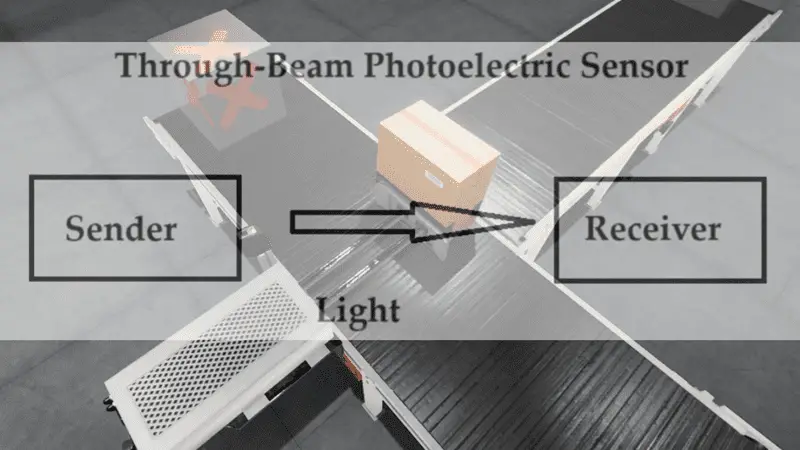

Through-Beam Photoelectric Sensor

A through-beam photoelectric sensor is the first option you should look to when looking for a photo sensor. The sender and receiver are two different units. The sensor will send out the beam of light, and the receiver will sense this unique beam.

These units must be aligned with each other. If the beam of light from the sender is blocked, the sensor output is activated, indicating an object is present. The through-beam photo will provide the most extended range from sender to receiver. However, both sides of the object must be available to mount and wire the sensor. Common everyday use of this photoelectric is for garage door openers. You will typically see these mounted on each side of the garage door to detect objects when the door is closing.

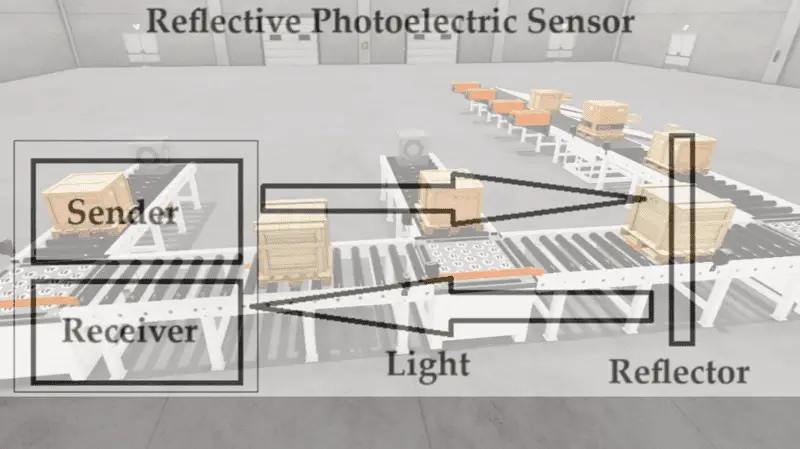

Reflective Photoelectric Sensor

A reflective photoelectric sensor is the next option you should look to for your application. This type of sensor has the sender and receiver in the same unit, so you need to wire just one side. The sensor will send out the beam of light, and a reflector will be used to send this beam back to the receiver.

Blocking the light from the reflector will trigger the output. These sensors are used every day for conveyors. Wiring is done only on one side of the conveyor, and a reflector is mounted on the other. Reflective photoelectric sensors simplify installation, but distance is reduced over the through-beam sensor. Since the beam of light passes through the object twice, this is a good option for translucent or transparent objects, such as glass or plastic, where the light can pass through the object and be reflected to the receiving part of the sensor.

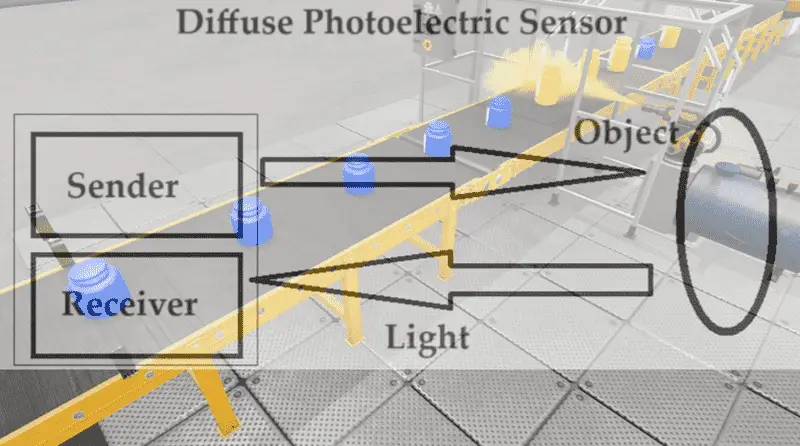

Diffuse Photoelectric Sensor

A diffuse photoelectric sensor, similar to a reflective one, houses the sender and receiver in the same unit. However, this sensor does not require a reflector. The light bounces off the detected object and returns to the receiver.

This type of photoelectric sensor, with the smallest sensing distance, is straightforward to mount, requiring only one location. It is ideal when nothing can be mounted from the other side. This type of sensor has special applications, including color determination, making it a versatile and convenient option.

A photoelectric sensor primarily consists of an emitter that emits light and a receiver that detects light. When the emitted light is interrupted or reflected by a sensing object, it alters the amount of light that reaches the receiver. The receiver detects this change and converts it into an electrical output. We have reviewed the three types of photo sensors and established the order in which we should evaluate them for any application.

One of the most common questions is how to wire three-wire sensors. Click here to see how.

Click here to learn more about PLCs and programming. This is a complete guide.

Watch on YouTube: Revolutionize Object Detection with PHOTOELECTRIC Sensors!

Here is some additional information on wiring PLC inputs.

Wiring NPN Sensor to PLC

https://youtu.be/Z09l3HKMpqs

https://accautomation.ca/heres-a-quick-way-to-wire-npn-and-pnp-devices/

Wiring PNP Sensor to PLC

https://youtu.be/nP33k5e_Y-k

https://accautomation.ca/heres-a-quick-way-to-wire-npn-and-pnp-devices/

Wiring Contact Discrete PLC Inputs

https://www.youtube.com/watch?v=xh5dE2Z09d0

https://accautomation.ca/how-plc-inputs-work/

Wiring Stack Light to Click PLC

https://accautomation.ca/wiring-stack-light-to-click-plc/

https://youtu.be/gwDIVtNSXfs

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. The numbering systems used in PLCs are not challenging to know and understand. We will walk through them, including Bits, Decimal, Hexadecimal, ASCII, and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.