Now You Can Have Robust Data Logging for Free – Part 1

Now You Can Have Robust Data Logging for Free – Part 2

Now You Can Have Robust Data Logging for Free – Part 3

Now You Can Have Robust Data Logging for Free – Part 4

PLC program – Continue

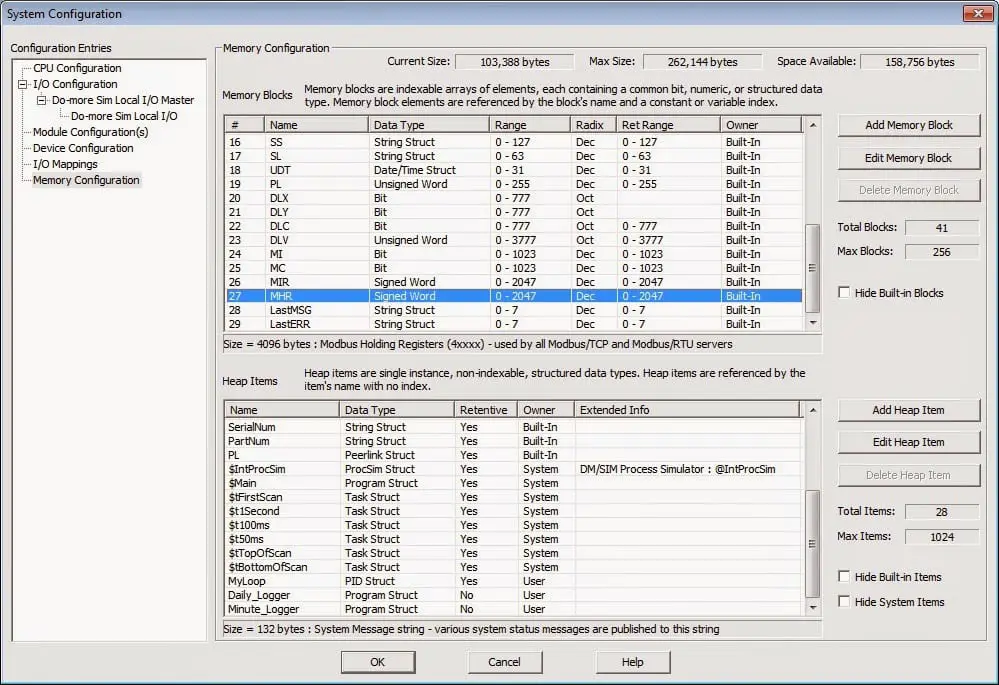

This is where the amount of memory used in the controller can be significant. The Do-More PLC will allow you to allot more memory to areas in the configuration menu.

We will leave this at the default setting in our project. Remember that this can be modified any time if you wish to increase the amount of information logged.

Run Minute_Logger

MHR2 – Pointer – Value 670 to 2000

MHR660 – MHR669 – Current logged values

MHR660 – Year – xxxx MHR661 – Month – xx MHR662- Day – xx

MHR663 – Hour – xx MHR664 – Minute – xx MHR665- Second – xx

MHR666 – MHR667 – Current Meters – xxxxxxxx

MHR668 – Current Rate – xxxxx mpm

Internally used bits –

D40 – D49 / V2

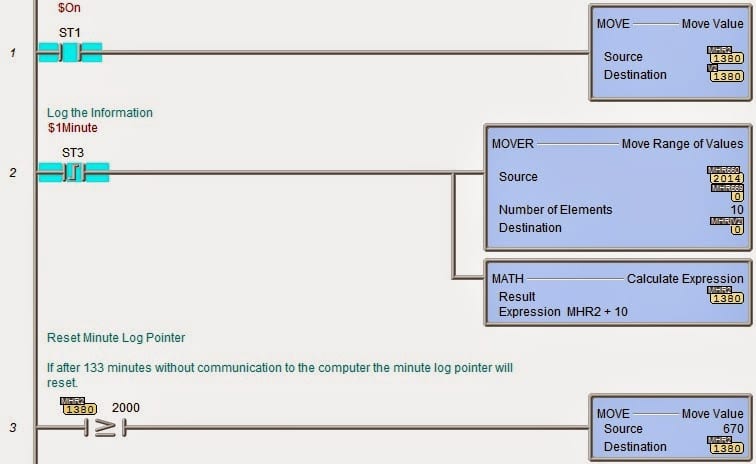

We will start by looking at the log pointer.

Minute Log Pointer

MHR2 is the pointer for the minute production log. It will point to the location to store the next series. (Next Minute of Data)

MHR2 = 670 means that we are all data has been retrieved.

MHR2 = 2000 means that we have 133 minutes of data to be retrieved.

A visual basic program will read MHR2. If it is more significant than 670 then the data will be read and then written into a database. It will then write the value of 670 back into MHR2 to reset the pointer.

Current values are located here:

MHR660 – MHR667

After 133 minutes (~2 hours) without communication with the programmable logic controller, the data will be lost. You may wish to increase the memory area as mentioned above. This will change the MHR area, so your reset value will have to change from 2000 to your new setting.

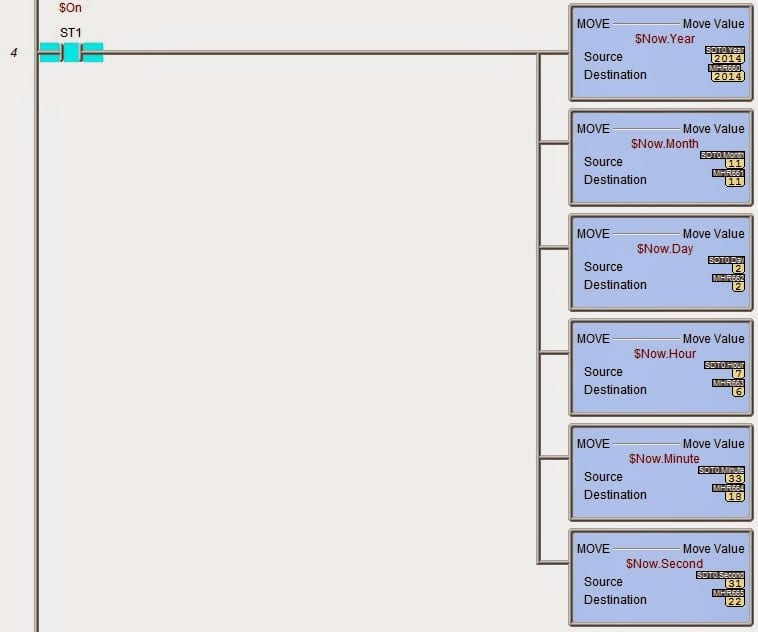

Log Time Parameters

MHR660 – Year

MHR661 – Month

MHR662 – Day

MHR663 – Hour

MHR664 – Minute

MHR665 – Second

This area sets up the real-time clock. (RTC) The format is as follows: YYYY MM dd hh mm ss.

Meters

For testing purposes, a 50ms internal timer is used. The count input should be activated on the leading edge if you remove the 50ms internal timer.

With each pulse of the input, D40 increments by 303. There after ten pulses, the value in D40 will be 3030. This would represent 3.030 meters of product.

To change this into an integer to log the data, we will divide D40 by 1000 and store the result in D41.

D41 will now contain the total meters for the shift. This is a 32-bit address location, and we want the results to be in a 16-bit address location. (D vs. MHR)

Using some math, we split our total meters into the most significant four digits and the least significant four digits.

MHR666 – MHR667 – Current Meters – xxxxxxxx

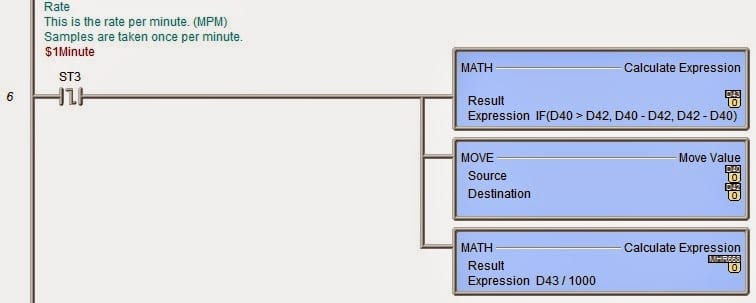

Rate

This is the rate per minute. (MPM)

Samples are taken once per minute.

D40 – Current Meters

D42 – Last Minutes Meters

D43 – Meters passed since the last minute

MHR668 – Meters per minute (Rate)

If the current meters are more significant than the last minute meters, then subtract the previous minute meters from the current meters and store them in the meters passed since the last minute. If not, do the opposite. This will ensure that a negative number is not obtained. The meters passed since the last minute are then divided by 1000, so we are only looking at the integer of the number.

This finishes the PLC programming. In part 5, we will continue getting the information out of the PLC.

If you have any questions or need further information, please get in touch with me.

Regards,

Garry

To get a copy of the entire program. Please get in touch with me in the contact section. I will be more than happy to send you the program. Put ‘Robust Logger’ in the subject line.

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.