What is the most asked PLC Ladder Logic Question? One of the most common and foundational examples of ladder logic programming involves designing a motor start-stop circuit that utilizes latching or seal-in logic.

This specific scenario not only serves as a practical exercise but also encapsulates several critical principles of Programmable Logic Controller (PLC) programming as well as the broader realm of industrial control systems. By exploring this example, we can gain insights into circuit design, relay actuation, and the mechanisms that enable machinery to operate efficiently and safely.

Why is this question so common?

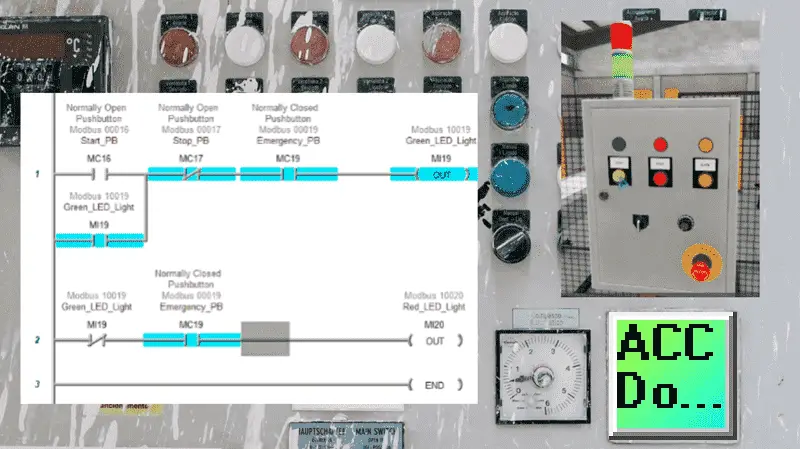

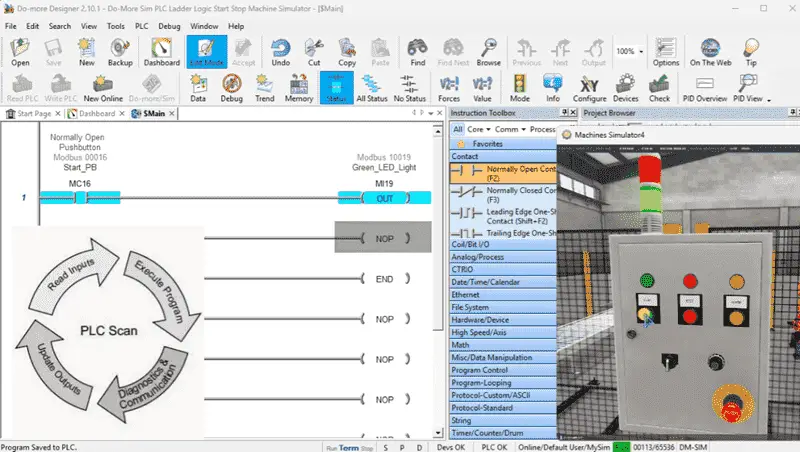

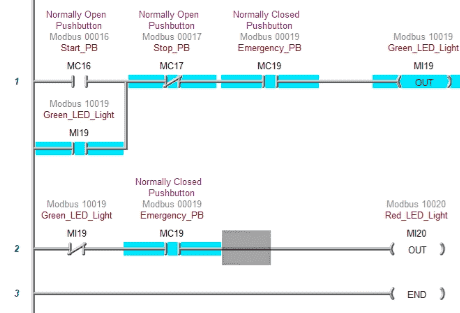

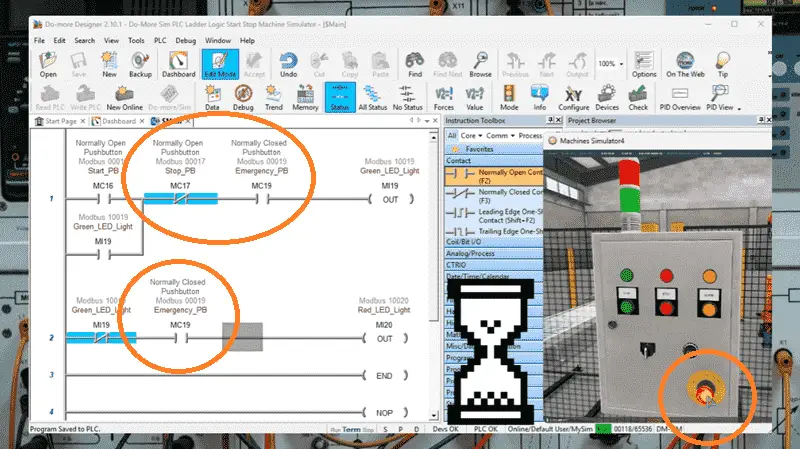

Shows the cyclical scan of the PLC. The reason that the inputs and outputs are activated or deactivated in the program is because of the PLC scan’s cyclical nature, which continuously updates the inputs and outputs.

It demonstrates basic logic, utilizing a simple combination of AND and OR operations, which are fundamental to most ladder diagrams.

Introducing latching: The “seal-in” circuit utilizes the motor’s output contact to maintain the circuit flow after the start button is released. This concept is fundamental in differentiating PLC logic from a simple momentary switch.

Tests the knowledge of contacts, requiring both normally open (for the start button and seal-in) and normally closed (for the stop and/or emergency button) contacts.

The safety component is vital: A normally closed button, which is wired in series with the start logic, serves as an essential safety feature by breaking the circuit when the button is pressed. This design also highlights the importance of “fail-safe” principles; if a wire connected to the normally closed stop button breaks, the motor will shut down automatically.

The question can be made more complex by adding additional requirements, such as including a timer, a counter, or an alarm light. Still, the fundamental start-stop circuit remains the most frequent starting point for ladder logic examples.

To see how we incorporate a jog into this circuit, Click Here. Click here to learn how you can learn PLC programming easily with the Machine Simulator by Nirtec.

Download this Do-More Start Stop Ladder Logic here.

Watch on YouTube: Why Every Beginner Needs a PLC Simulator Now!

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. See below to receive 10% off this software. This PLC learning package consists of the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning package for less than $95 USD for a single computer installation or less than $110 USD for multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.