Programmable Logic Controller (PLC) programming is often thought of as something everyone can do easily. We often design the system, install the hardware and then start to think about the PLC program and programmers. This approach can be improved. The landscape of PLC programming is changing, and we must also change.

Computer Programming / PLC Programming

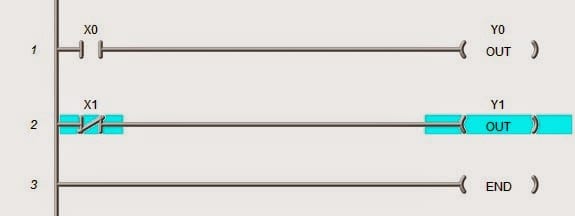

I believe that with all of the new functions of the PLC processor, you would be better served by someone that can do additional computer programming. Ladder logic has been taught in our schools for about 20 years. The basic bit programming in the ladder is easily understood. Connecting to the manufacturer’s dedicated software shows the power flow from left to right and the logic solved from top to bottom.

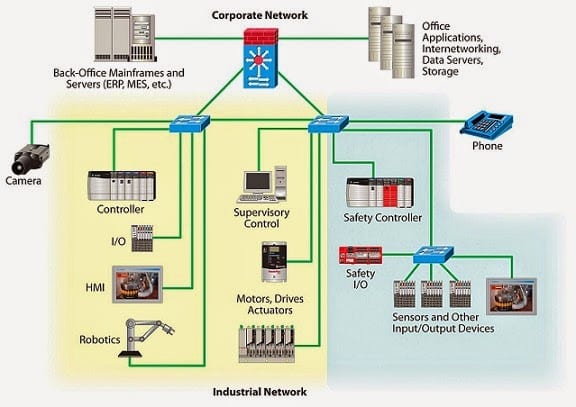

Some applications are acceptable if you replace a few relays; however, today’s manufacturing floor must be integrated. The existing hardware in the plant must also be connected to the PLC system. This will allow the connection of data logging, email, vision system, motion control, HMI, computer servers, etc.

Ladder logic and the standardization of PLCs on the plant floor have long been a topic for discussion and debate. The benefits were that anyone could look at and understand the PLC logic to troubleshoot the system. Today the PLC can do a lot more. Visually it can indicate /display its troubleshooting and diagnostics to the engineer, electrician, and operator in various ways. Using HMI (Human Machine Interface), computer screens, indication lights, and email, to name a few, information can be passed for troubleshooting and diagnostics. You no longer need the skills on the plant floor all of the time. Investing in the program and system integration in your plant will pay for itself repeatedly.

I believe that PLC programmers need more than just this programming language. They must have the network and high-level language skills to integrate the entire plant floor.

Let me know what you think. Are we teaching the new generation the right way?

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.