PLC programming for beginners can seem intimidating, but it doesn’t have to be. With the right resources, anyone can get up and running quickly. Here are the 17 most common frequent questions answered. This is a great place to start for anyone learning about PLC programming. Through thorough explanations of key concepts and answers to many of the most common questions about PLC programming, this resource should give you all the information you need to take your first steps into PLC programming.

We will discuss the common questions for PLC programming using several different manufacturers of PLC hardware and software. Ultimately, you will see my recommendation for a beginner learning industrial automation. Let’s get started.

1 – What is a PLC?

A PLC (Programmable Logic Controller) is a digital computer for industrial automation. It is designed to operate in harsh environments and can control machinery and processes in manufacturing plants, power generation, and other industries.

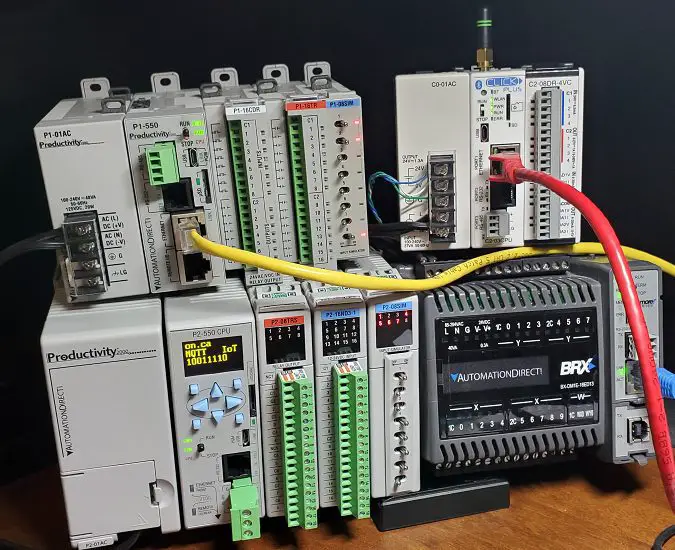

2 – What are the types of PLC?

The main types of PLCs are compact, modular, and rack-mounted. Compact PLCs are also known as shoe boxes. They have all the components integrated into one unit. Modular PLCs are built with interchangeable parts. These components usually are attached to the side of the main PLC unit. Rack-mounted PLCs are designed to be mounted in a cabinet or rack. These PLCs generally have a more significant number of inputs and outputs. The rack contains the communication bus and power system. Components or cards will fit into the rack.

Note: PLCs now come in many configurations. Refer to your operation manual for the components and expansion of your controller.

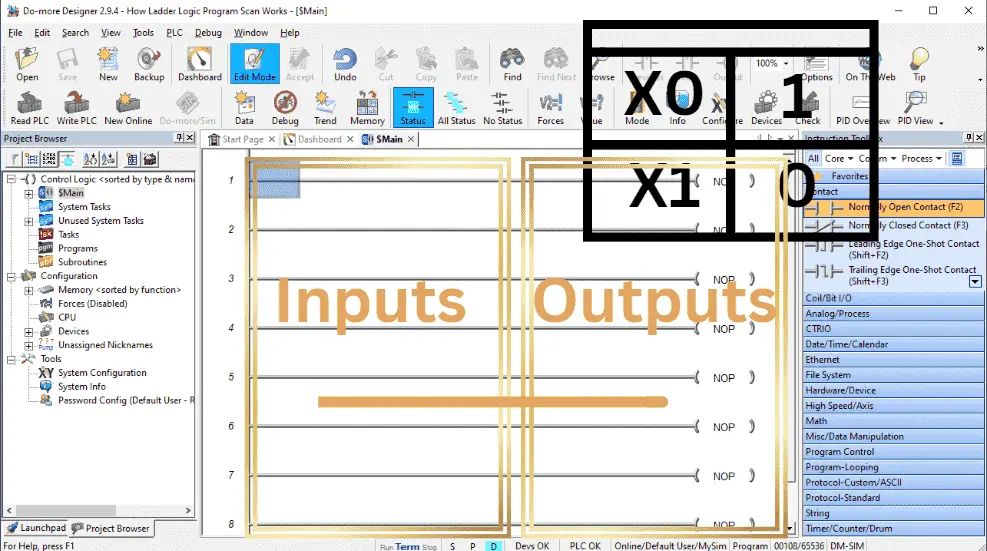

3 – What is ladder logic?

Ladder logic is the most common programming language used to program PLCs. It is a graphical representation of electrical wiring diagrams used to describe and control complex industrial systems. It is called a ladder because the visual image resembles a ladder with rungs.

Ladder logic is solved from left to right, top to bottom. The outputs from the previous rung are available for the next rung to use.

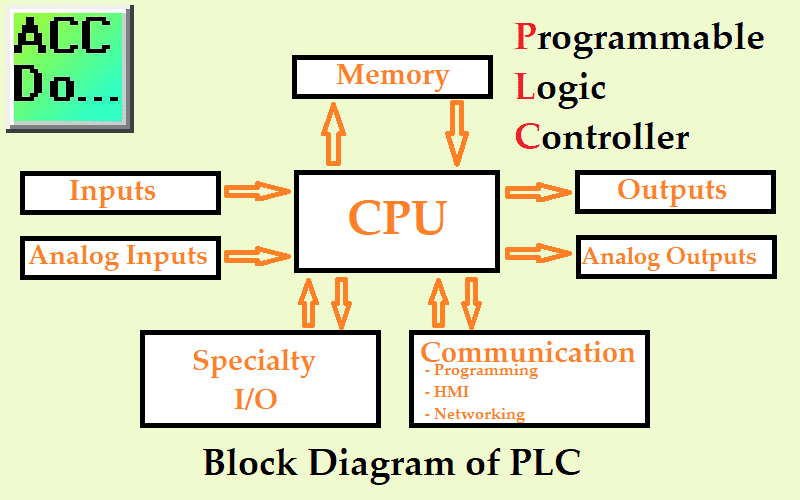

4 – What are the basic components of a PLC system?

The basic components of a PLC system are the CPU (central processing unit), power supply, input/output (I/O) modules, and programming device.

https://accautomation.ca/the-7-essential-parts-of-a-plc-system/

Although these are the basic components, we usually add HMI (Human Machine Interface) and networking today. As part of the IoT (Internet of Things) or Factory 4.0, PLCs are just another edge device on your network.

5 – What are the different types of programming languages used in PLCs?

The IEC 61131-3 standard lists five programming languages to program your PLC. They are a ladder diagram (LD), a function block diagram (FBD), structured text (ST), a sequential function chart (SFC), and an instruction list (IL).

https://accautomation.ca/what-everybody-ought-to-know-about-plc-programming-languages/

Even though there are five official languages you can use, not all PLC controllers use every language. Please refer to your controller’s operation manual.

6 – What is the function of the CPU in a PLC?

The CPU (Central Processing Unit) is the brain of the PLC. It executes your program and controls the I/O modules to process the inputs and outputs.

7 – What is the role of the power supply in a PLC?

The power supply provides the necessary electrical power to the PLC system. MTBF (Mean Time Before Failure) is usually calculated on the life expectancy of the power supply.

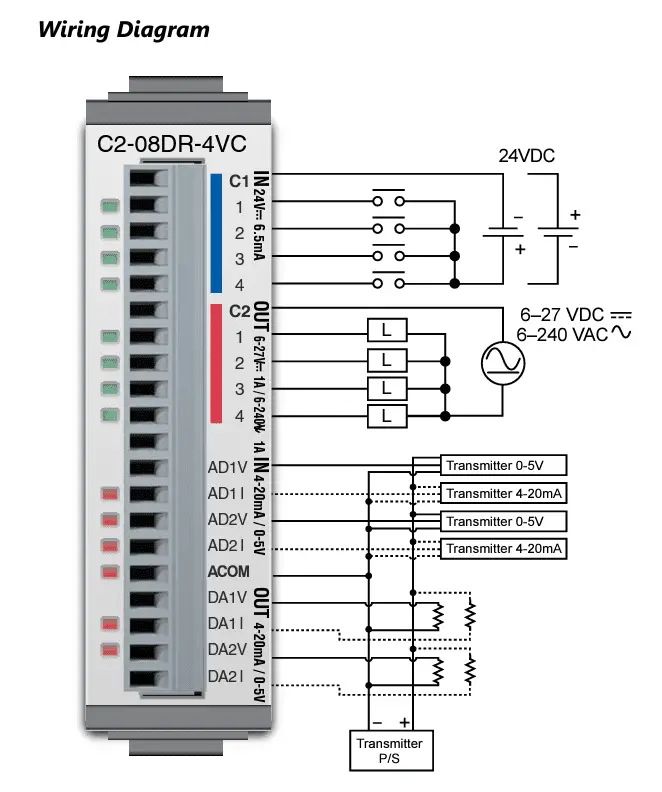

8 – What are I/O modules?

I/O modules allow the PLC to communicate with the outside world. They convert analog and digital signals into a format the PLC can process.

9 – What is the difference between analog and digital I/O?

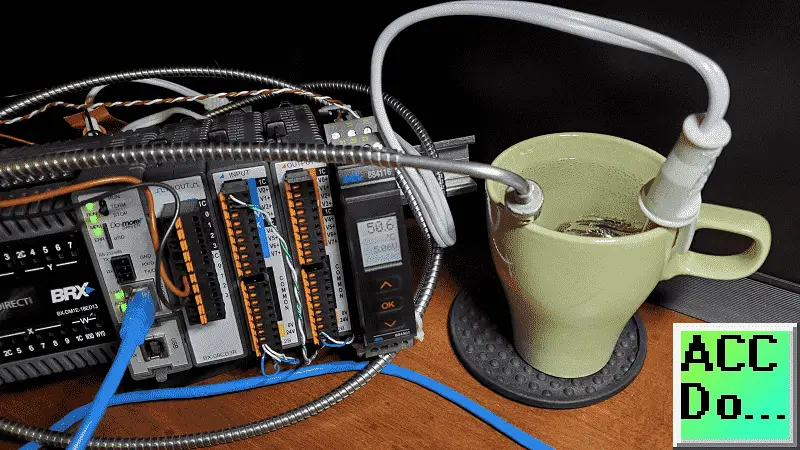

Analog I/O deals with continuous signals with values like temperature, pressure, flow, etc. Digital I/O deals with discrete signals with only two possible values, on or off.

10 – How do you program a PLC?

You can program a PLC using software designed for this purpose. Typically, every manufacturer will have their proprietary programming software package. The software allows you to create a program using the language or languages of your controller. Once you have completed the program, you can download it to the PLC.

Software prices range from free to thousands of dollars. They can even include maintenance fees for your programming software.

This website has promoted many minimum investment or free programming software. The following two even come with built-in simulators, so you can program and test without purchasing hardware.

https://accautomation.ca/productivity-suite-plc-simulator-software-free-download/

https://accautomation.ca/learn-plc-programming-free-now-video/

11 – What are the advantages of using a PLC over traditional relay-based control systems?

PLCs are more reliable, easier to troubleshoot and provide more flexibility in programming than traditional relay-based control systems.

12 – What is the difference between open-loop and closed-loop control systems?

Open-loop control systems do not use feedback, while closed-loop control systems use feedback to adjust the system’s output.

13 – What is a PID controller?

A PID (proportional-integral-derivative) controller is a closed-loop control system used to maintain a desired output in response to changing input. It calculates and adjusts the output using three parameters (proportional, integral, and derivative). This is a time-based control system with fixed parameters.

14 – What is the function of a watchdog timer in a PLC?

A watchdog timer is a safety feature that monitors the operation of the PLC. If the timer expires, it indicates a fault in the system, and the PLC will enter safe mode.

https://accautomation.ca/productivity-open-p1am-industrial-arduino-watchdog-timer/

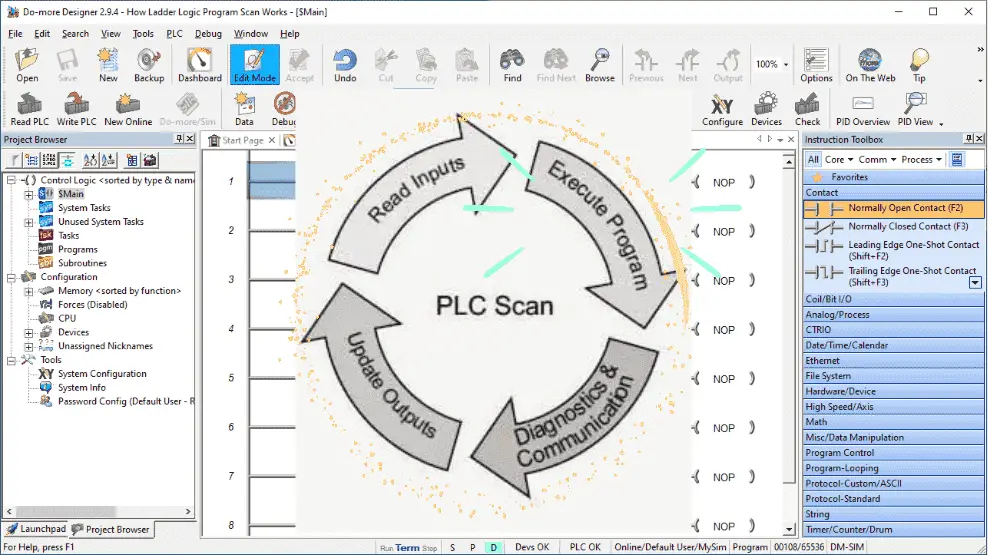

15 – What is a scan cycle?

A scan cycle is a time for the CPU to execute the program once. It consists of four phases: input read scan, execute program scan, diagnostics, communication, and update output scan.

https://accautomation.ca/who-else-wants-to-know-how-a-plc-scans/

16 – What is the difference between a local and remote I/O module?

A local I/O module is physically connected to the PLC, while a remote I/O module is connected to the PLC over a communication network. Remote I/O communication is deterministic. This means the communication time is known for the I/O to respond quickly. Remote I/O will usually involve a proprietary communication protocol based on the manufacturer.

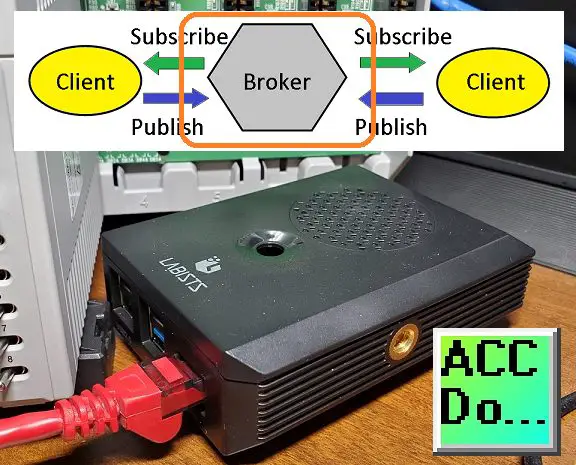

17 – What is network communication in a PLC system?

Network communication is the data exchange between different devices in a PLC system over a communication network. This is usually done with open communication protocols like Modbus or Ethernet/IP.

https://accautomation.ca/series/node-red-iot-enabling-software/

Node-Red is an open-source program that enables you to collect, store and display data from your controllers. This is an IoT-enabling software package.

So how do you start and begin PLC programming? The answer will differ from user to user, but I would start with the PLC beginners guide. This provides articles that can be followed from start to finish or quickly scanned for the topic you are looking for answers to.

If you have a specific question on your PLC hardware, then Search Threads can help. This custom google search will only list matches from select, highly-rated websites and communities.

Watch below to see the 17 FAQs for PLC programming.

Free learning and training series for PLCs.

Productivity Series

P1000

P2000

BRX Do-More

Click / Click PLUS (Koyo)

Omron CP1H Series

Horner XL4 Series

EasyPLC Software Suite – 3D training package

Purchase your copy of this learning package for less than USD 75 for a single computer install or less than USD 100 to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/

Learn PLC programming the easy way. Invest in yourself today.

C-More EA9 Series of HMI

(Webserver, FTP, Data Logging, Free Remote Apps, etc.)

Node-Red is a free IoT software hub that can communicate MQTT and many standard industrial protocols. This series will help you communicate to the PLC, create an HMI on any electronic device, log data to a database, and view the information on a spreadsheet for analysis.

Node-RED IoT enabling software

Watch on YouTube: PLC Programming for Beginners: 17 Common Questions Answered!

If you have any questions or need further information, please get in touch with me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.