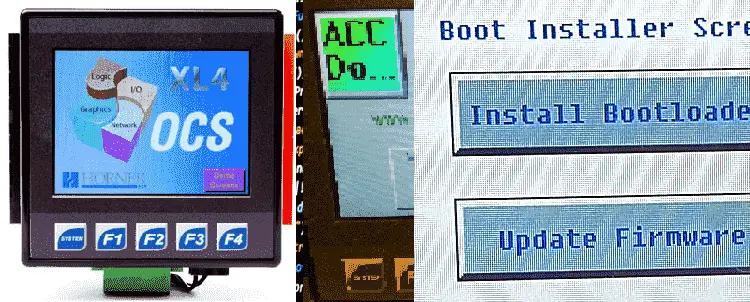

Horner XL4 Firmware Update – All In One

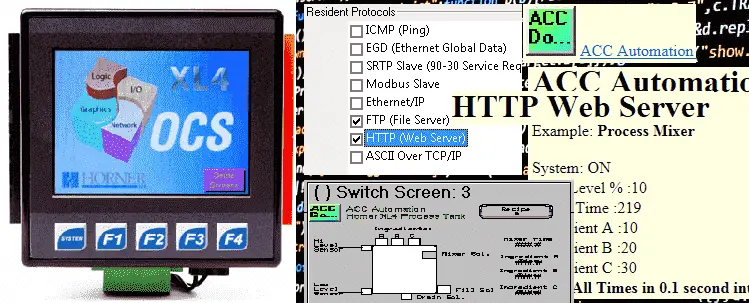

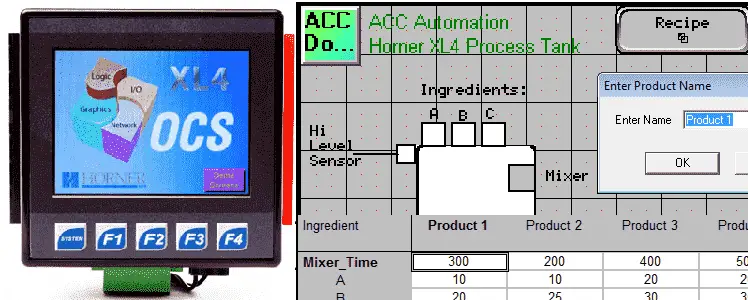

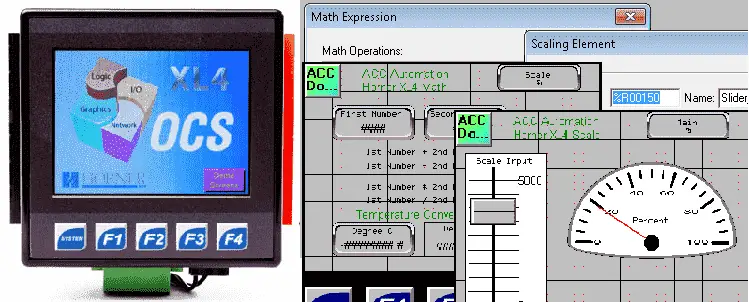

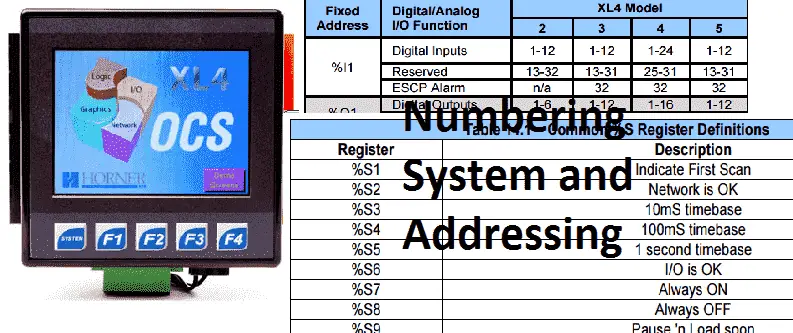

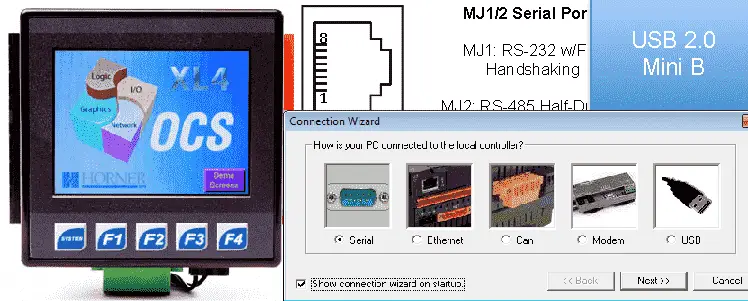

We will now look at changing the firmware on our Horner APG XL4 controller. The firmware update will give users the newest version of the operating system which adds new benefits to the controller. The firmware update is also required when changing communications between CsCan and CANopen. CsCan is a peer-to-peer network by Horner Electric … Read more