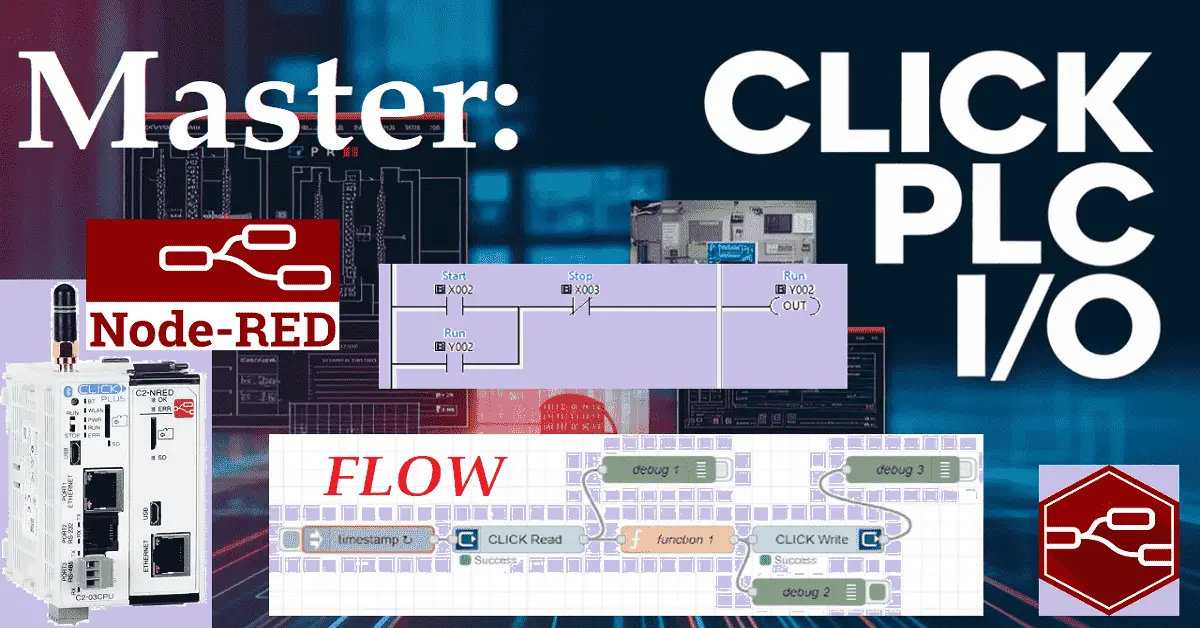

Master Node-Red C2-NRED Control of Click PLC I/O

Controlling the outputs of a PLC by observing the inputs is a fundamental concept in automation and programming. This guide will examine how the C2-NRED Node-RED module works with the Click PLC inputs and outputs. This is an exciting step into the world of automation and control systems. Imagine efficiently managing inputs and outputs using … Read more