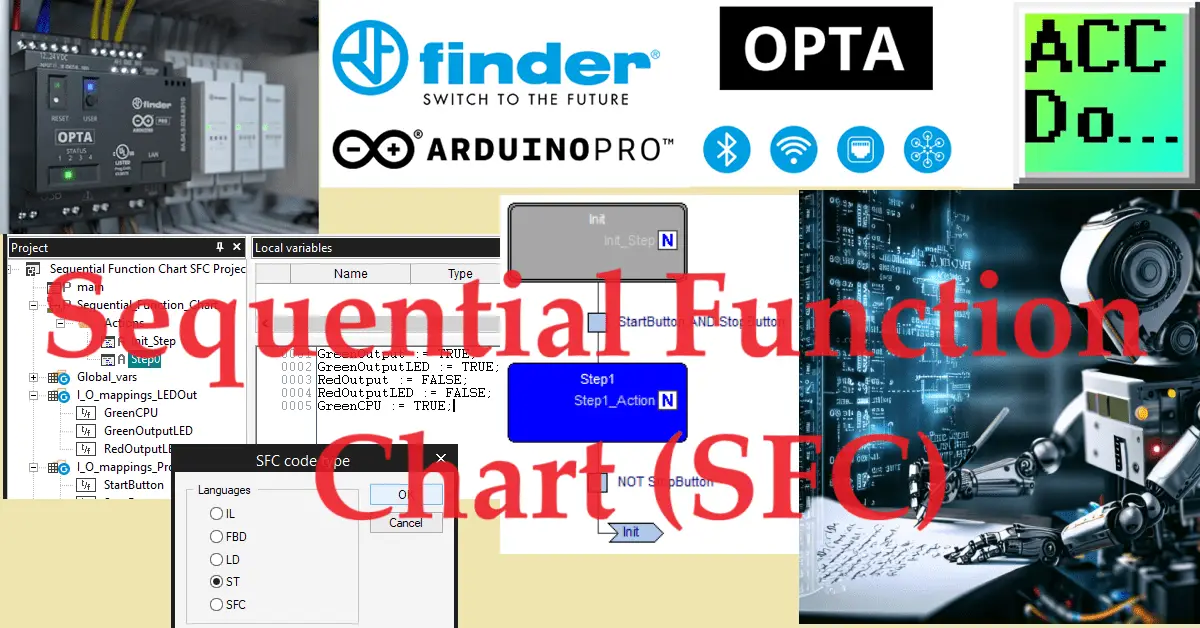

Arduino OPTA PLC – Sequential Function Chart SFC

Sequential Function Chart (SFC) is a graphical programming language that can be used in Arduino Opta PLCs. It can be used to program sequential control systems in industrial automation applications. It is a part of the IEC 61131-3 standard and is commonly used in programmable logic controllers (PLCs) and other industrial control systems. SFC allows … Read more