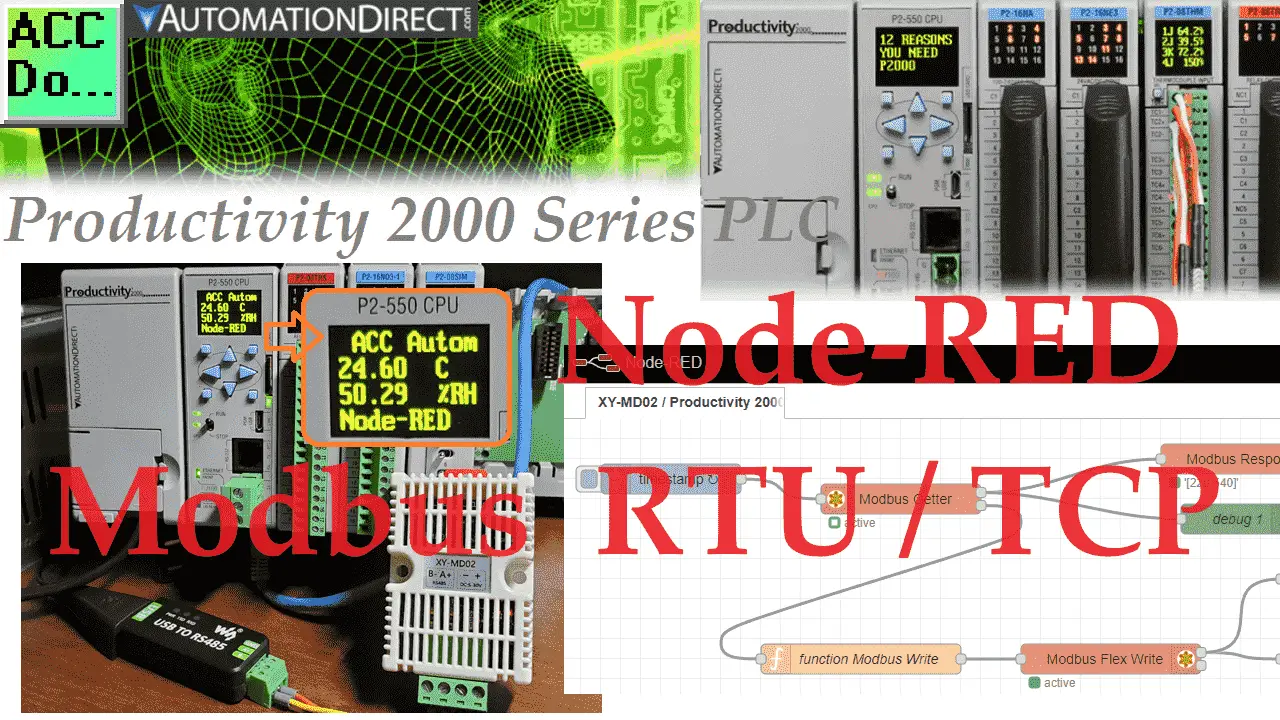

Productivity 2000 PLC Node-RED Modbus TCP

We will now look at communication between the Productivity 2000 PLC (Modbus TCP Server) and Node-RED (Modbus TCP Client). Node-RED is a powerful, adaptable HMI/SCADA (Supervisory Control and Data Acquisition) development package that uses flow programming. Minimal coding is required; you can see the program flow visually. The best thing is that the software is … Read more