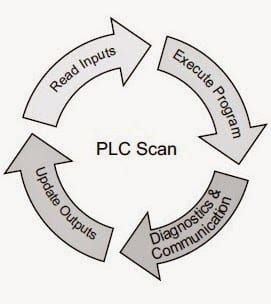

A one-shot in the PLC will turn an output on for one scan. This is used to trigger events that should only happen once. An example of this would be to increment a value in memory. If a one-shot is not used, then every scan of the PLC will increment the value.

What is a one-shot in the PLC?

A PLC one-shot is also known by several other names. Differential Up (DIFU), Differential Down (DIFD), One Shot Relay (OSR), Powerflow Modifier, Leading edge contact, Trailing edge contact, etc. This all relates to the programmable controller that you are programming.

PLC Examples of One-Shots

Let’s take a look at programming a one-shot using bit logic only. We will program both a leading edge one-shot and a trailing edge one-shot bit. This program will work in all PLCs.

Note: The white background in the increment (INC) instruction indicates the reset for the animation.

Leading Edge One-Shot Bit Example

Leading-edge one-shot bit: This will turn on a bit for one scan when the input condition makes a transition from 0 to 1. (Off to on)

When input X0 turns on, C0 is turned on for one scan. This is because it is in series with the C1 lead work bit. The next rung will latch this on and not unlatch it until the input condition X0 turns off. C0 will only be on for one scan when X0 turns on.

Trailing-Edge One-Shot Bit Example

Trailing edge one-shot bit: This will turn on a bit for one scan when the input condition transitions from 1 to 0. (On to off)

When input X0 turns off, C2 is turned on for one scan. This is because it is in series with the C3 trail work bit. The next rung will latch this on and not unlatch it until the input condition X0 turns off.

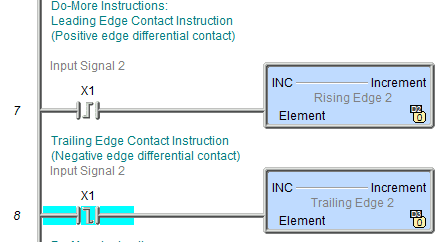

The Do-more PLC has several ways to do the leading and trailing edge one-shots. Here is a couple:

The leading or trailing edge contact instruction will allow logic flow for one scan from a transition. (On to off / Off to on)

The leading and trailing edge Powerflow Modifier is placed before the output. It will turn multiple input signals into a one-shot for the output.

Watch on YouTube: How to Make a One-Shot in the PLC

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.