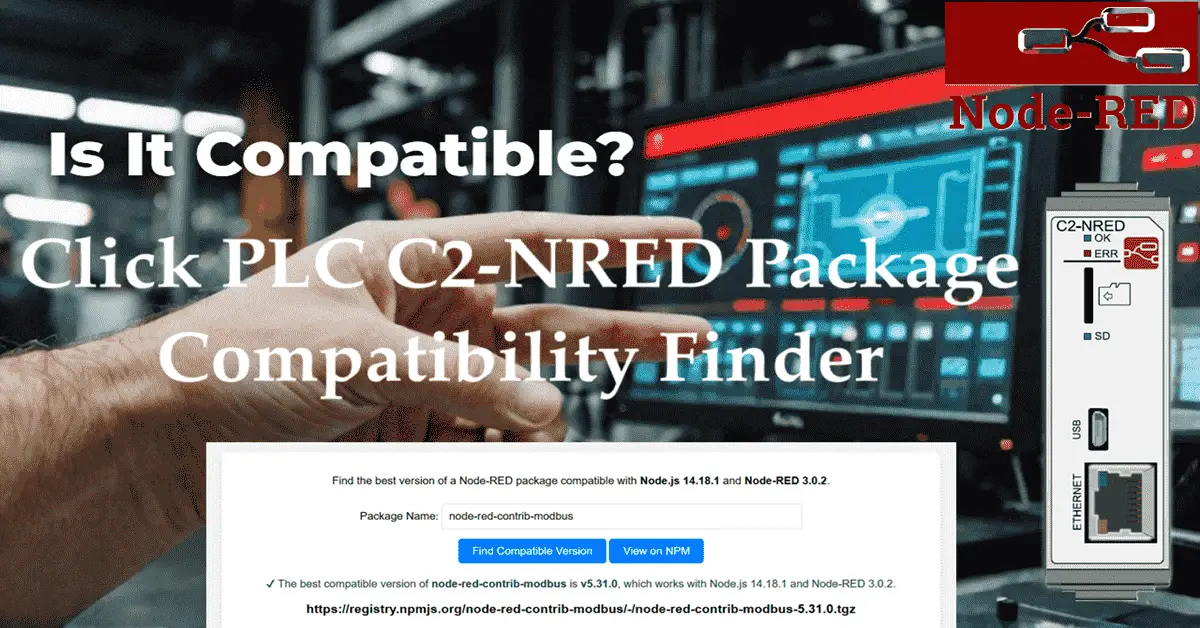

How to Use the Click PLC C2-NRED Package Finder

How to use the C2-NRED Package Compatibility Finder… Are you wondering if your Node-RED program package is compatible with the Click PLUS PLC C2-NRED module? How do you find the correct C2-NRED package? This is the most common frustration with the C2-NRED Node-RED module for the Click PLC. This Node-Red module currently has version 3.0.2 … Read more