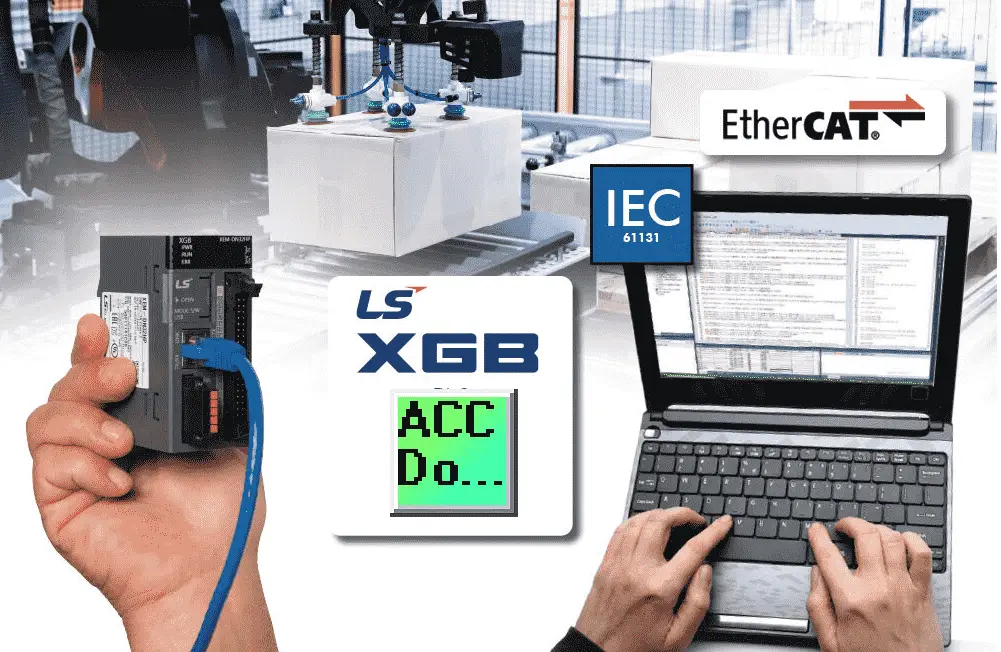

The LS XGB PLC is a compact industrial controller with advanced motion control capabilities and an IEC programming environment.

The FREE programming software allows you to program in several IEC standard PLC languages, such as ladder diagram (LD), structured text (ST), sequential function chart (SFC), and instruction list (IL). User-defined functions/tags and easy tag creation like “Excel®” make this software versatile.

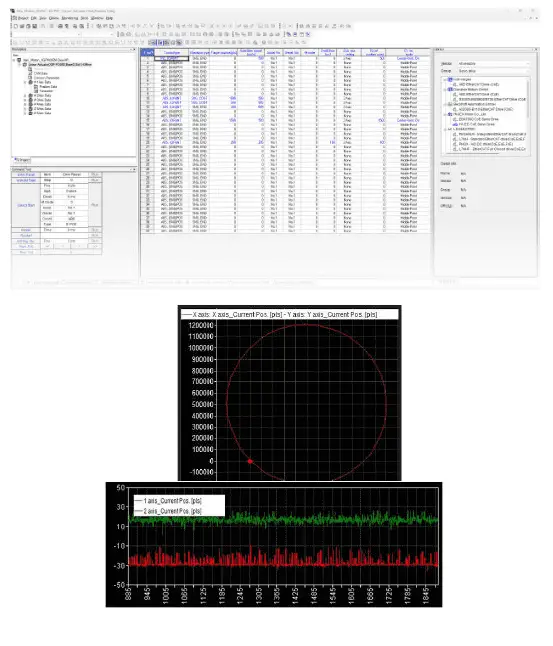

The LS Electric XGB PLC provides advanced motion control for up to 22 axes, with up to 6 axes embedded on the CPU and up to 16 axes using EtherCAT® modules. You can choose from several positioning methods, including linear, circular, helical, and ellipse interpolation. Additionally, the device offers seven homing routines, and you can use the FREE software to access a graphical interface that allows you to observe the motion in action.

This series will focus on the XGB PLC and how to quickly and easily get it up and running. Each post will have a corresponding video to demonstrate the concepts discussed. Let’s start.

Who is LS Electric?

LS Electric was founded in 1974 as Lucky Packing Co. and has been a leader in the Korean electric industry ever since. Their mission is to deliver safe and effective energy solutions worldwide. With headquarters in South Korea, the company expanded quickly across Asia and overseas markets, including the United States and Europe. In the 1980s, the company shifted its focus to automation products, specifically PLCs, AC, and servo drives. The 1990s brought continued growth and innovation, confirming LS Electric as an automation industry expert and a global energy leader. In 2017, the company was nominated as one of the top 100 businesses in the world for patent applications in Europe. In 2018, LS Electric sold 3 million units of a single-drive model, marking another year of great success for the company.

LS Electric Automation CIC started the 2020 new year with a new name, aiming to establish a strong foundation for sustainability and offer customers comprehensive automation solutions using cutting-edge technology.

With nearly 40 years of experience in the electric power industry, LS Electric now manufactures and distributes a wide range of power, automation, and railway solutions to customers in Korea and worldwide. It is recognized as one of the top 10 Korean enterprises, with global production facilities and offices. Watch the video below to see the unboxing and powering of the XGB PLC.

What is the XGB PLC?

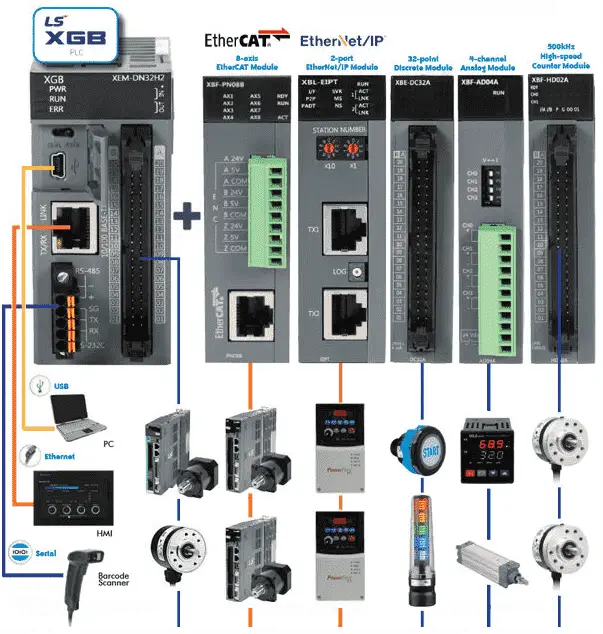

The LS XGB PLC is a compact industrial controller with free programming software packages. The software includes advanced motion control capabilities and an IEC programming environment. The LS Electric XGB PLC comes in four different-type stand-alone controllers with 32 built-in IO. NPN or PNP IO versions, along with 2-axis or 6-axis versions, are the version options for your system. Add up to 7 expansion modules for up to 244 additional I/O points. The LS PLC has the hardware for everything from the smallest machine to the largest systems.

Summary of the XGB PLC CPU Units:

- Four stackable micro PLC processors with 16 inputs and 16 outputs that include motion capability

- 2-axis and 6-axis versions

- NPN and PNP I/O versions

- Four high-speed counter inputs, four preset inputs

- Ethernet, serial, and USB ports

- Supports up to 7 expansion modules, including analog, discrete, high-speed counter, EtherCAT, and EtherNet/IP modules

The LS XGB PLCs are known for their incredibly small size, with the 32-point LS PLCs taking up less space than the 14-point compact CLICK PLCs. Despite their compact design, the LS controller is packed with advanced capabilities, making it a powerful option for those who need to save space while still having access to all the features you require. Watch the video below to see the unboxing and powering of the XGB PLC.

Variety of Input and Output (IO) for the XGB PLC

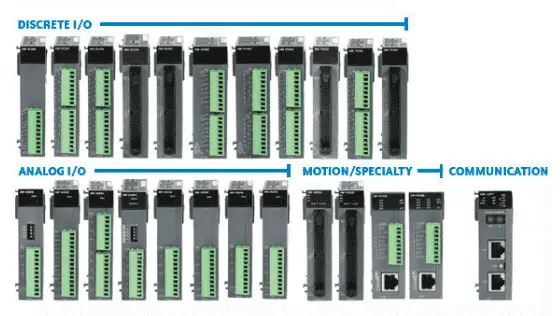

Various I/O expansion modules are available to provide the analog, high-speed, motion control, communication, and additional discrete I/O needed for larger or more complex systems.

- 24 expansion modules, including cost-effective high-density 32-point I/O modules

- Discrete (11) – in, out, combo in/out, and relay modules

- Analog (8) – in, out, and combo in/out modules

- Motion/Specialty (4) – EtherCAT 4- and 8-axis positioning modules; high-speed counters 200kHz or 500kHz

- Communication (1) – EtherNet/IP module

XGB Motion Controller

The LS Electric XGB series controller is a highly capable motion control device offering various features. The CPU module has 2- or 6-axis pulse/direction motion inputs/outputs (up to 200kHz) that enable numerous motion control capabilities. The high-speed counter module also provides up to 4 channels of high-speed inputs that can handle up to 500kHz on each input. Furthermore, the EtherCAT modules allow for up to 16 axes of motion control. The advanced motion features of LS XGB PLC make it an excellent choice for any motion control application.

- 400 moves per axis

- Various single-axis operations: position control, speed control, feed control, multi-axis simultaneous start, and point operation

- Various multi-axis operations: circular arc interpolation (up to 3 groups, two axes per one group), linear interpolation (up to 6 axes), helical interpolation, ellipse interpolation

- Switching control during operation: position/speed control switching, speed/position control switching, position/torque control switching

- CAM control: 8 types

- Seven homing methods: in positioning control, use the Homing method supported by each servo driver (17 types); set the origin of the machine without homing by setting the floating origin

- Acceleration/deceleration methods of Trapezoid or S-type

- High-speed start process: 1ms (1~2 axes), 2ms (3~5 axes), 3ms (6 axes); no delay time between axes in simultaneous start and interpolation start

Motion configuration software for accurate positioning

XG-PM software is free of charge in the same download as the XG5000 programming software. This software provides table-based position configurations of up to 400 moves per axis and a run command tool for easy position testing. The XG-PM software also has a System View feature that allows all six axes to be seen at once, and any modifications needed to the motion profiles can be made without touching the user program. For validation, convenient 2D-dimensional trend graphs of position configurations are provided, and the XG-PM software utilizes an intuitive error code system for easy troubleshooting.

XGB EtherCAT protocol

The EtherCAT protocol (Ethernet for Control Automation Technology) is an Ethernet fieldbus that provides industry-leading performance, flexibility, and cost advantages. The functional principle – processing data on the fly – makes the EtherCAT network extremely fast and capable of real-time, deterministic communication with virtually unlimited nodes that can be synchronized for the highest precision. Other advantages include:

- Less wiring for complex motion applications sends signals over the network instead of hardwired.

- Extremely fast cycle times

- Multiple topologies can be used

- Built-in redundancy – network can detect a break

- CANopen over EtherCAT (CoE) device profiles allow easy addition of 3rd party devices.

One software package does it all!

The FREE IEC Programming XG5000 software package includes the Drive CM utility, which allows you to configure any LS servo drive easily. Once configured, the file can be uploaded directly to the drive and edited, saved, and downloaded as needed. Drive CM can operate the servo system from a PC, allowing the servo to perform basic motion and check the I/O. A powerful scope function is also provided that allows the user to display as many as four data channels simultaneously.

The LS Electric XGB PLC comes equipped to tackle numerous industrial processes, not just advanced motion control. With high-density 32-point discrete I/O modules, a wide variety of “on/off” controls are possible, or add XGB analog modules to your controller for up to 16 PID loops. XGB PID control is extremely capable and offers numerous features, including:

- Easy auto-tune function

- Cascade control with a master loop and slave loop

- PWM capability

- Pause capability

- Forward/reverse output

- Helpful trending capabilities for PID values

Up to 16 PID loops with easy auto-tuning!

With LS XGB PLC analog modules, you can monitor and control various processes around your facility, including those involving:

Watch on YouTube: Transform Automation with LS XGB PLC: The Solution – Unboxing and Powering

LS XGB PLC Additional Information:

LS XGB PLC – Series

– FAQ – Frequently Asked Questions

Product Cut Sheet (XEM-DN32H2 Unit Specifications)

LS PLC Technical Specifications

Manuals:

Interactive Guide

LS PLC User Manual

Other Documents:

PLC Installation Guide

Product Brochure

PLC Statement of Direction

Software and Support:

XG5000 / XG-PM PLC Programming Software

XEM PLC Firmware

Quick Start Procedures

XEM Pulse Servo Wiring Diagrams

Example Applications Directory

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to know and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.