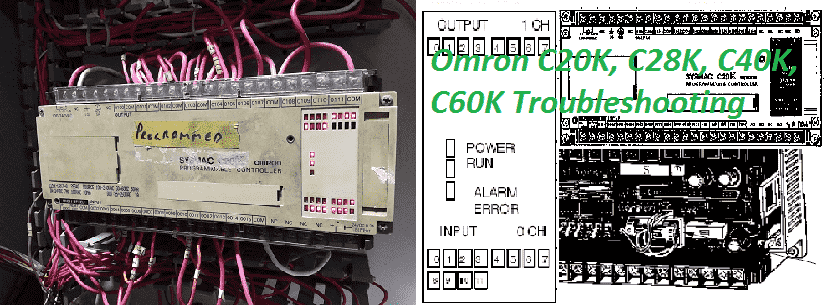

Omron C20K, C28K, C40K, C60K Troubleshooting

The Omron C20K, C28K, C40K, and C60K shoebox programmable logic controllers have been discontinued since March of 2002. These Omron ‘K’ series PLCs were popular controllers and have been in installations for over 25 years. We will take a look at this Omron PLC and review some troubleshooting techniques. Planning for the eventual fatal failure … Read more