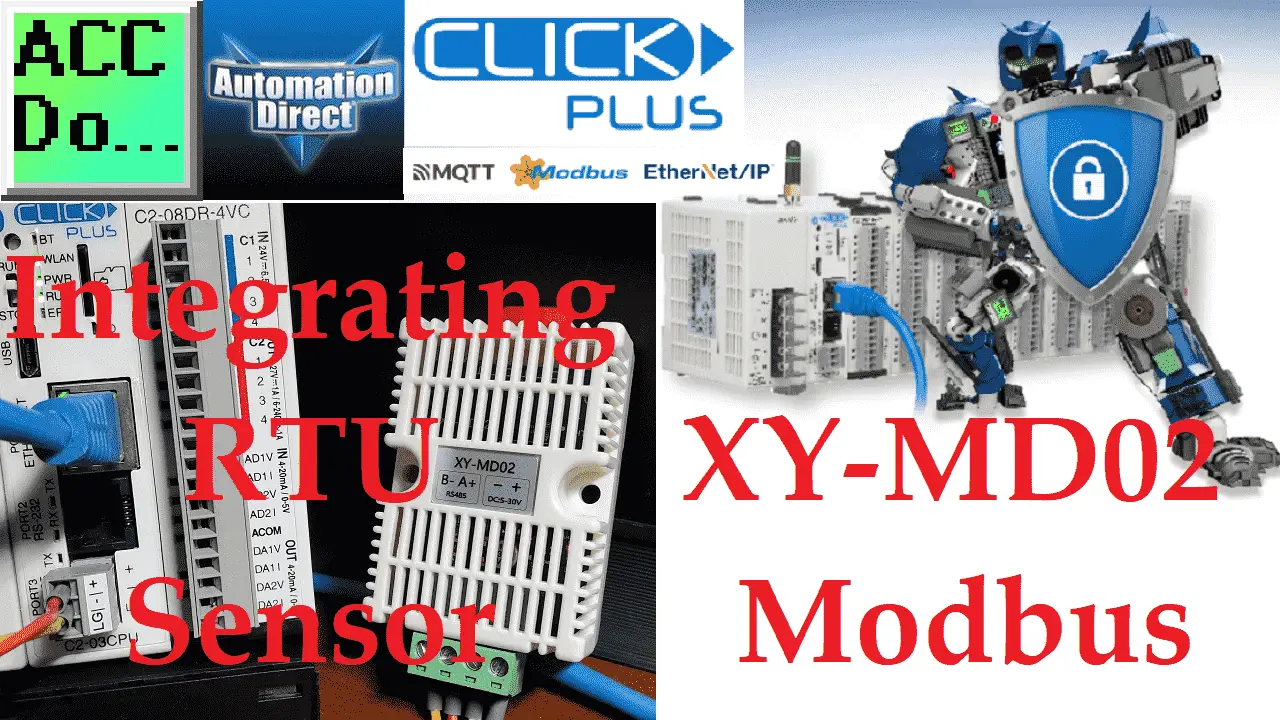

Integrating XY-MD02 Sensor Modbus RTU Click PLC

Using Modbus RTU (RS485), we will connect the XY-MD02 Temperature and Humidity Sensor to the Click PLC. The Click will be the Client (Master), and the Sensor will be the Server (Slave). This is an ideal sensor to place in a panel to ensure that the panel is within a working temperature and humidity range. … Read more