Changing Landscape of PLC Programming

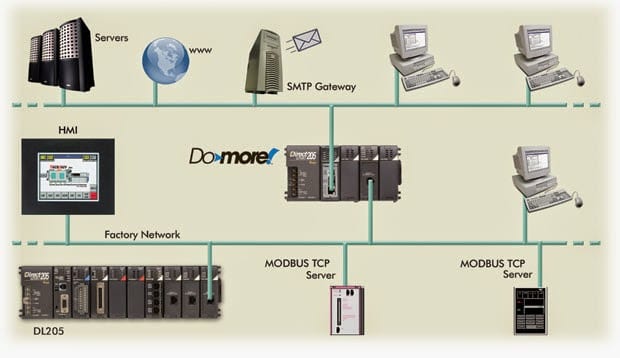

With today’s new processing and networking power, the future looks bright for programmable logic controllers and their programming. This has allowed the role of the PLC to expand. System Design: PLC design has changed significantly. Computer processing power has now added the following to programmable controllers: Micro USB slots (Data Storage) Ethernet ports WiFi RS232 … Read more