You’ve had this idea for years since you were a kid. You want to be an electrical engineer, and you’re finally going to follow through on it and learn PLC programming to start your career off right! What? That’s what you thought, anyway. But then you started googling around, trying to figure out how to begin learning PLC programming, and it sounds like it will take forever! How are you supposed to know which software is the best option? Which hardware should you buy?

We will look at three steps to kick off your PLC programming and determine if this learning is proper for you. Let’s get started.

We will look at three steps to kick off your PLC programming and determine if this learning is proper for you. Let’s get started.

1) Focus on One PLC

What is a PLC?

PLC stands for Programmable Logic Controller. These devices are used in many industries and serve as the central communication hub for machines and equipment. The plc takes instructions from a computer program, executes them, and communicates with the connected system.

You can learn how these devices work by installing software on your computer, purchasing hardware, and practicing with it. It’s a straightforward process requiring minimal start-up cost or knowledge of electronics or mechanics. All PLCs have this kind of functionality.

You can learn how these devices work by installing software on your computer, purchasing hardware, and practicing with it. It’s a straightforward process requiring minimal start-up cost or knowledge of electronics or mechanics. All PLCs have this kind of functionality.

It is essential to focus on one model of PLC. Learning all about this controller will give you a great base of understanding when viewing other PLC manufacturers. When programming the programmable logic controller, you need to know everything about the controller, machine, and system. Understanding the details of one PLC will help you fully understand its capabilities without being detracted by comparisons of other PLCs. Once you have this detailed understanding, looking at different models will become easier because you now have a personal frame of reference.

It is essential to focus on one model of PLC. Learning all about this controller will give you a great base of understanding when viewing other PLC manufacturers. When programming the programmable logic controller, you need to know everything about the controller, machine, and system. Understanding the details of one PLC will help you fully understand its capabilities without being detracted by comparisons of other PLCs. Once you have this detailed understanding, looking at different models will become easier because you now have a personal frame of reference.

I would recommend starting with one particular model to learn about PLC programming.

What model to choose? Ask around in your local area where you want to work. Who is the manufacturer that they are recommending? Check the help wanted section and determine the skills and systems they want to be programmed and maintained.

Concentrating on one manufacturer and PLC model will help you learn more quicker and more in-depth than any other method. Once you know about a particular model, different models will have more or fewer features so that the learning curve will be shortened.

Concentrating on one manufacturer and PLC model will help you learn more quicker and more in-depth than any other method. Once you know about a particular model, different models will have more or fewer features so that the learning curve will be shortened.

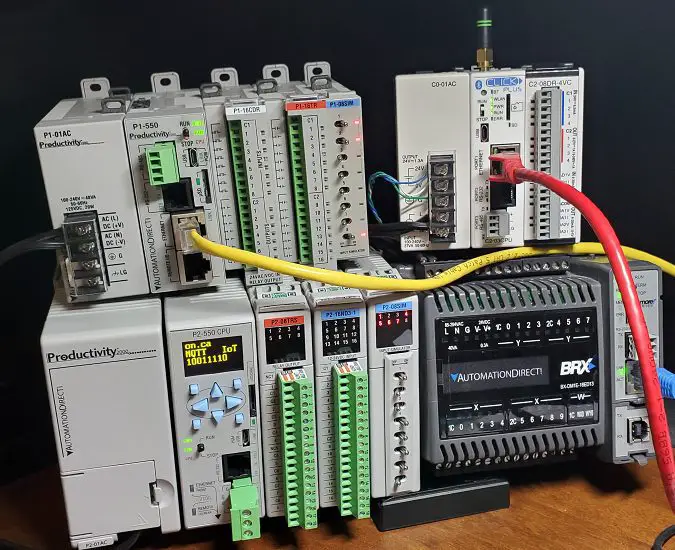

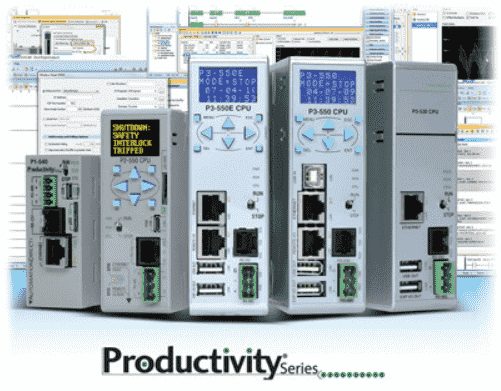

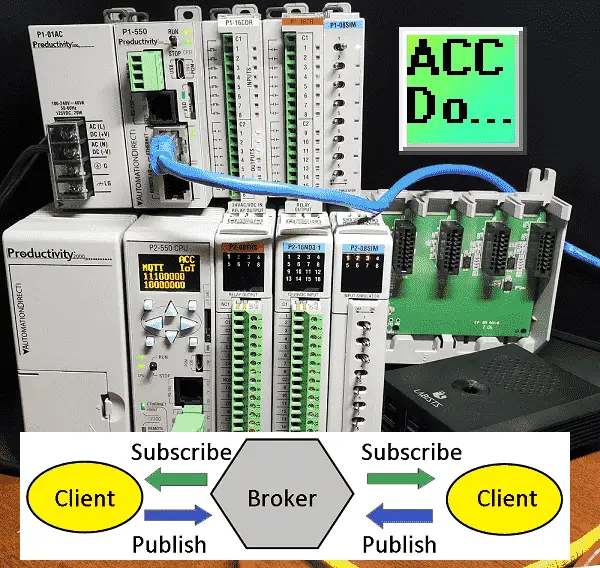

If you are stuck on a model to learn, I would suggest Productivity PLC, which closely relates to Allen Bradley without the investment cost. If you are still unsure, an IIoT type of PLC controller is also a good option. The BRX Do-More PLC with the Do-More Designer is a great option.

Download the operation and programming manual and read up on your PLC controller’s features.

Download the operation and programming manual and read up on your PLC controller’s features.

2) Install the Software

Once you know the model you want to learn, find out what software program you will need for programming. Every manufacturer has its programming software for its PLC controllers. Efforts are being made to standardize this through industry standards like IEC 6113-3.

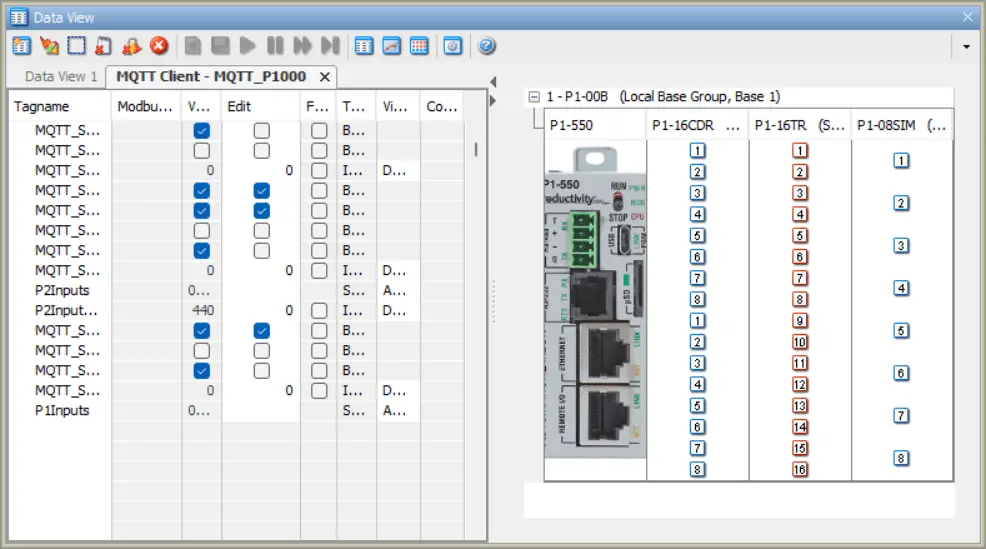

CODESYS has this compliance and has different hardware developers globally, but this still has not hit the mainstream. You should be able to try out the software free of charge. A good starting point is downloading a trial version of the software for whichever plc you try to learn how to program. Sometimes you can download the complete programming package like the Productivity Programming Software or the Do-More Designer Software free of charge. If you cannot find a demo version of the software, contact your local distributor and see if they can get you a copy.

Installing the software will let you see if the software is what you need and if you like PLC programming. It is better to find out now than after you have spent money on hardware and software that will gather dust. Typically you will start learning ladder logic programming. This is the most common type of programming language for PLC. Most of the software will be able to use this on your controller. Spend time in the help menu of the programming software. You will usually find a variety of quick starters to help you understand and learn this software.

Typically you will start learning ladder logic programming. This is the most common type of programming language for PLC. Most of the software will be able to use this on your controller. Spend time in the help menu of the programming software. You will usually find a variety of quick starters to help you understand and learn this software.

3) Practice Makes Perfect

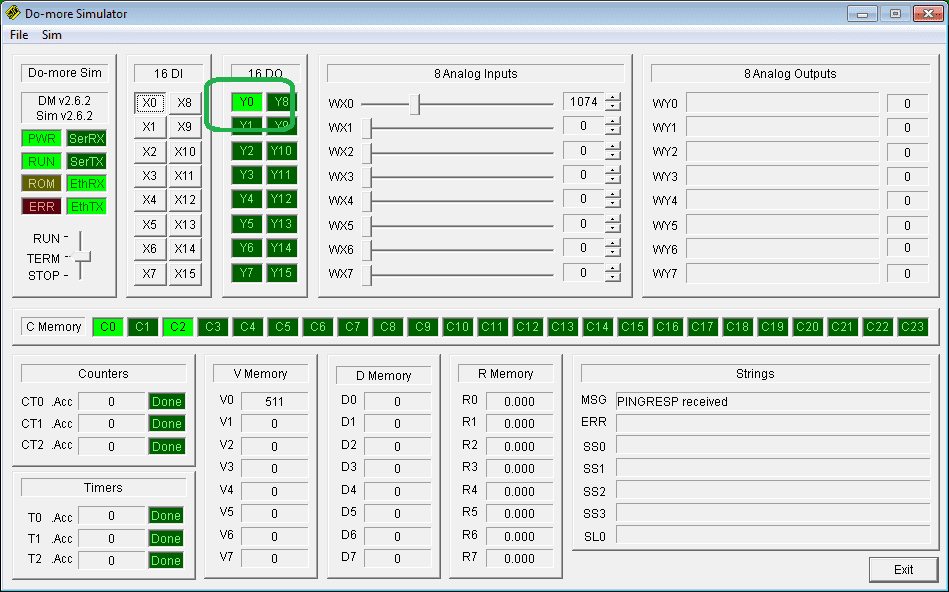

Software packages like Productivity Programming and Do-More Designer have built-in simulators. This will allow you to run your ladder logic sample program on a simulator. No hardware is required to practice and see your program run.

The next step would be purchasing the physical hardware so that you can practice wiring and programming your new plc. Practice your ladder logic programming skills and have something to use as a test before tackling a large job. Practice on small projects or simple circuits until you are ready for more significant tasks like teaching others or replacing malfunctioning equipment at work.

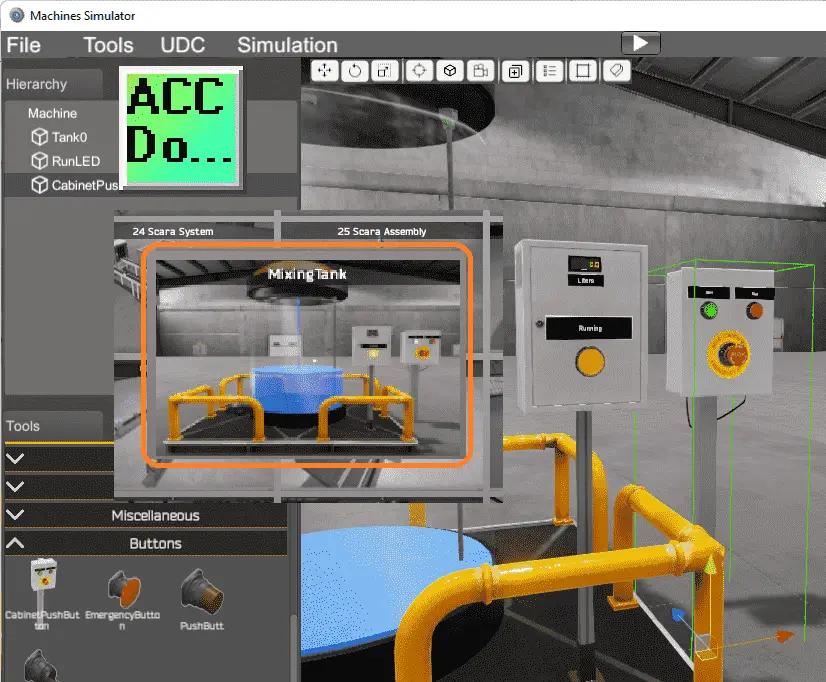

The next step would be purchasing the physical hardware so that you can practice wiring and programming your new plc. Practice your ladder logic programming skills and have something to use as a test before tackling a large job. Practice on small projects or simple circuits until you are ready for more significant tasks like teaching others or replacing malfunctioning equipment at work. Three-dimensional simulators are also available to help you improve your programming skills. EasyPLC software suite is one of the best low-investment programs that will allow you to practice on prebuilt machines. You can also make your own. This software will help in your program development skills.

Three-dimensional simulators are also available to help you improve your programming skills. EasyPLC software suite is one of the best low-investment programs that will allow you to practice on prebuilt machines. You can also make your own. This software will help in your program development skills.

There are several things to remember while looking for hardware and plc basics programming information.

There are several things to remember while looking for hardware and plc basics programming information.

– Make sure your information is related to your hardware and software setup.

– Look through the PLC forums to find sample programs to try and duplicate on your hardware.

– Review the essential information for every PLC.

Naturally, you might feel a little overwhelmed when you start. Don’t be afraid to take the plunge! Concentrating on the one controller model and software will focus your energy so you can know everything about the PLC. You will then have a reference to learn about other systems and software. Once you get some experience and start producing quality work, it’ll feel great.

Watch the video below to see the three steps to PLC programming.

Free learning and training series for PLCs.

BRX Do-More

Productivity Series

P1000

P2000

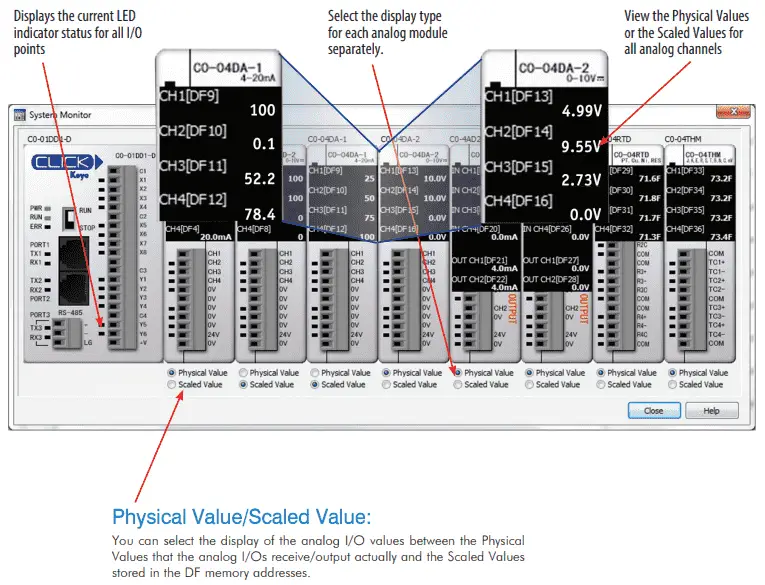

Click / Click PLUS (Koyo)

Omron CP1H Series

Horner XL4 Series

EasyPLC Software Suite – 3D training package

Purchase your copy of this learning package for less than $75 USD for a single computer install, or less than $100 USD to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/

Learn PLC programming the easy way. Invest in yourself today.

C-More EA9 Series of HMI

(Webserver, FTP, Data Logging, Free Remote Apps, etc.)

Node-Red is a free IoT software hub that can communicate MQTT and many standard industrial protocols. This series will help you communicate to the PLC, create an HMI on any electronic device, log data to a database, and view the information on a spreadsheet for analysis.

Node-RED IoT enabling software

Watch on YouTube: 3 Steps to PLC Programming – Learning

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.