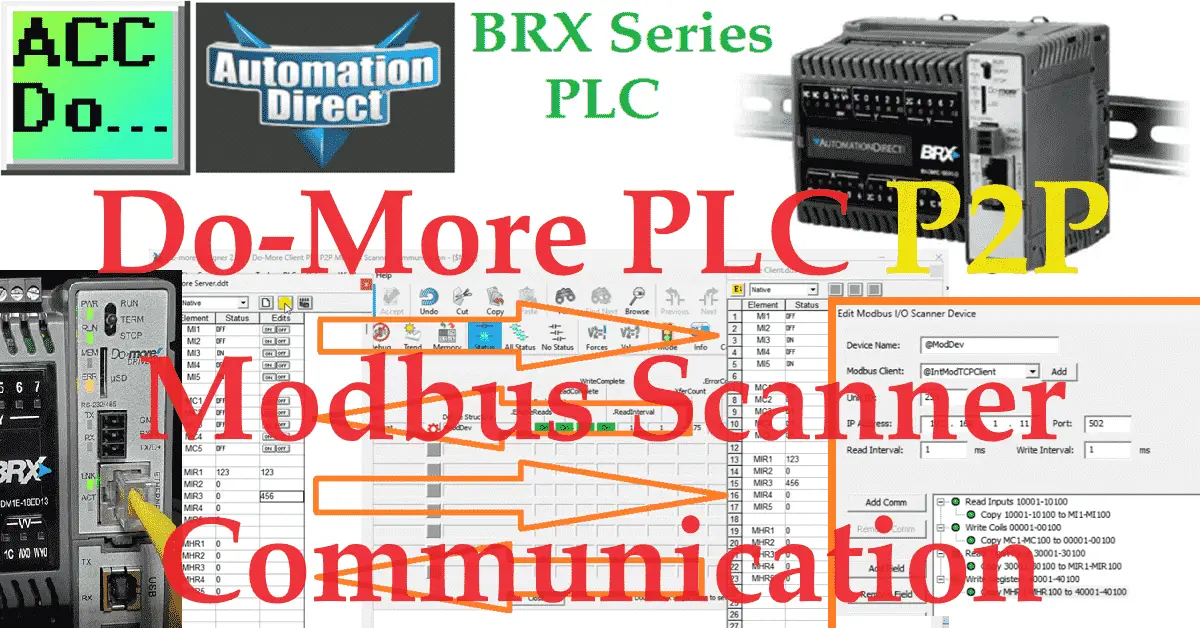

Do-More PLC P2P Modbus Scanner Communication

The Do-More PLC P2P Modbus Scanner Communication within the Do-More Designer Software offers a powerful and streamlined solution for integrating Modbus devices into your PLC system. With its advanced features and seamless integration capabilities, this Modbus Application empowers you to unlock new levels of efficiency and productivity in your industrial automation applications. A peer-to-peer (P2P) … Read more