The Productivity 2000 series of programmable logic controllers has a slim DIN rail density form factor. This means that this micro-modular PLC can have a power supply, CPU, and seven IO modules in only 10-1/2 inches. Input and output cards can be installed, removed, or replaced without turning the power off to the PLC system. (Hot-swappable) This means that your system can remain running while troubleshooting your system hardware. The Productivity 2000 hardware supports up to 240 local I/O for discrete, analog, and motion applications with a high-performance CPU equipped with five communications ports and 29 discrete and analog I/O modules. Several remote IO options are available on this award-winning PLC in the Productivity series family.

Productivity 1000 (Stackable Micro PLC)

Productivity 1000 (Stackable Micro PLC)

Productivity 2000 (Micro Modular Programmable Controller)

Productivity 3000 (Modular Programmable Controller)

These three series by FACTS engineering currently make up the Productivity Series PLC from Automation Direct.

We will be looking at the features of the powerful P2000 controller. Let’s start by looking at the P2000 hardware.

Productivity 2000 Series PLC System Hardware

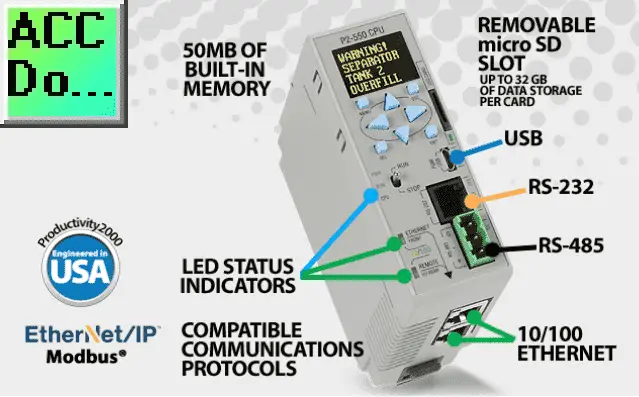

CPU – Central Processing Unit

The P2-550 CPU module has 50 M bytes of user memory. This means that you have plenty of room for your program and information. A real-time clock/calendar (RTC) is incorporated within the CPU. The 4 x 10 character OLED display can display system status or you can program this to display your own messages. This is ideal for troubleshooting a program. A built-in MicroSD card slot can be used for program transfers and data logging.

The P2-550 CPU module has 50 M bytes of user memory. This means that you have plenty of room for your program and information. A real-time clock/calendar (RTC) is incorporated within the CPU. The 4 x 10 character OLED display can display system status or you can program this to display your own messages. This is ideal for troubleshooting a program. A built-in MicroSD card slot can be used for program transfers and data logging.

The Productivity 2000 CPU offers 5 communications ports.

- RS-232 (RJ12) port with Modbus RTU Master/Slave and ASCII In/out protocols at up to 115.2 k baud

- RS-485 (3-wire terminal block) port with Modbus RTU Master/Slave and ASCII In/out protocols at up to 115.2 k baud

- Ethernet (RJ45) port with EtherNet/IP Scanner/Adapters, Modbus TCP, programming and monitoring protocol(s) at 10/100 Mbps

- Ethernet (RJ45) remote I/O port for P1-RS or P1-RX remote I/O expansion, GS drives, Protos X field I/O and PS-AMC motion controllers

- MicroB-USB port with programming and monitoring protocol(s)

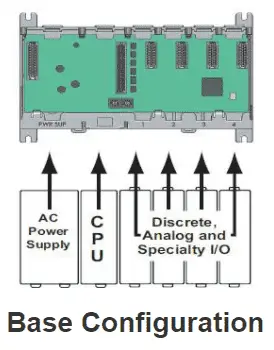

Productivity 2000 Hardware Bases

The Productivity 2000 hardware IO bases come in different sizes to accommodate 4, 7, 11, or 15 I/O modules. Any I/O module may be installed in any I/O slot. There are no power supply budgets or module type restrictions on the placement. The base holds the power supply, CPU, and IO modules. (IO Cards) The base can be DIN rail or flush-mounted in your control panel. All discrete and analog modules can be software-enabled for Hot Swap operation.

The Productivity 2000 hardware IO bases come in different sizes to accommodate 4, 7, 11, or 15 I/O modules. Any I/O module may be installed in any I/O slot. There are no power supply budgets or module type restrictions on the placement. The base holds the power supply, CPU, and IO modules. (IO Cards) The base can be DIN rail or flush-mounted in your control panel. All discrete and analog modules can be software-enabled for Hot Swap operation.

Productivity 2000 Hardware – Power Supplies

Snapping into the left-most socket of the Productivity 2000 base, the power supply comes in your choice of three different external supply voltages. (100-240 VAC, 12-24 VDC or 24 VAC, 24-48 VDC) The power supply(PS) supplies 24 VDC and 3.3 VDC to the base. It has enough power so you can place any combination of IO cards without needing to worry about the location or power budget.

Snapping into the left-most socket of the Productivity 2000 base, the power supply comes in your choice of three different external supply voltages. (100-240 VAC, 12-24 VDC or 24 VAC, 24-48 VDC) The power supply(PS) supplies 24 VDC and 3.3 VDC to the base. It has enough power so you can place any combination of IO cards without needing to worry about the location or power budget.

P2000 DC I/O Hardware

A variety of 8-point, 15-point, 16-point, and 32-point sinking or sourcing discrete I/O modules are available. Isolated commons and I/O status indicators are provided on each module. Choose from three wiring options: screw, spring terminal blocks, or ZIPLink pre-wired cables and connection modules

A variety of 8-point, 15-point, 16-point, and 32-point sinking or sourcing discrete I/O modules are available. Isolated commons and I/O status indicators are provided on each module. Choose from three wiring options: screw, spring terminal blocks, or ZIPLink pre-wired cables and connection modules

P2000 AC I/O Hardware

8 and 16-point AC input and output modules, and 8 and 16-point relay output modules are available. Choose from three wiring options: screw, spring terminal blocks, or ZIPLink pre-wired cables and connection modules.

8 and 16-point AC input and output modules, and 8 and 16-point relay output modules are available. Choose from three wiring options: screw, spring terminal blocks, or ZIPLink pre-wired cables and connection modules.

P2000 Analog I/O Hardware

Analog modules incorporate displays that make wiring, programming, and troubleshooting easier. 4, 8, and 16-channel analog I/O modules;

Analog modules incorporate displays that make wiring, programming, and troubleshooting easier. 4, 8, and 16-channel analog I/O modules;

8-channel combination analog I/O modules,

9-8-channel thermocouple,

10-6-channel RTD modules,

8-channel thermistor module.

Choose from three wiring options: screw, spring terminal blocks, or ZIPLink pre-wired cables and connection modules.

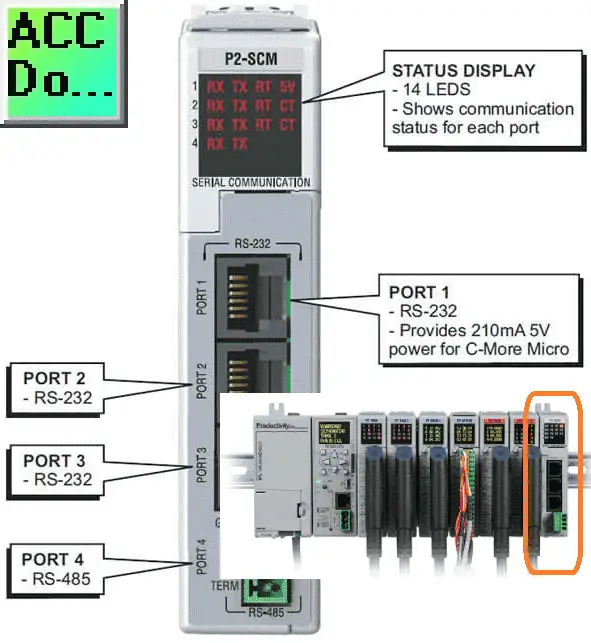

P2000 P2-SCM 4-port Serial Card

The communication module allows the connection of a wide range of serial devices, such as barcode scanners, scales, printers, modems, etc. There are three RS-232 (RJ12) ports and one RS-485 (4-wire terminal block) port. The LED status display shows the communication status of each port.

The communication module allows the connection of a wide range of serial devices, such as barcode scanners, scales, printers, modems, etc. There are three RS-232 (RJ12) ports and one RS-485 (4-wire terminal block) port. The LED status display shows the communication status of each port.

All ports support Modbus RTU Master/Slave, ASCII IN/OUT, and custom protocols at up to 38.4 k baud. Port 1 can supply power to C-more Micro panels so no external power supply is required.

Remote IO Hardware Expansion Capabilities

The productivity 2000 can be expanded in two different ways:

P2-RS Remote I/O Expansion Module

This productivity 2000 remote expansion has the following features:

This productivity 2000 remote expansion has the following features:

- (1) RJ45 Ethernet Remote I/O port

- (1) RS-232 (RJ12) port with Modbus RTU Master/Slave and ASCII In/out protocol(s)

- (1) RS-485 (3-wire terminal block) port with Modbus RTU Master/Slave and ASCII In/out protocol(s)

- (1) Micro USB IN (type B) port for remote CPU programming and monitoring

- 4 line x 10 characters backlit OLED display

- Up to 8 Remote Slaves can be connected to a single CPU for a remote I/O network

P1-RX Remote I/O Expansion Module

Adds low-cost Productivity1000 I/O to the P2-550 CPU. This module adds (1) Ethernet (RJ45) port for use with P2-550 CPU remote. You can add up to 8 P1-RX remote bases to a single P2-550 CPU.

Adds low-cost Productivity1000 I/O to the P2-550 CPU. This module adds (1) Ethernet (RJ45) port for use with P2-550 CPU remote. You can add up to 8 P1-RX remote bases to a single P2-550 CPU.

More information on the Productivity 1000 Series can be found here.

Productivity 2000 Features (P2000)

- CPU with 5 communication ports

- OLED message display on the CPU module

- Plenty of discrete and analog I/O modules

- Status displays on all discrete I/O modules

- OLED data display on analog modules

- P2-RS remote I/O expansion module, or use the Productivity1000 P1-RX remote expansion module to add even lower-cost remote I/O to your system

- FREE full-featured Productivity Suite software

- Programming with several ports – USB, Ethernet, Serial

- Hardware auto-discovery

- Hot-swappable I/O

- Choose from three wiring options

- Slim DIN rail density form factor:

- hardware – power supply, CPU, and seven modules in only 10-1/2 inches

- All project files (program, tag name database, and all the program documentation) in the CPU

- Run-time editing and debug mode on CPU

- Easy data logging with micro SD on CPU

- Secure Web server to access data files and system tags

- Easy drive and motion controller integration

- Coordinate motion control with PS-AMC allows control of up to 16 axes and synchronization of up to 4 axes

- Two-Year Warranty

Productivity 2000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Overview (Features of the fully functional free software package for the Productivity Family of PLC (PAC) controllers)

Productivity Suite Programming Software (Free Download Link)

This software contains all of the instructions and helps files for the Productivity Series.

Watch on YouTube: Productivity 2000 Series PLC P2000 Hardware

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.