Arduino, the leading open-source electronics platform, has recently launched a new piece of hardware called the Arduino Opta IoT PLC. The device has been designed to enable the development of advanced industrial automation solutions, making it a game-changer in the world of IoT and Industry 4.0.

In this blog post, we will look closer at the Arduino Opta IoT PLC, its features, and its benefits for industrial automation. This will be part of a series. We will now look at the Arduino Opta IoT hardware. Let’s get started.

What is Arduino Opta IoT PLC?

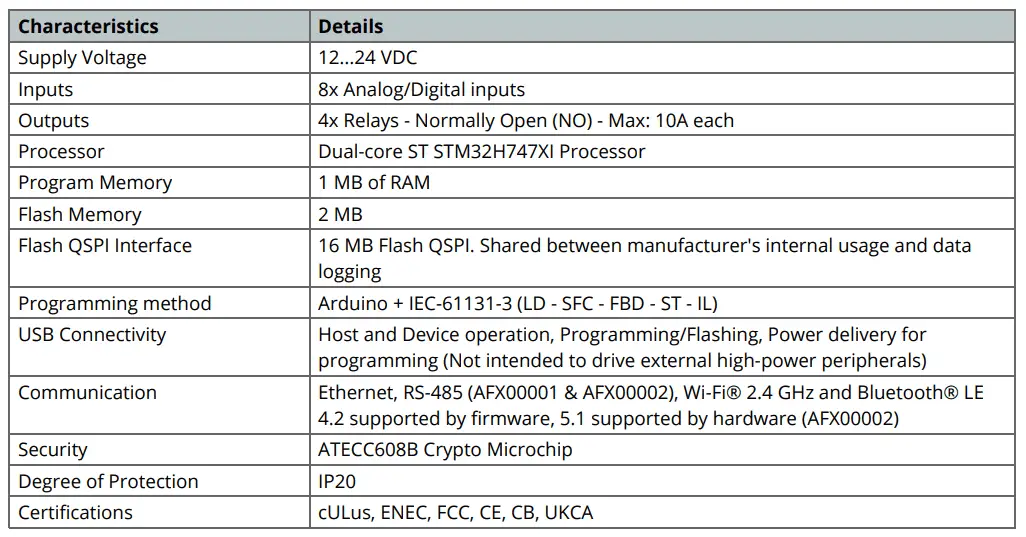

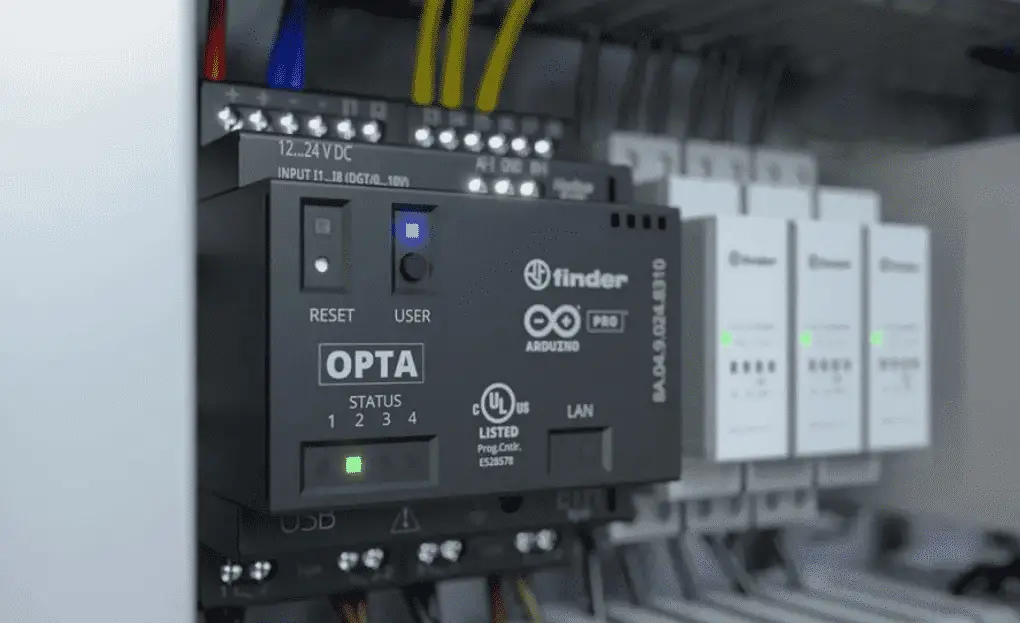

The Arduino Opta IoT PLC is a powerful and versatile piece of hardware that combines the functionality of an industrial PLC (programmable logic controller) with the flexibility of the Arduino platform. It is based on the powerful STM32H7 microcontroller, capable of delivering high-performance computing power while consuming minimal power. Finder makes this programmable logic relay (PLR) in Italy. Finder has been a global industrial automation and control component manufacturer for over 65 years. They are in the United States, Canada, and other countries. This linked webpage provides information about the company’s history, mission, and values.

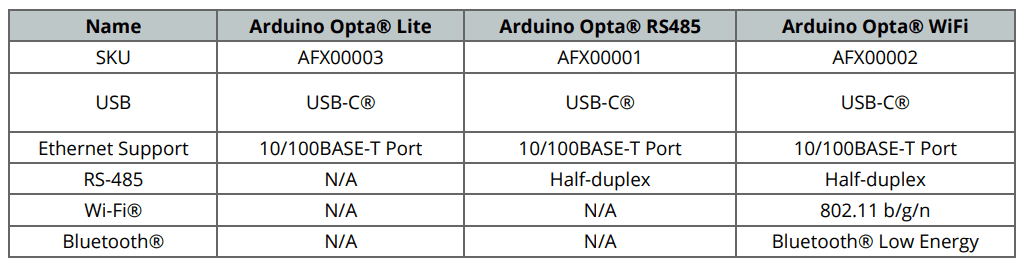

The Opta IoT PLC currently comes in three different stand-alone units. Standard features include eight digital inputs that can be used for digital or analog signals. Four relay outputs are used to control a variety of devices. An Ethernet port and USB C port are used for programming and communication. The Arduino Opta RS485 will add this serial port to the Arduino Opta Lite controller. Arduino Opta Wifi will also add Wifi and Bluetooth to the existing Arduino Opta RS485.

Future expansion will be done with the connector on the side of all three PLR controllers.

Features of Arduino Opta IoT PLC

The Arduino Opta IoT PLC has various features that make it an ideal choice for industrial automation. We have the Arduino Opta RS485 controller.

Some of these features include:

High-performance computing power – The device is based on the STM32H7 microcontroller, which delivers high-performance computing power while consuming minimal power.

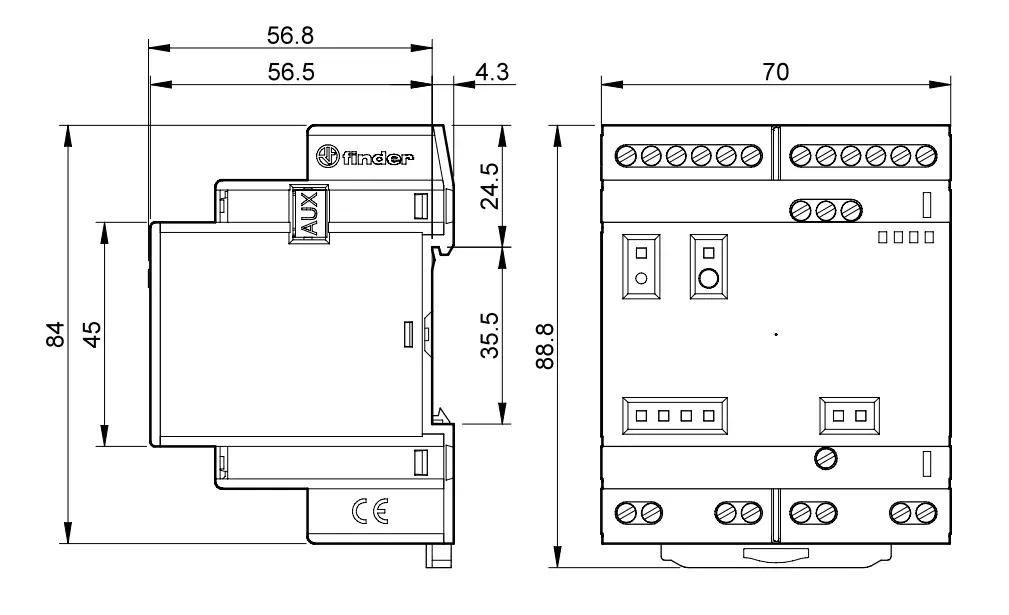

This Din rail mountable PLC measures 70 x 89 x 61 mm. It will easily fit into your new or existing control panels.

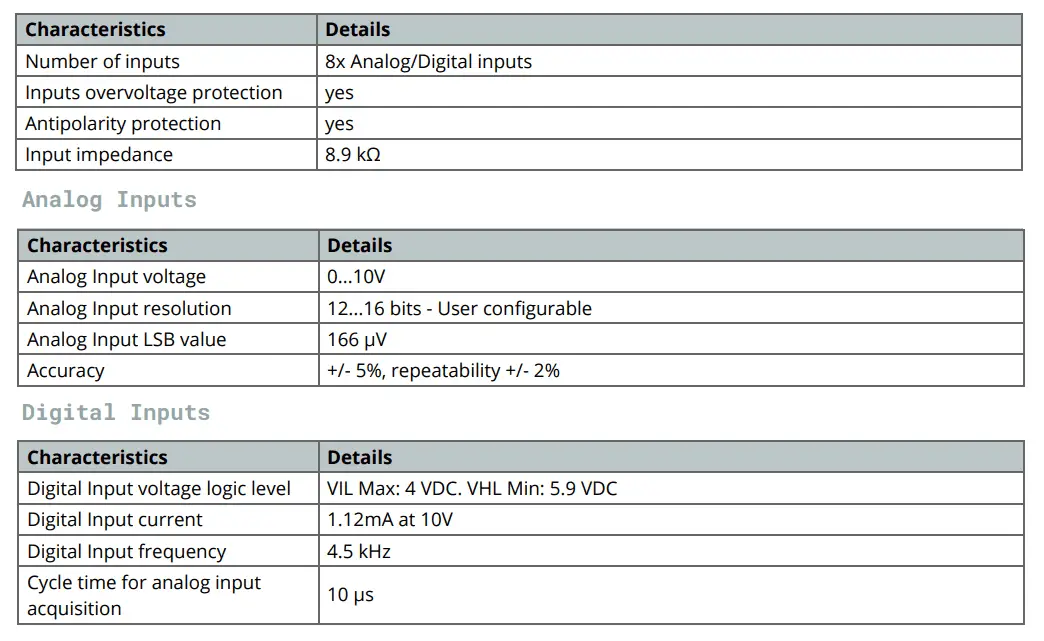

Each of the eight inputs can be analog or digital. Analog inputs accept 0 to 10 Volts DC at a 12 to 16-bit resolution. Digital inputs will be off at 4 volts DC and on at 5.9 volts DC. Standard industrial voltages of 12 or 24 Volts DC can be used for sensors. The inputs are over-voltage and polarity protected, so you do not have to worry about incorrect wiring damaging the controller.

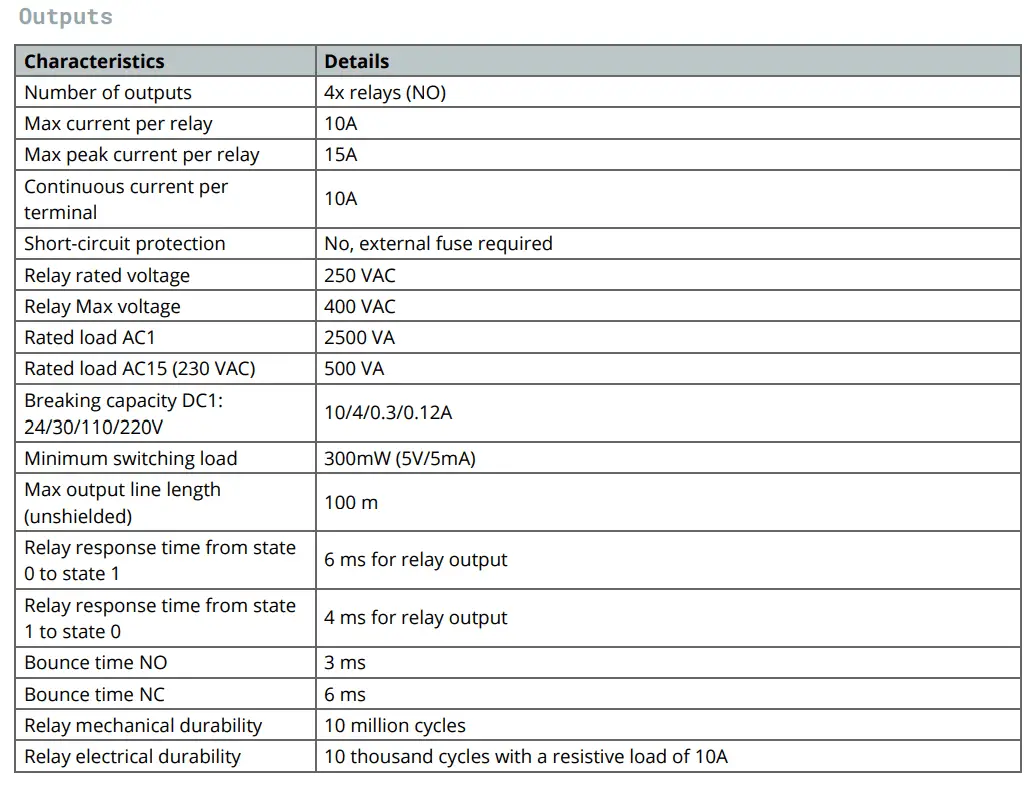

The four relay outputs normally open are rated for a maximum of 10 amps each. An external fuse is required to ensure this does not exceed 15 amps per relay. Relay durability under full load is 10,000 cycles with a 6-millisecond on and four milliseconds off delay.

A user input button is included on the programmable logic relay. This can be used as additional input to your program.

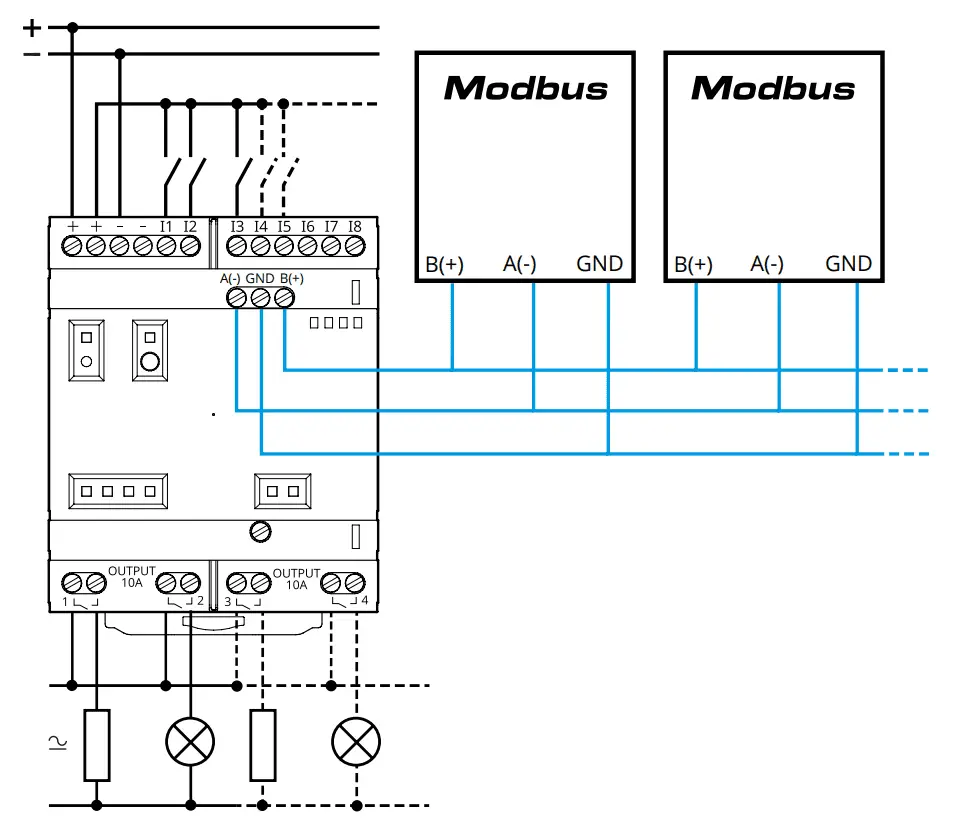

The serial RS485 can be used for Modbus communications to additional industrial equipment.

Future expandable will be done through the AUX port.

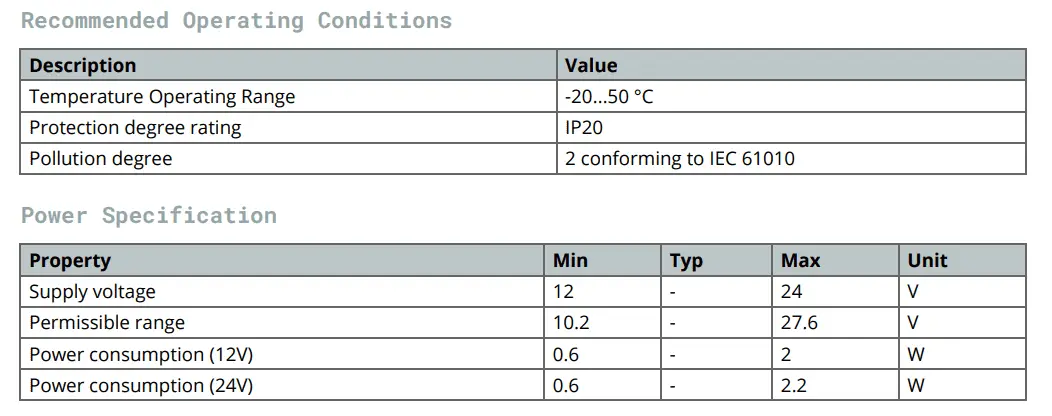

Robust design – The device has been designed to withstand harsh industrial environments, making it a reliable choice for industrial automation. Its operating temperature range is between -10 to 50 degrees Celsius.

The supply voltage to the Arduino Opta is 12 to 24 Volts DC. This can range from 10.2 to 27.6 volts of DC. The USB-C connector can power up the controller to program only. A supply voltage is required to operate the inputs and outputs.

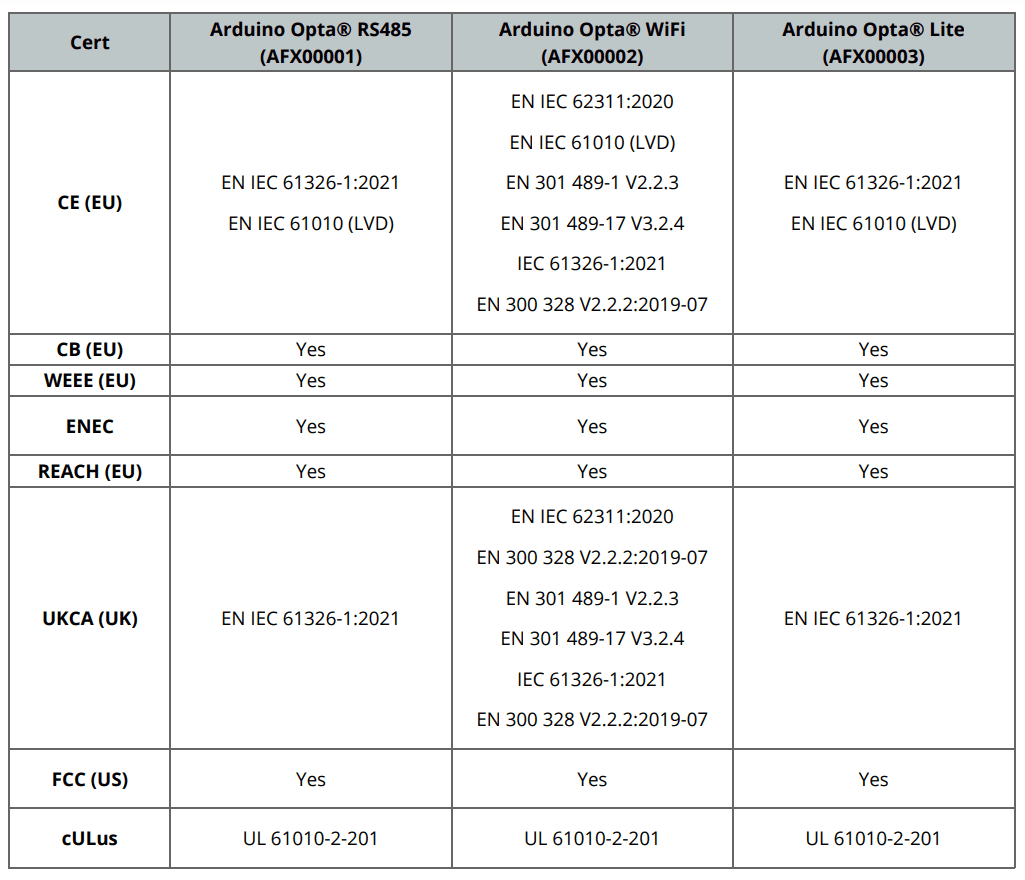

Worldwide approvals ensure you will not worry about acceptance into your new or existing control panels.

Benefits of Arduino Opta IoT PLC

The Arduino Opta IoT PLC offers a range of benefits for industrial automation, including:

Reduced development time – The device is based on the Arduino platform, which is well-known for its ease of use and simplicity. This makes it easier for developers to get started with the device and reduces development time.

Cost-effective – The device is priced competitively, making it a cost-effective solution for industrial automation.

Versatile – The device can be used for various industrial automation applications, including process control, factory automation, and machine control.

Open-source – The device is based on the open-source Arduino platform, meaning the community can contribute to its development and improvement.

The Arduino Opta IoT PLC is a powerful and versatile piece of hardware that combines an industriPLC’sC’s functionality with the Arduiplatform’sm’s flexibility. It offers a range of benefits for industrial automation, including reduced development time, cost-effectiveness, versatility, and open-source development. With its mighty computing power, I/O options, and robust design, the Opta IoT PLC is set to become a game-changer in IoT and Industry 4.0.

Watch the video below to see the unboxing and powering up of this Arduino Opta RS485 controller.

Arduino Opta PLC – IoT and Industry 4.0 Enabler

Finder OPTA 8A Series – Tutorials

Datasheet

Quickstart Sheet

Arduino Opta Hardware

Arduino PLC IDE

Arduino Software Download Page

(Arduino IDE, PLC IDE, PLC IDE Tools)

Watch on YouTube: Unlocking the Potential of Industrial Automation with Arduino Opta IoT PLC Hardware!

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.