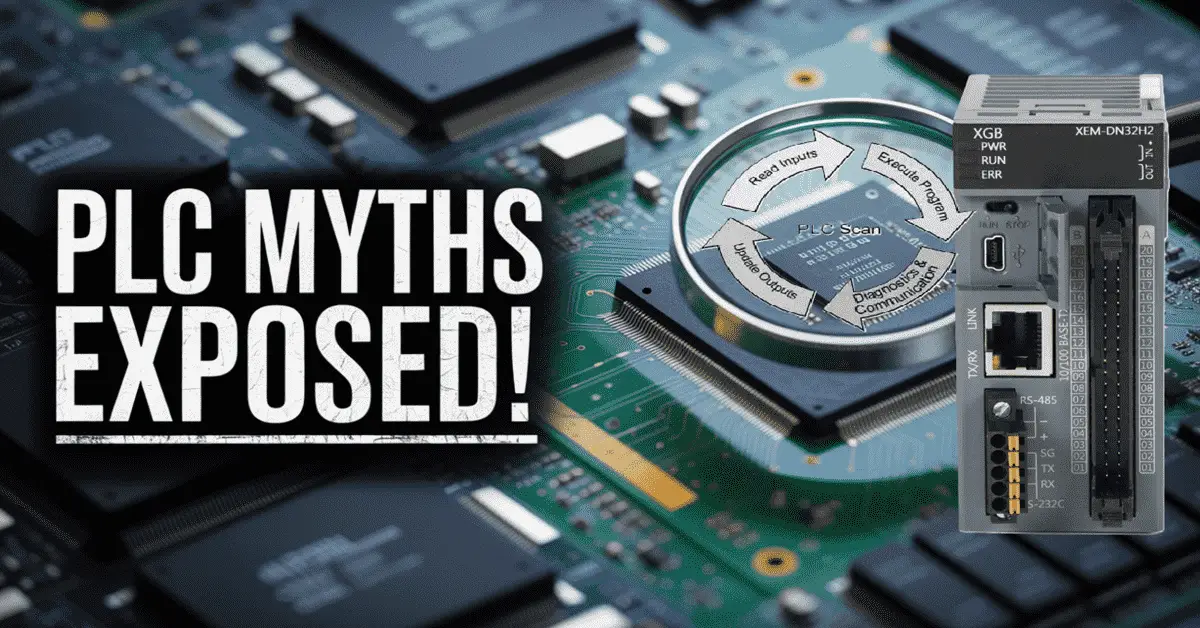

In today’s rapidly evolving world of manufacturing and automation, it’s essential to understand how Programmable Logic Controllers (PLCs) operate. However, many common misconceptions about PLCs can create confusion. We will clarify five widespread myths about PLCs, focusing on their unique functions, programming challenges, and the need for a thorough approach to their use.

By addressing these myths, we can gain a deeper understanding of how PLCs enhance efficiency and precision in modern manufacturing. Let’s explore the realities of PLCs and discover the facts that highlight their essential role in today’s industry. Continue until the end to clarify a bonus myth.

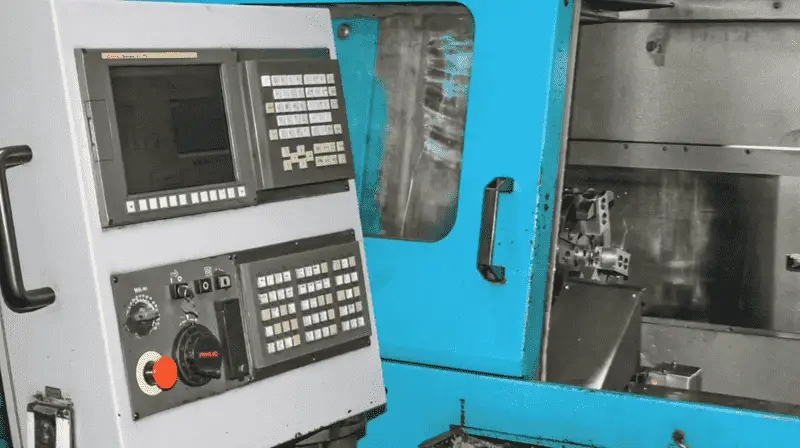

Myth 1: PLCs and CNCs are the Same

On the other hand, CNCs specialize in the meticulous control of machining tools, providing the precise management of movements required to fabricate components with exacting specifications. These systems are integral to modern machining processes, where they translate computer-aided designs into tangible products. By commanding the intricate motions of cutting, drilling, and milling tools, CNCs enable manufacturers to produce high-quality parts with remarkable accuracy, meeting the stringent demands of today’s engineering standards.

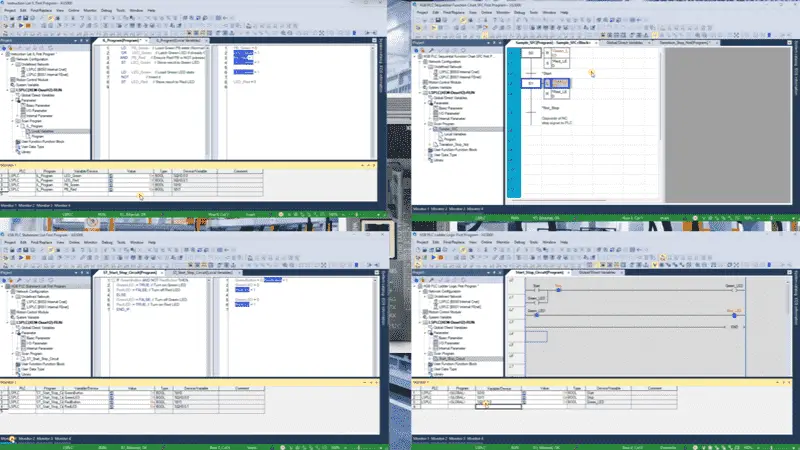

Myth 2: PLC Programming is Just Simple, Outdated Ladder Logic

These languages include Structured Text, which resembles conventional programming languages like C or Pascal; Function Block Diagram; Sequential Function Chart; and, of course, the traditional Ladder Diagram.

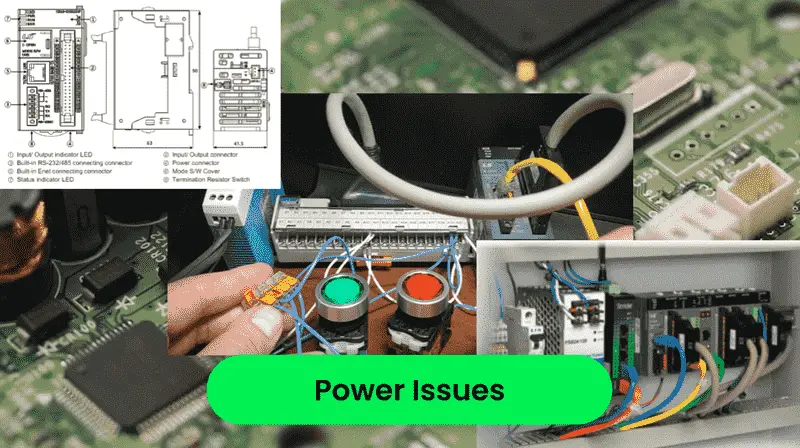

Additionally, many modern PLCs incorporate advanced functionalities that enhance their performance and versatility. Their intrinsic reliability and robust ability to function in harsh and challenging environments make PLCs indispensable across a wide range of industries.

From automotive and pharmaceuticals to food processing and energy, these versatile controllers are critical to ensuring efficient, safe, and consistent operations in diverse applications.

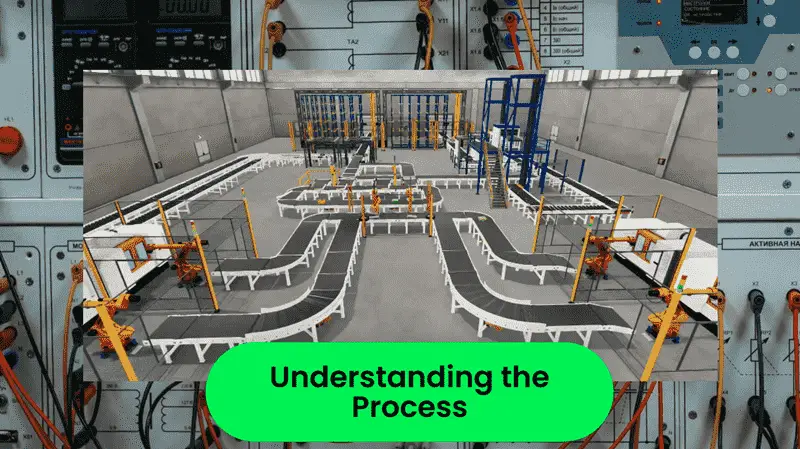

Myth 3: PLC Programming is Just About Coding

Myth 4: Debugging (Troubleshooting) is Like IT

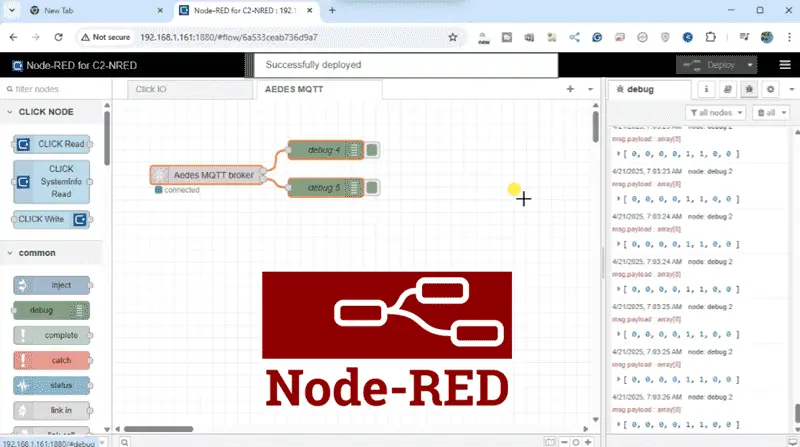

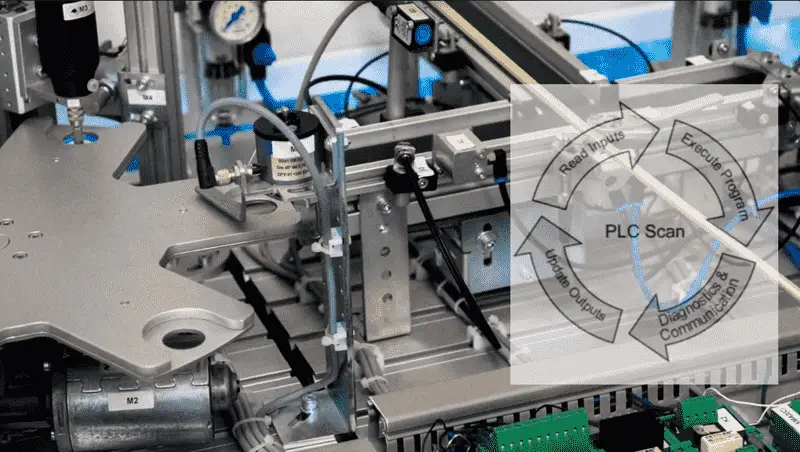

Instead of stopping the execution, debugging requires you to monitor the system while it is running. This often involves monitoring tag values in real-time, understanding how the system’s scan cycles work, and making precise adjustments to the live system. It’s essential to be cautious, as changes made during operation can affect the entire process.

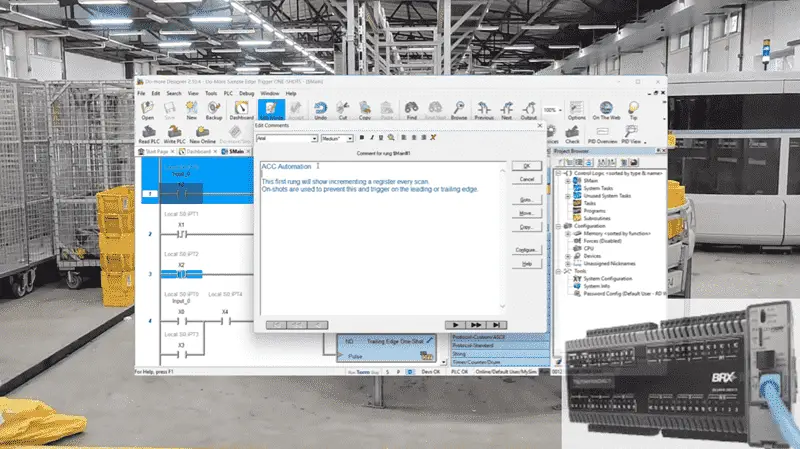

Myth 5: Naming, Comments, and Sound Coding Practices are Not Necessary in PLC Programming

This challenge becomes even more pronounced if someone else needs to work on the code or if a significant amount of time has passed since you last interacted with it. Neglecting good programming practices can lead to an increase in errors and inefficiencies. If the logic in your program is poorly structured, the likelihood of encountering bugs rises. Additionally, making updates or changes can become a cumbersome task, which slows down the entire process.

Bonus Myth: PLCs are Not Vulnerable to External Factors

PLC Beginner’s Guide to PLC Programming

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

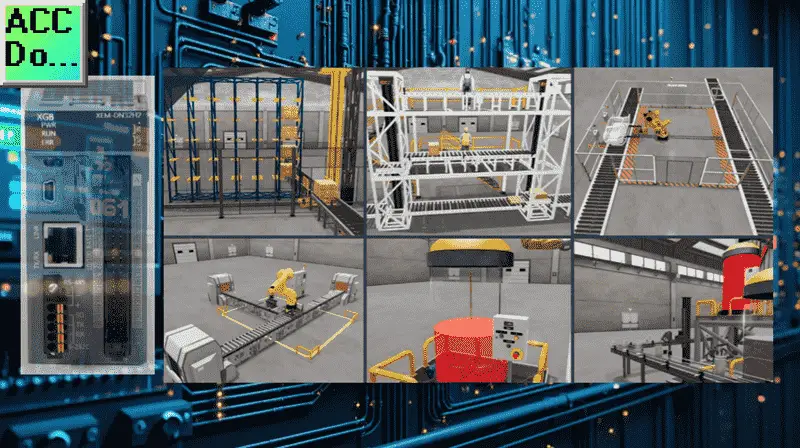

EasyPLC Software Suite is a complete PLC, HMI, and Machine Simulator Software package. See below to receive 10% off this software. This PLC learning package includes the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning package for less than $95 USD for a single computer install or less than $110 USD to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.