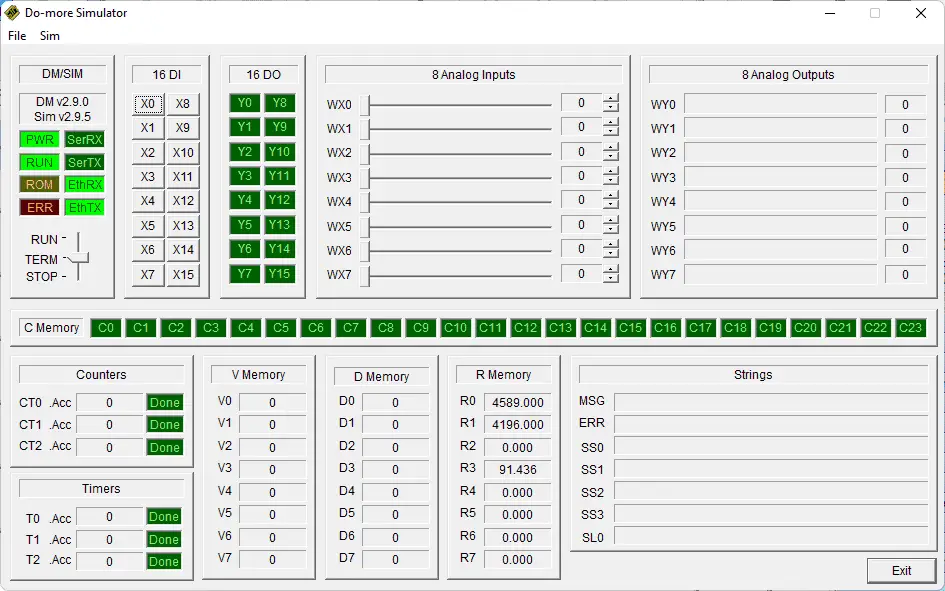

We can learn plc free by using the Do-More Designer simulator. This is free, fully functional programming and simulator software. The PLC simulator also allows communication through the Ethernet and Serial ports of the computer to help you learn about HMI and communication. This video series will take you through the simulator’s basics of installing, programming, and testing your ladder logic programs.

No physical hardware is required to learn how to program programmable logic controllers (PLC). This series was initially released six years ago but is still relevant today and is part of our PLC beginner’s guide.

No physical hardware is required to learn how to program programmable logic controllers (PLC). This series was initially released six years ago but is still relevant today and is part of our PLC beginner’s guide.

We will briefly discuss each of the videos in this series and provide the URL links. Let’s get started.

Learn PLC Programming – Free – Installing the Software

Installing this award-winning software is the first step in your PLC programming learning.

This video will show you how to download, unzip, install, and start the PLC Programming Software.

The latest version of the Do-More Designer Programming Software can be found here.

The latest version of the Do-More Designer Programming Software can be found here.

See the links and information below on this ladder logic programming software.

Learn PLC Programming – Free 2 – Your First PLC Program

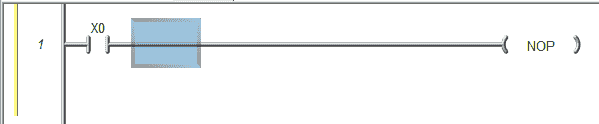

We will now create your first plc program. This will create input and activate an output in ladder logic. The two lines of ladder logic code will then be downloaded to the simulator and tested.

This video will include starting a new online PLC program, simulator modes, edit mode, entering the PLC ladder logic code, switching to run mode on the PLC simulator, and entering more PLC ladder logic.

This video will include starting a new online PLC program, simulator modes, edit mode, entering the PLC ladder logic code, switching to run mode on the PLC simulator, and entering more PLC ladder logic.

The simulator is ideal for testing and running your logic before the actual hardware.

The simulator is ideal for testing and running your logic before the actual hardware.

Learn PLC Programming – Free 3 – Program Documentation

Ladder logic program documentation is one of the most important things to do in your program, but it is often not done. This will save you time and money when you try to remember what specific code is trying to accomplish.

This video will walk you through the documentation options for your first program on the Do-More Designer Software. As mentioned before is the most important part of PLC programming.

This video will walk you through the documentation options for your first program on the Do-More Designer Software. As mentioned before is the most important part of PLC programming.

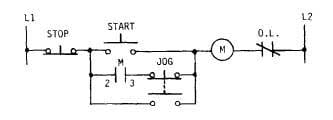

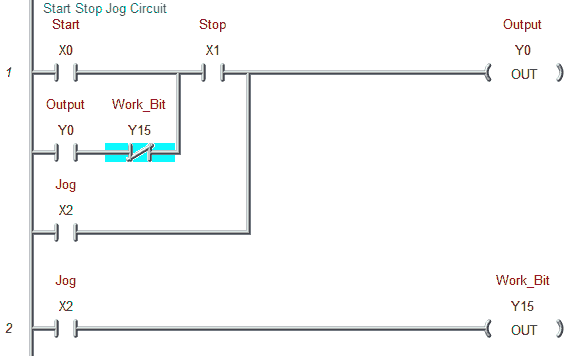

Learn PLC Programming – Free 4 – Start / Stop / Jog Circuit

The start, stop, and jog circuit is one of the most used circuits in ladder logic. We will now look at the ladder logic program in our PLC.

We will look at two starts/stops with jog circuits. One uses familiar conventional circuits in the PLC, and the other uses Set and Reset instructions.

This video will teach about the cyclic scan time of the PLC. Trigger on the leading or trailing edge of the input signal is also discussed.

This video will teach about the cyclic scan time of the PLC. Trigger on the leading or trailing edge of the input signal is also discussed.

Learn PLC Programming – Free 5 – Jog Circuit Memory Retentive

Memory can be retentive or nonretentive. Looking at the start/stop with jog circuits we built last time. We will make this memory retentive.  This means that if the PLC stops or power is removed, the previous state of the output will be remembered. Initial starting conditions must always be considered when powering up your PLC.

This means that if the PLC stops or power is removed, the previous state of the output will be remembered. Initial starting conditions must always be considered when powering up your PLC.

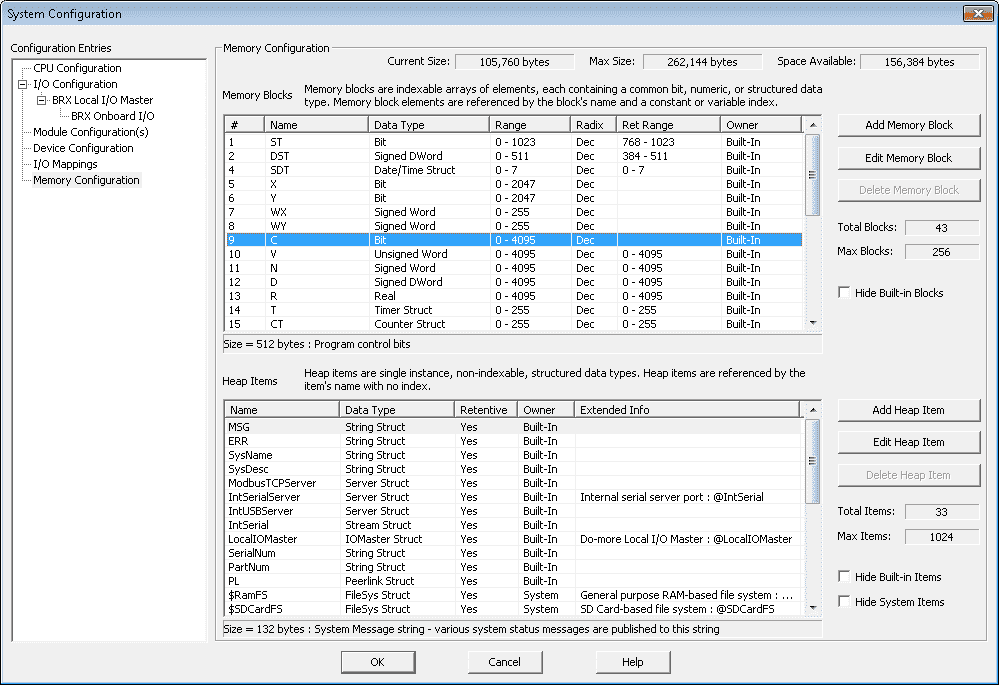

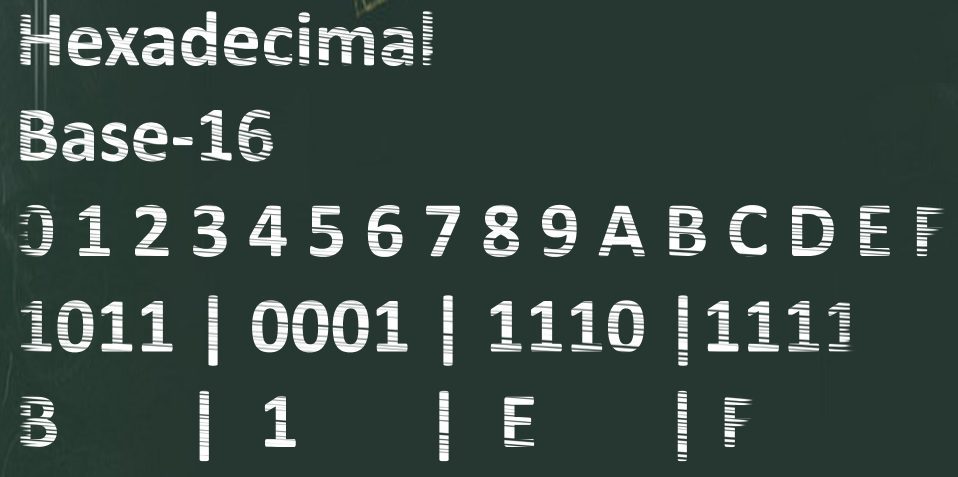

Learn PLC Programming – Free 6 – Decimal / Binary Numbering in the PLC

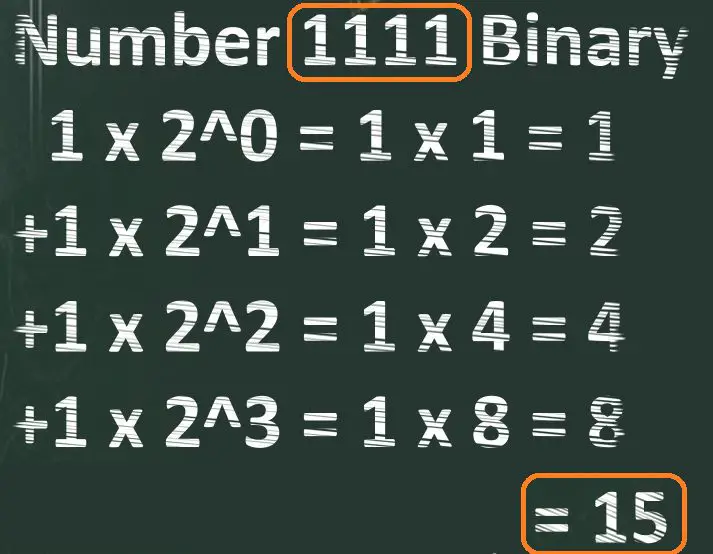

How often have you heard that everything in the computer or PLC is on or off? In this video, we will explain how the numbering systems are implemented in the computer / PLC.

Decimal, Hexadecimal, and Binary Numbering Systems are explained using groups of discrete on/off bits.

Decimal, Hexadecimal, and Binary Numbering Systems are explained using groups of discrete on/off bits.

Learn PLC Programming – Free 7 – Binary Interpretation

The PLC will only understand 1 or 0 (on and off). We look at how numbers are understood in the system. BCD / Hex / ASCII systems are discussed related to the PLC.

For more specific information on numbering systems, here is a post on What Everybody Ought to Know about PLC Number Systems.

For more specific information on numbering systems, here is a post on What Everybody Ought to Know about PLC Number Systems.

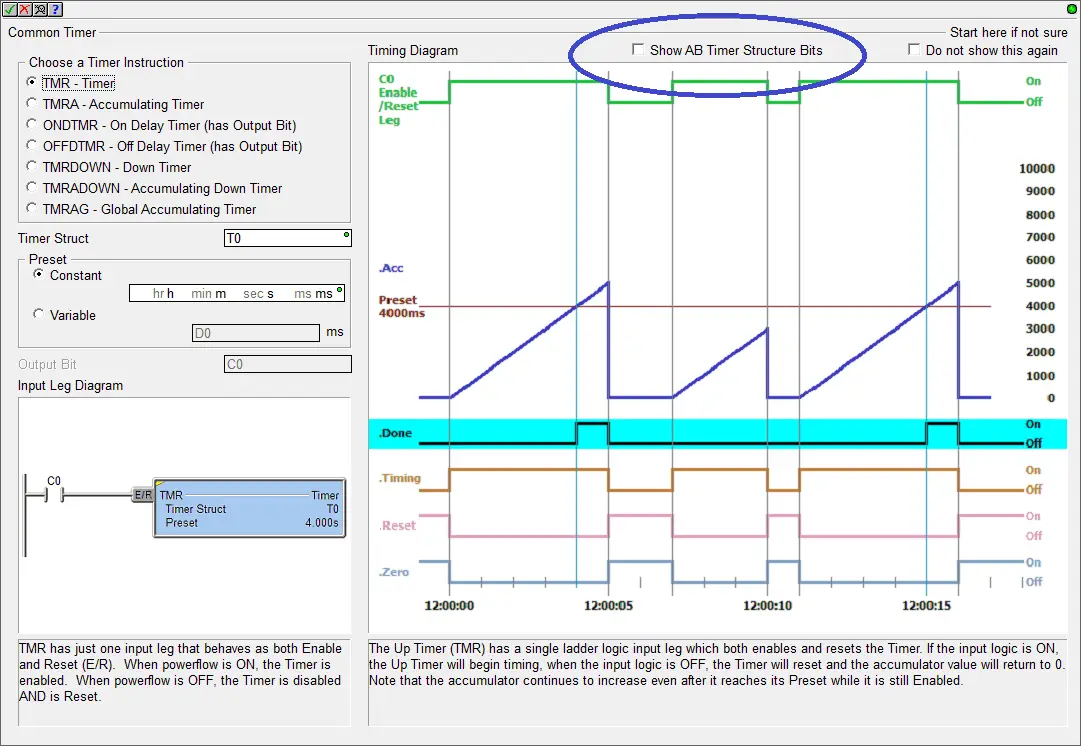

Learn PLC Programming – Free 8 – The Secret of Timers in the PLC

Timers are used in most PLC programs. There are also a wide variety of off-the-shelf industrial timers that you can use. The implementation of timers can be vast; however, it all starts with a TIMING CHART.  This video shows you how to read and use a timing chart for your PLC program.

This video shows you how to read and use a timing chart for your PLC program.

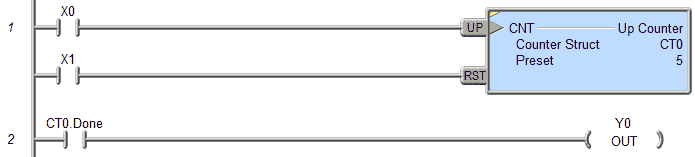

Learn PLC Programming – Free 9 – The Secret of Counters in the PLC

We will now look at the secret of using counters in the PLC. Counters are used in most PLC programs, as well as timers. This is especially true if part of your SCADA system. There are also a wide variety of off-the-shelf industrial counters that you can use. The implementation of counters also starts with a TIMING CHART.

This video will show you how to use the counter in the PLC program.

This video will show you how to use the counter in the PLC program.

The entire playlist for learning PLC programming can be found here.

The above videos will get you started learning PLC programming without spending any money. You can then expand your knowledge with specific details of the PLC controller model you want to invest in. The above information will help you determine if programming is something that you want to pursue.

The PLC Beginner’s Guide to PLC Programming is a good place for additional information on coding.

Download the Do-More Designer ladder logic programming software here.

Do-more Designer PLC Programming Software

Full-featured programming software for Do-more Series PLCs

Do-more Designer™ is the full-featured PLC programming software for the Do-more™ series of programmable logic controllers (PLCs). Flexible program management supports a mix of stage and ladder logic for a best-of-both-worlds approach that simplifies programming and makes troubleshooting easier. Do-more Designer Software is a free download from the Automationdirect.com Web site. A CD-ROM version is also available for purchase.

Do-More Designer Software Brochure

Do-more Designer Programming Software Features:

It’s Free! … Do more! Designer [Download Now]

– Same software for all Do-more! and BRX Product Lines

Easy Navigation Software Dashboard

– With quick links to important tools and screens

Built-in Software Videos

– Getting started videos, instructional videos, download utility

Built-in Simulator

– Creates a virtual PLC to test program logic without a PLC present

Local I/O is Automatically Configured

– The I/O config window shows the auto-discovery of modules in the local base

Optimized instruction set

– Based on customer requests and developed with flexibility and ease of use

Powerful, Intuitive Math

– Allows mixing of data types and accepts formulas and variables

High-speed I/O and Motion Control: Simplified

– Dedicated instructions allow you to choose the complexity

Communications Are Easy

– To define, troubleshoot and share data over serial/Ethernet

Data Logging & File Management

– 1MB internal RAM storage with microSD support and email capabilities

Free learning and training series for PLCs.

BRX Do-More

Productivity Series

P1000

P2000

Click / Click PLUS (Koyo)

Omron CP1H Series

Horner XL4 Series

EasyPLC Software Suite – 3D training package

Purchase your copy of this learning package for less than $75 USD for a single computer install or less than $100 USD to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/

Learn PLC programming the easy way. Invest in yourself today.

C-More EA9 Series of HMI

(Webserver, FTP, Data Logging, Free Remote Apps, etc.)

Node-Red is a free IoT software hub that can communicate MQTT and many standard industrial protocols. This series will help you communicate to the PLC, create an HMI on any electronic device, log data to a database, and view the information on a spreadsheet for analysis.

Node-RED IoT enabling software

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.