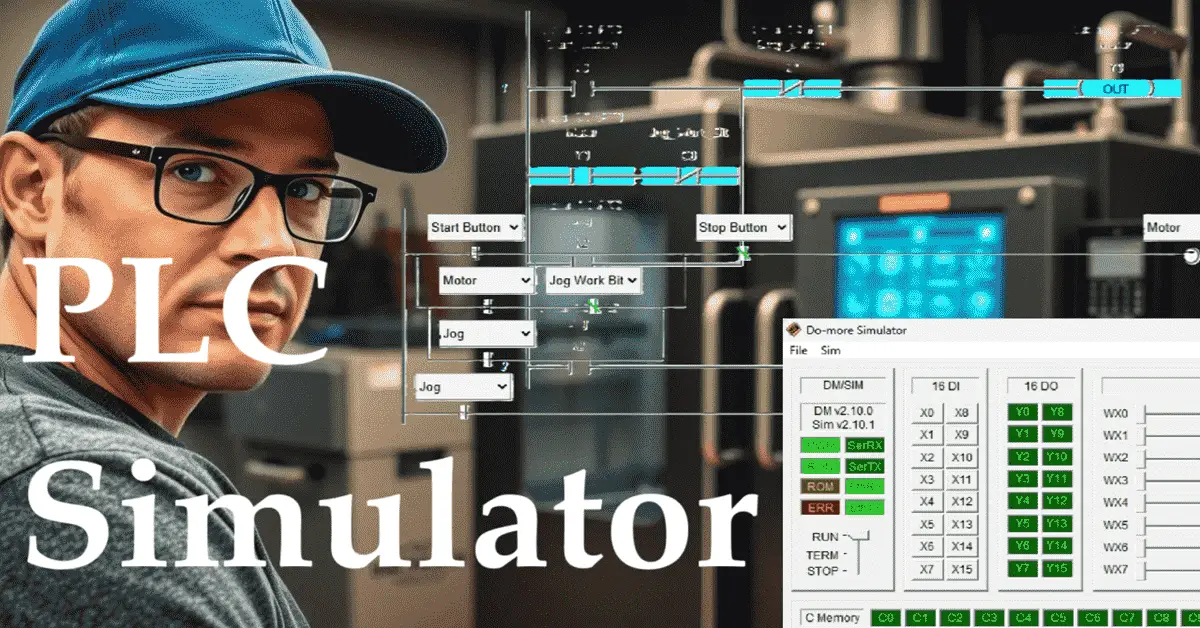

PLC Simulator CONQUER Your Automation Potential!

PLC (Programmable Logic Controllers) can significantly reduce the cost of manufacturing a machine. The PLC programming can be reduced as much as 50% with the use of simulators. A PLC Simulator is a piece of software that enables a programmer to test their code without the need for hardware. This means that the logic can … Read more