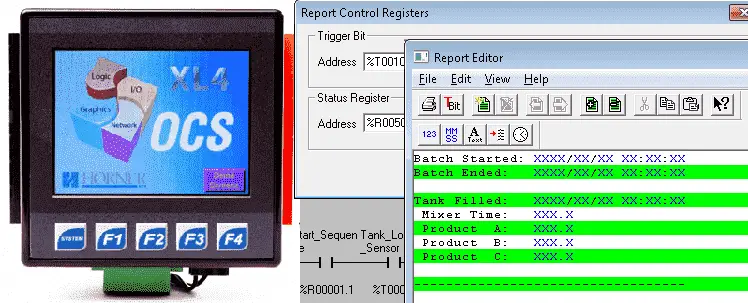

Horner XL4 Report Generator – Text / Data

We will now look at the Horner report generator. The Horner APG XL4 all in one controller has a feature to generate text reports. These reports can consist of text and data from memory locations in the controller. Reports can be printed using a serial interface printer through any of the serial ports of the … Read more