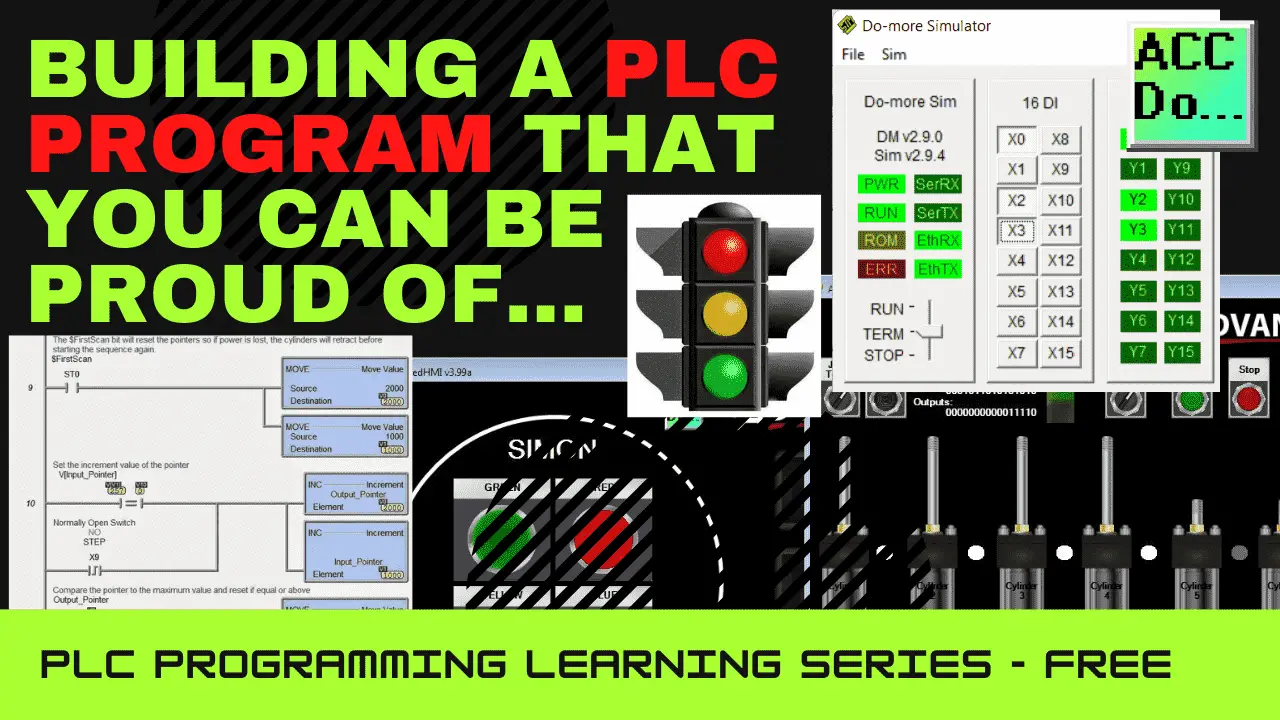

Building a PLC Program that you can be Proud of

Building a PLC program series will take you through developing and programming PLC logic. This six-part series was released almost seven years ago but is still relevant today. Each part will add and build upon the previous step. This series will look at different ways to solve the same machine logic. Using discrete inputs and … Read more