What is a PLC Simulator?

Online vs Offline Simulators

Online and Offline simulators are often confused with online and offline communication to the physical Programmable Logic Controller (PLC).

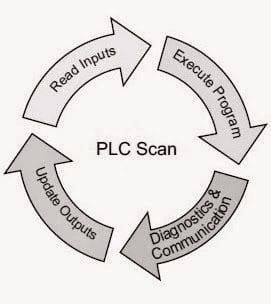

Since we do not need hardware with the PLC simulator, our programs are tested in a virtual environment on a computer.

An online PLC simulator requires an internet connection and operates within your web browser. The online version of this simulator needs an internet connection. Since it runs in your browser, no software is installed on your computer. Online PLC simulators are generally used for learning and training in basic PLC programming concepts. The program’s instruction set typically provides fundamental programming, making it an ideal choice for learning.

An offline PLC simulator is typically a software package provided by a manufacturer of programmable logic controllers (PLCs). This simulator enables you to test and troubleshoot your PLC logic without requiring physical hardware. You download and install the software on your computer, where you can program your PLC logic using the manufacturer’s tools. After programming, you can test your logic using the included PLC simulator. We will now explore examples of both online and offline PLC simulators.

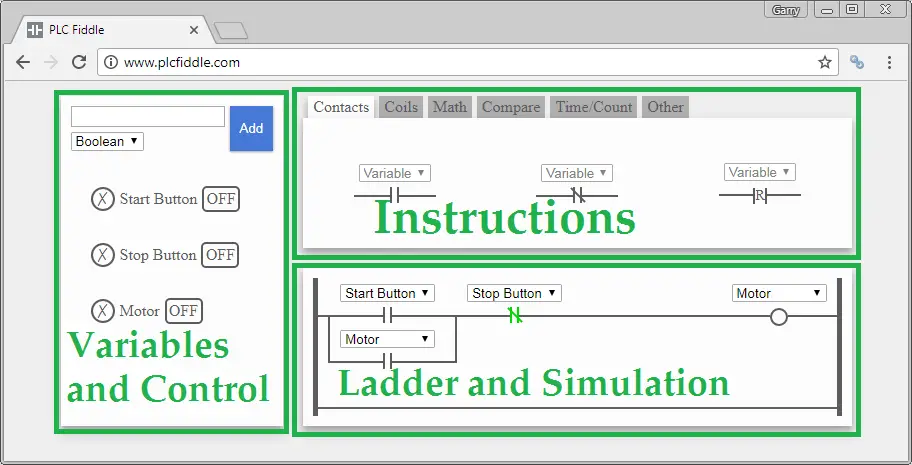

PLC Fiddle – Online PLC Simulator

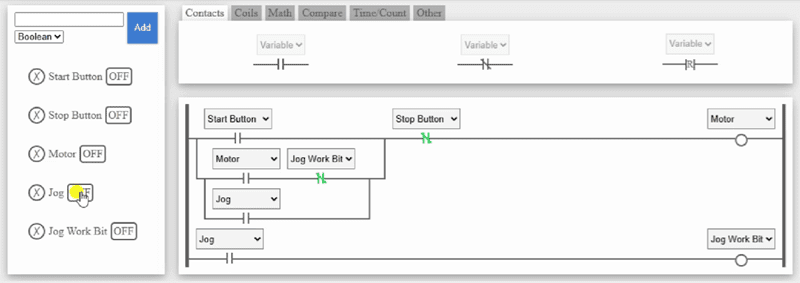

The software consists of three main parts: Variables and Control, Instructions, and Ladder and Simulation.

Let’s now create an example.

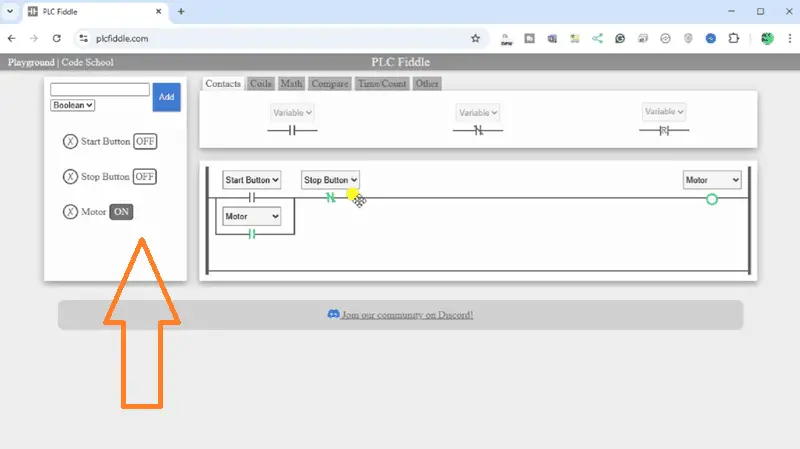

You will see that when we start PLC Fiddle, a start-stop circuit has already been made. When we select the OFF button in the Variables and Control, this will turn the variable ON. Our ladder logic constantly scans and turns on the motor. The motor remains on even after the start button is turned off.

This is due to the motor parallel sealing contact under the start button. The stop button, when turned on, will stop the motor.

Let’s add a jog function to this existing ladder logic start-stop control.

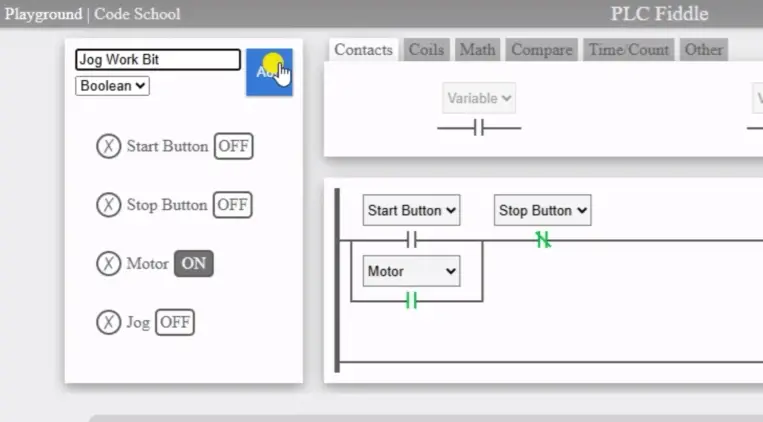

Add two more Boolean variables, Jog and Jog Work Bit.

The jog function will allow the motor to run only while the jog is activated. When it turns OFF, the motor will stop.

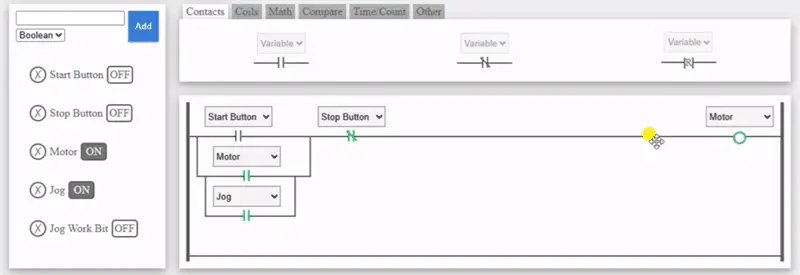

Under the motor sealing contact, add the jog. We can immediately test our circuit since our ladder logic is constantly being solved. Selecting the Jog will turn on the motor, but it will not turn off the motor when the Jog is turned off. This is due to the scan of the PLC.

We must create a delay for the motor sealing contact when using the jog.

Use the jog contact to turn on the Jog Work Bit on a new ladder logic rung.

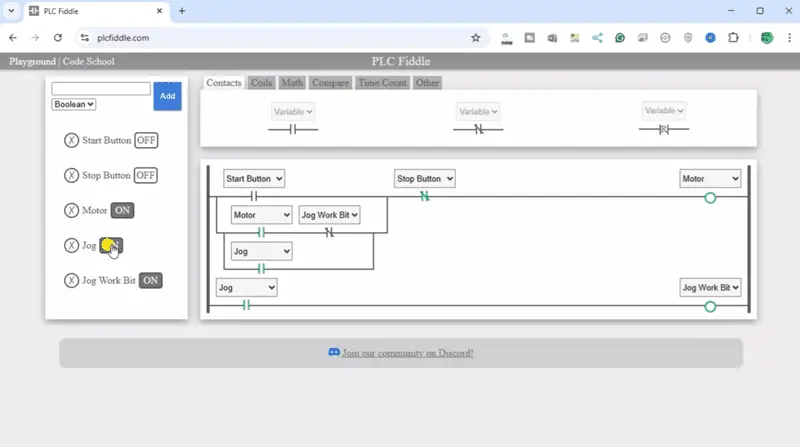

Add the normally closed jog work bit beside the motor sealing contact. Operate your logic.

The Jog button now functions as expected, and the motor stops when Jog mode is turned off. Watch the video below to see this in operation.

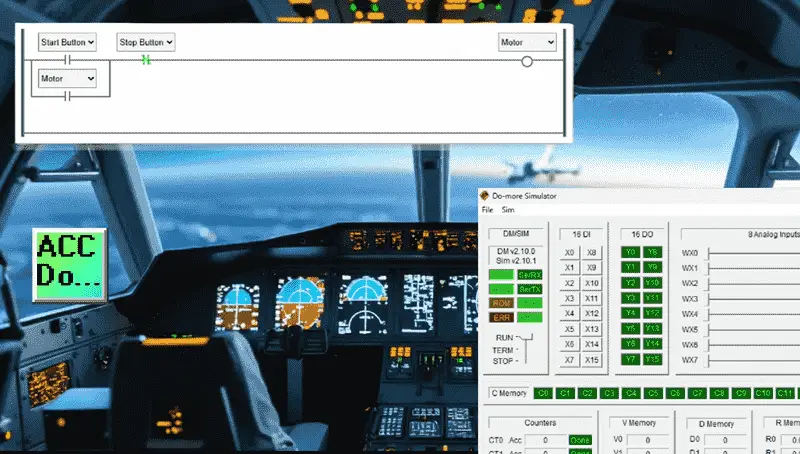

Do-More Designer Software – Offline PLC Simulator

Unlike the online version of PLC simulators, the offline PLC simulator requires a download to operate. Software is installed from the PLC manufacturer’s website onto your computer. One of the easiest offline PLC simulators is in the Do-More Designer Programming Software.

Typically, the offline PLC simulator demonstrates the ability to communicate both online and offline with the simulator. This provides a more accurate representation of how physical hardware will function. The instruction set for the PLC is typically the same as the manufacturer’s hardware, providing a precise representation of the logic being executed.

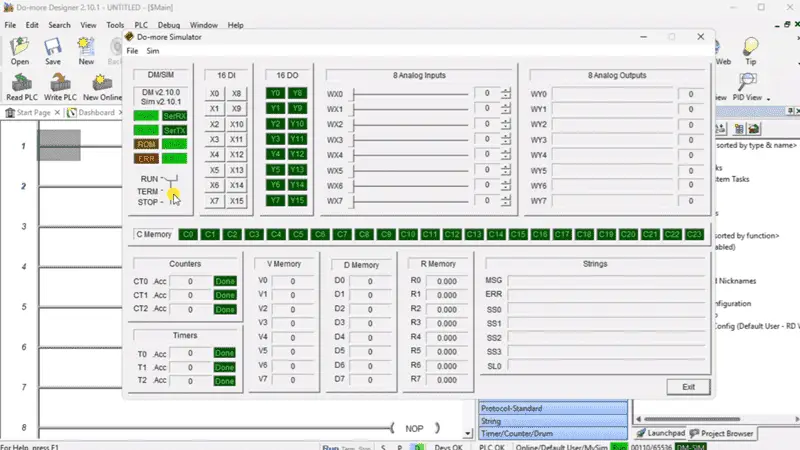

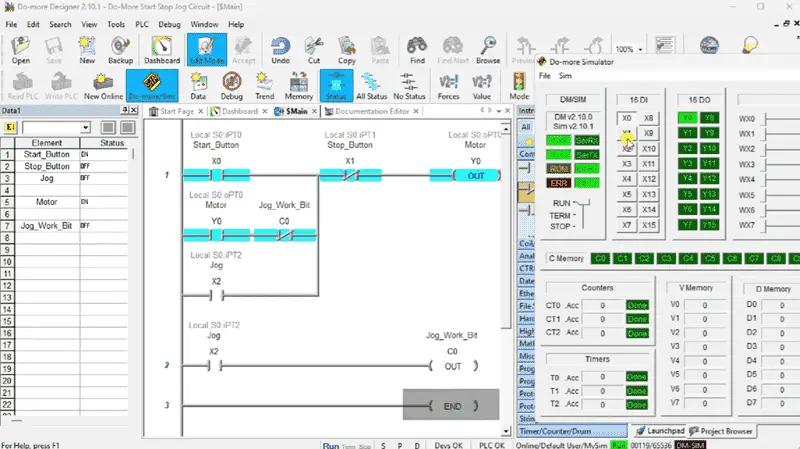

Our Do-More Designer PLC Simulator appears as follows. We can control the inputs, whether discrete or analog, and observe the output function according to our logic.

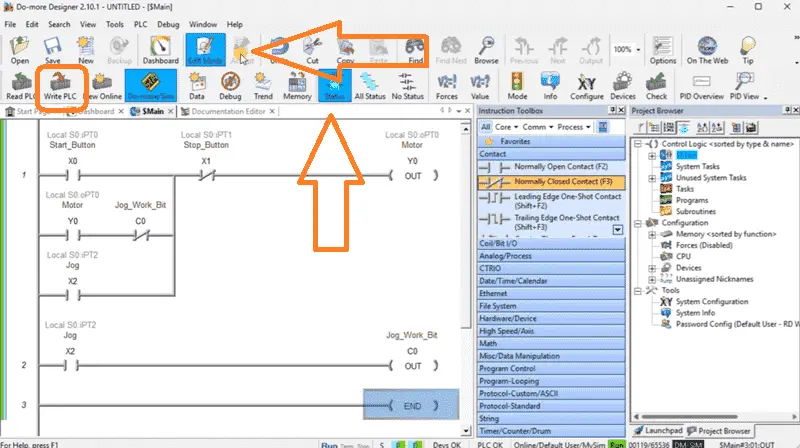

Let’s enter our ladder logic for the Start-Stop Jog circuit, just as we did with the PLC Fiddle online simulator.

Once we have entered our logic, we can accept it. This will check the syntax of the code to ensure that no errors are present when it compiles. Use the write to PLC icon to transfer our program.

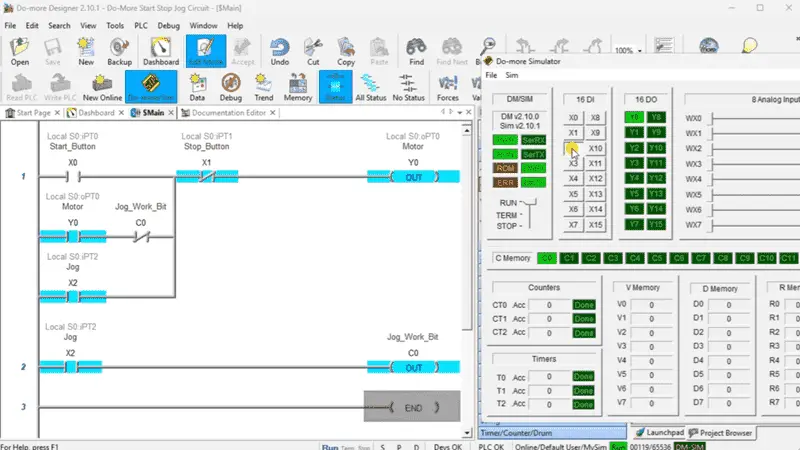

Select the status icon to view the status of our logic as it is being solved.

We can now operate the inputs to ensure that our ladder logic circuit works. Since this is a fully functional programming software, we can use additional tools like Data View to see variables for our program.

Since this software is installed on your computer, we can also use the simulator to communicate through the serial and Ethernet ports. This can test additional equipment on your system. The built-in simulator functions just like a physical Do-More PLC, enabling you to immerse yourself in the world of automation. Watch the video below to see this simulator operate.

Click here to download the PLC Simulator program that we just created.

Our PLC Fiddle Series can be found here.

There are many different PLC manufacturers, each offering their hardware and software. All programmable logic controllers share similar basic features. Here is how I would approach learning about basic Programmable Logic Controllers (PLCs).

Our entire BRX Do-More series can be found here. The FAQ page for the BRX Do-More can be found here.

BRX Series PLC from Automation Direct – Power to deliver

Overview Link (Configure and purchase a system)

Manuals and Product Inserts (Installation and Setup Instructions)

Do-More Designer Software (Free Download Link) – The software will contain all of the instruction sets and help files for the BRX Series PLC.

Watch on YouTube: The Secret to Perfect PLC Edge Detection Revealed!

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point. To get this free article, subscribe to my free email newsletter.

Use the information to inform others how numbering systems work. Sign up now. The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.