Why Every Beginner Needs a PLC Simulator Now! Are you tired of feeling left behind in the industrial automation industry? As a beginner, it can be overwhelming to keep up with the latest technologies and trends. That’s why PLC simulation is more crucial than ever! We’ll explore the importance of PLC simulation and why it’s essential to get started with it right away.

We will discuss their features and the benefits they provide for you. Whether you’re a student, engineer, or just starting out in the industry, you won’t want to miss this post. So, what are you waiting for? Let’s dive in!

For beginners exploring the world of Programmable Logic Controllers (PLCs), a PLC simulator is an essential tool.

It serves as a bridge between theoretical knowledge and practical application, enabling you to build confidence, develop key skills, and make significant progress in your PLC journey before working with actual hardware.

Cost-Effectiveness – PLC Simulator

PLC hardware can be very expensive. Simulators offer beginners a chance to learn and practice programming without the high costs of physical equipment. Many software packages from Original Equipment Manufacturers (OEMs) come with built-in simulators, and there are also free or low-cost third-party options available. Why spend thousands on PLC software and then keep paying maintenance fees every year?

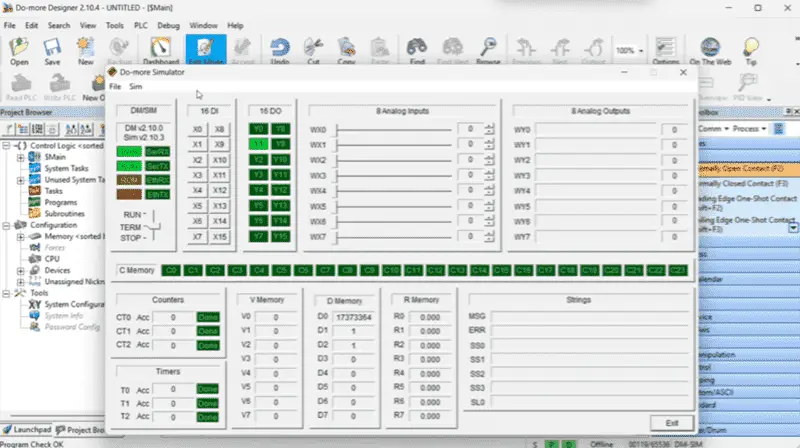

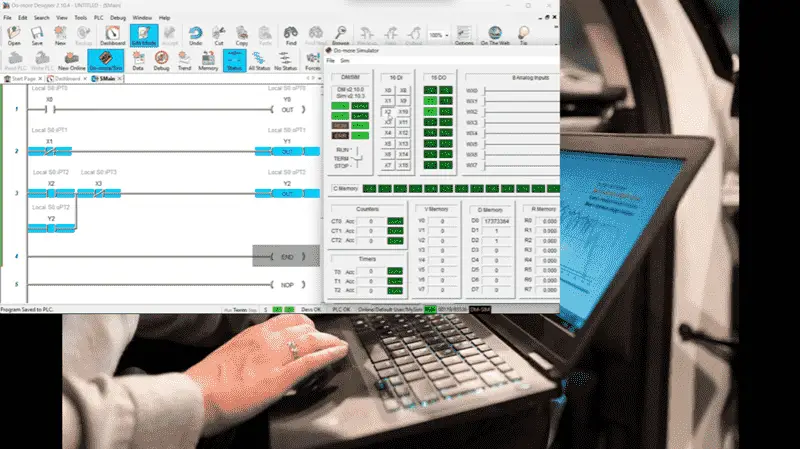

One of the most popular PLC simulators is in the Do-More Designer. This is a fully functional free package that programs in ladder logic diagrams, similar to those used by Allen-Bradley.

Safety and Risk-Free Learning

Using a simulator lets you experiment without the worry of damaging expensive equipment or creating safety risks. You can make mistakes, try out different logic setups, and learn in a safe, controlled space.

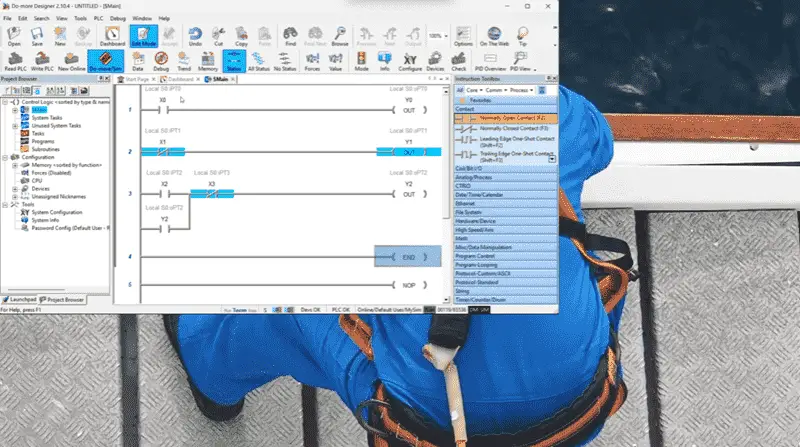

PLC programming is all about practical use, and a simulator serves as a virtual “sandbox” where you can write, test, and fix your ladder logic programs. This hands-on experience is important for understanding how PLCs work and for converting real-life problems into PLC code.

Accessibility and Convenience

You can run a PLC simulator on your personal computer, making it accessible anytime, anywhere. This eliminates the need for specialized labs or dedicated hardware, allowing for flexible learning at your own pace. You do not need to have your hardware present to test and implement your control ideas.

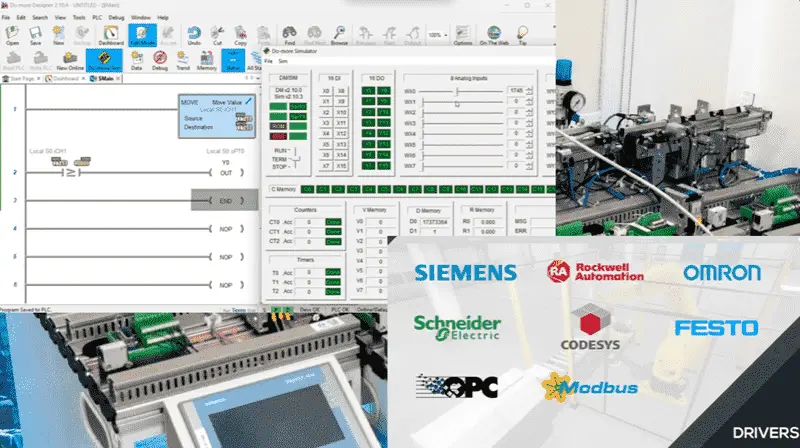

This saves you time. Many PLC simulators are designed to mimic the look and feel of actual PLC programming software from major manufacturers (like Rockwell Automation’s RSLogix or Siemens’ TIA Portal). This helps beginners become familiar with the industrial-standard tools they’ll encounter in professional settings.

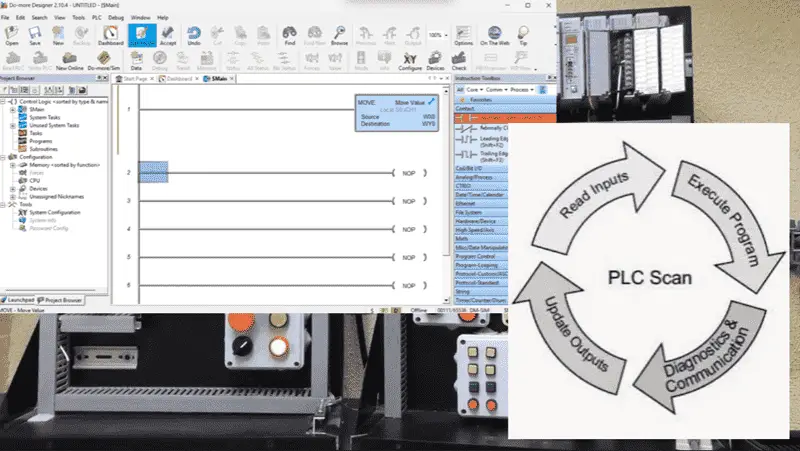

Understanding Program Execution

Simulators allow you to “go online” with the virtual PLC and observe how your program executes in real-time. You can monitor input and output responses, identify logical errors, and see the sequence of operations under various conditions. This visual feedback is invaluable for grasping the flow of control in a PLC program.

PLC simulators follow the same SCAN cycle as a physical PLC. Read inputs, execute program, communication and diagnostics, and write outputs. Solving logic is also the same. The PLC will solve the ladder logic left to right, top to bottom. The output from the previous rung is available for use by the next rung.

Troubleshooting and Debugging Skills

A key skill in PLC programming is troubleshooting. Simulators provide an excellent platform for practicing identifying and correcting errors in your logic. You can step through your program line by line, observe data values, and pinpoint where issues arise.

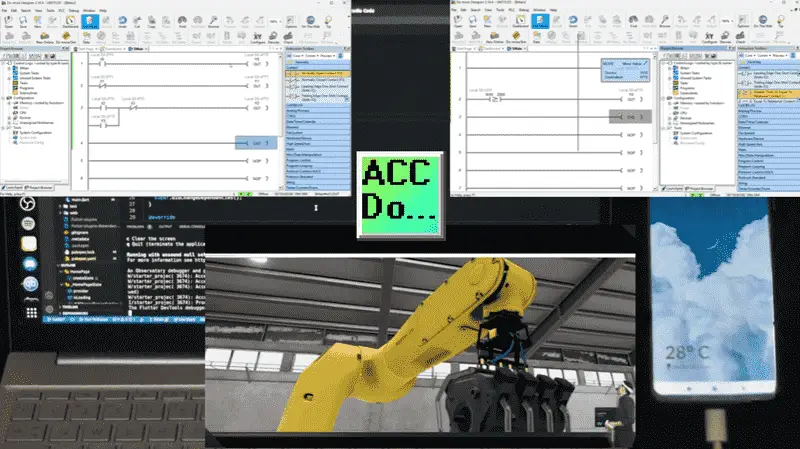

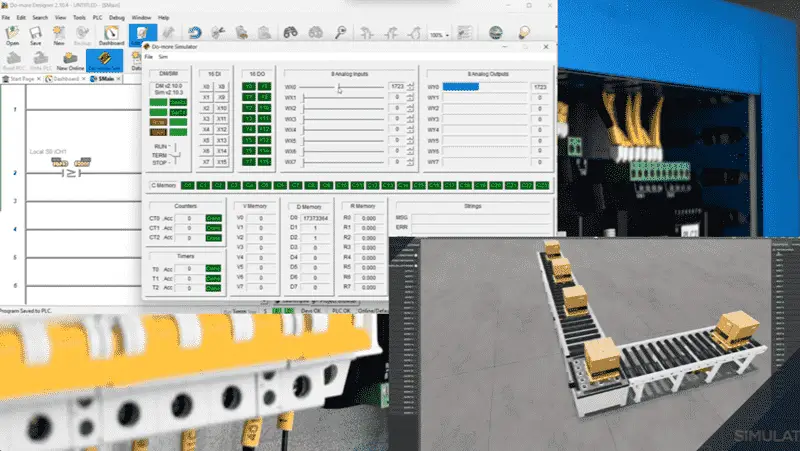

While a physical PLC might be limited in the scenarios you can realistically test, a simulator allows you to create and test a wide variety of complex conditions and sequences, including those that might be difficult or unsafe to replicate in a real-world setting. Some advanced simulators even allow you to simulate or communicate with HMI (Human-Machine Interface) interactions. This is done through the Ethernet connection on your computer. Based on this information, some PLC simulators can also integrate with 3D environments to replicate real-world systems, such as conveyor belts, elevators, or bottling plants.

Machine Simulator is a package from Nirtec that will allow you to connect your simulator or physical PLC.

A PLC simulator serves as a bridge between theoretical knowledge and practical application. It provides you with the opportunity to build confidence, develop your essential skills, and make significant progress in your PLC journey before working with actual hardware.

Watch on YouTube: Why Every Beginner Needs a PLC Simulator Now!

PLC Beginner’s Guide to PLC Programming

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. See below to receive 10% off this software. This PLC learning package includes the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning package for less than $95 USD for a single computer installation or less than $110 USD to allow access on multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.