The Productivity 1000 Series PLC uses the Productivity Suite Software. The software can be downloaded free of charge. It is the full package without restrictions or limitations.

The latest Productivity Suite software version is 3.1.0.11. Automation Direct has put 20 years of programmable controller software experience along with customer suggestions and feedback into this programming package. It has great features that we will be exploring as we program our Productivity 1000 Series PLC.

This is the same software that will program the entire Productivity Series of programmable logic controllers.

Productivity 1000 (Stackable Micro PLC)

Productivity 2000 (Micro Modular Programmable Controller)

Productivity 3000 (Modular Programmable Controller)

We will be installing and reviewing the Productivity Suite software version 3.1.0.11.

Let’s get started.

Previously in this Productivity 1000 series PLC we have discussed:

System Hardware – Video

The first thing to do before installing the software is to ensure that your computer can install this software. Here are the basic specifications that you need to install the Productivity Suite software. You will see that the software is not very taxing on any system.

Operating Systems that the Do-More Designer software will run on are the following:

Windows 10

Windows 8.1 – 32 or 64 bit

Windows 8 – 32 or 64 bit

Windows 7 – 32 or 64 bit

Computer specifications:

Video: No graphics specified

Processor: 1GHz (Win 7, Win 8 & Win 10)

Other: USB or Ethernet port for project transfer on P3-550 & P2-550 Ethernet only for project transfer on P3-530 & P3-550E. **Version 2.0.0.x or higher RAM = 2 GB memory (4 GB recommended) **Version 1.10 or lower RAM = 512MB free Ram (1GB recommended)

Download the Software

Productivity Suite Software

http://support.automationdirect.com/products/p3000.html

The above link is the location on the Automation Directs website that you can download the software. While you are on the page, you can also sign up to get a notification each time there is an update for the software. This way you will always have the latest software or at least know about it.

The downloaded file is a zipped file. (prod_software_v3.1.0.11.zip) Using explorer find the downloaded file, right-click on the file and select “Extract All”. This will unzip the file so we can then install it.

The extracted folder will contain one file.

Installing the Software (Productivity Suite)

Double click the install.exe file in the downloaded, uncompressed folder. This will start the installation process.

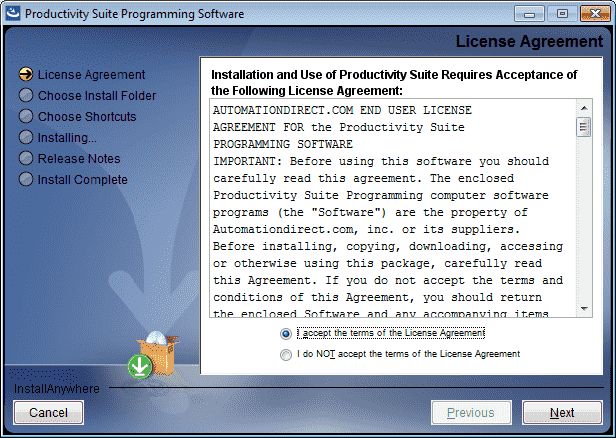

The license agreement window will appear next. You must accept the terms of the license agreement to install the program. Hit Next.

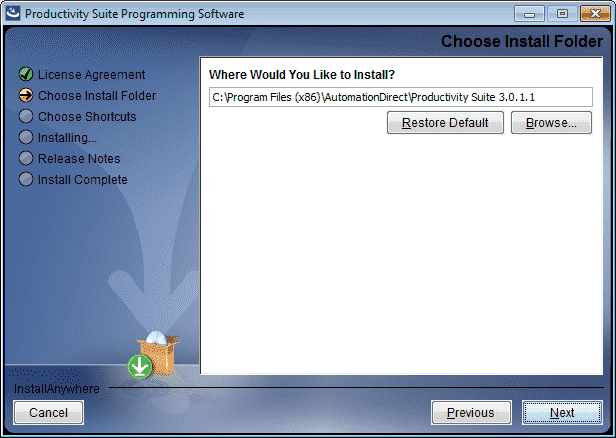

Choose the installation folder. This will default under the program file directory of your computer. We will use the default directory. Hit Next.

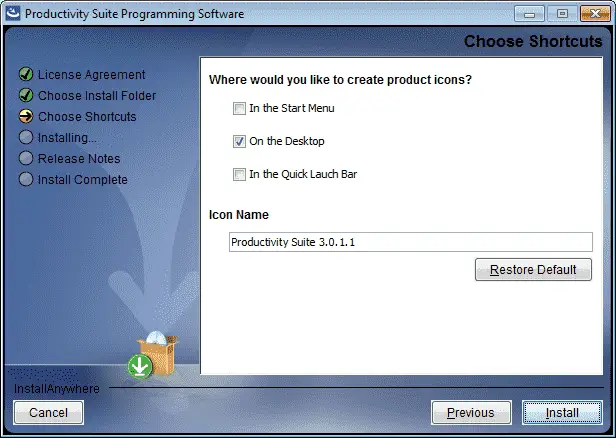

We have the opportunity to now choose shortcuts. We can create product icons and change the icon name. Our installation will be the default icon and name. Hit Install.

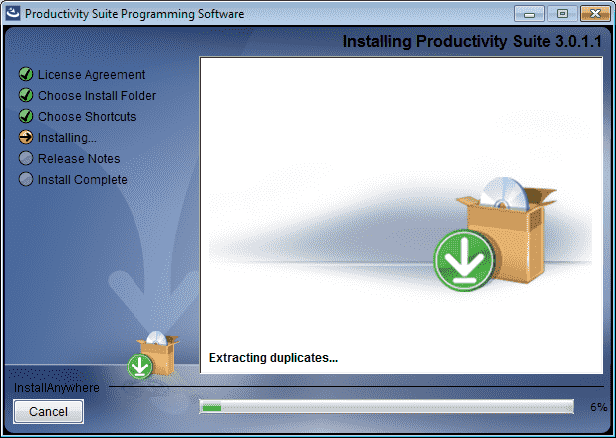

The software will now install. You can hit cancel at any time to stop the process.

After installing the release notes will now be displayed. Once you have read the notes hit next.

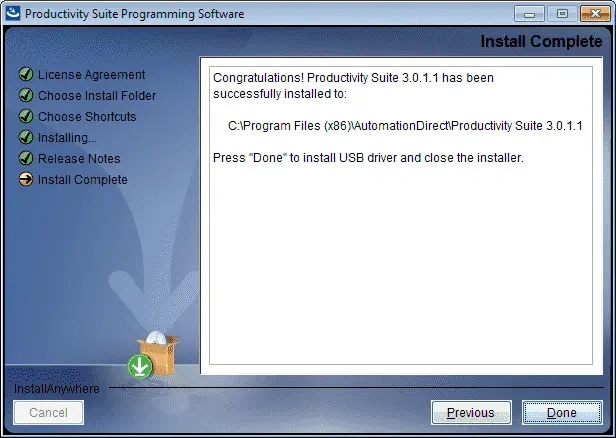

The installation complete message window will now be displayed. Press the Done button.

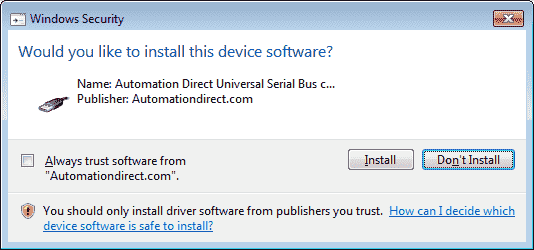

We can now install the Automation Direct Universal Serial Bus communication. (USB Driver)

Hit the Install button in order to install the driver.

Starting the Productivity Suite Software

You will now have an Icon on your desktop to start the software.

You can also start the program by selecting the Start Orb | All Programs | Automation Direct | Productivity Suite 3.1.0.11 | Productivity Suite

The following splash screen will appear as the program loads.

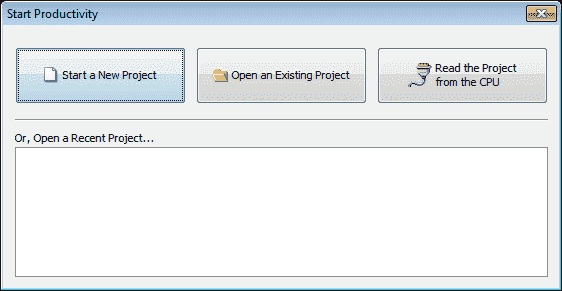

You are now presented with a window that will allow you to start a new project, open an existing project, or read the project from the CPU. There is also a window that will show the last recent projects. This window will help us quickly return to a project that we have stated previously. In our case, we will hit the X in the upper right corner to close the window.

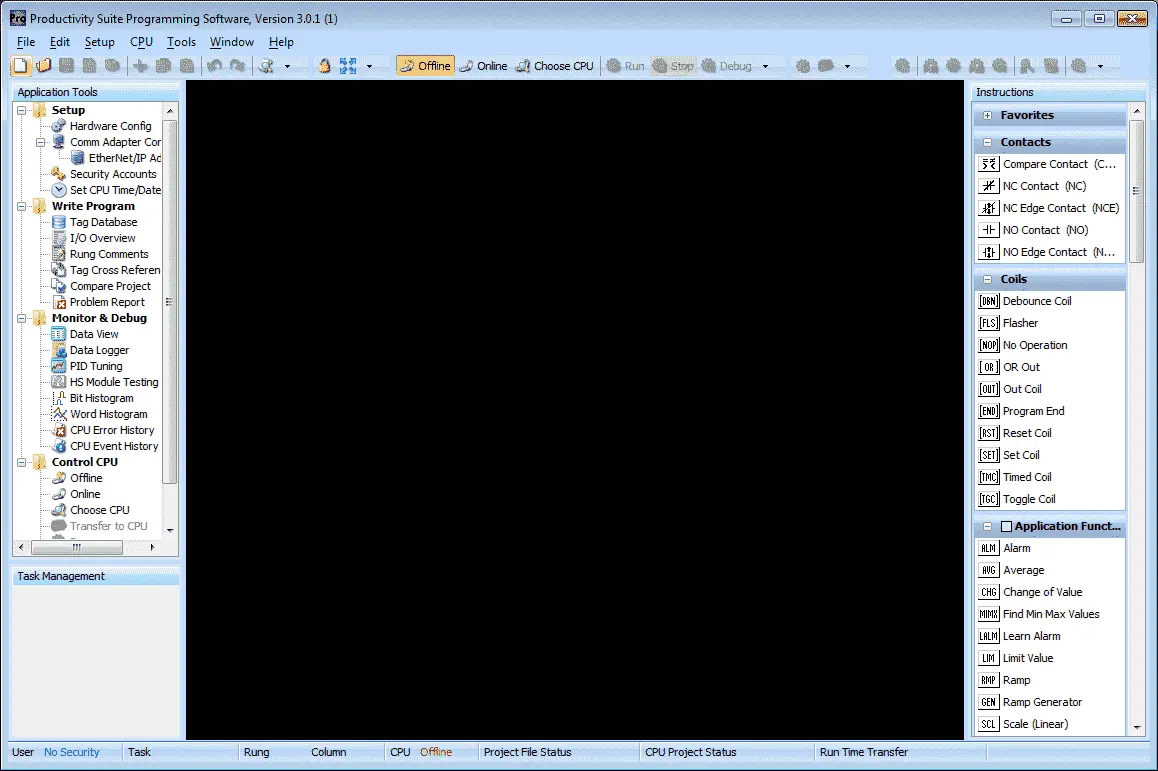

This is the main screen of the program. Here we can see some of the parts that make up this powerful programming software.

User Interface – Main Menu, Toolbars, and Status Bar

Application Tools – Quick access to many of the advanced features. Roll over each topic to see the corresponding dialog box.

Task Management – Here we can break up our ladder logic into separate tasks and drag them into the appropriate category.

Main Ladder / Task Area – This includes all of our Instructions and ladder logic area

The installation of the software is a very straight forward process. You can watch the video below to watch the installation process.

Productivity 1000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Programming Software (Free Download Link)

This software contains all of the instruction sets and help files for the Productivity Series.

Next time we will establish communication (Productivity Suite) to the Productivity 1000 Series PLC.

Watch on YouTube: Productivity 1000 Series PLC Installing the Software

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.