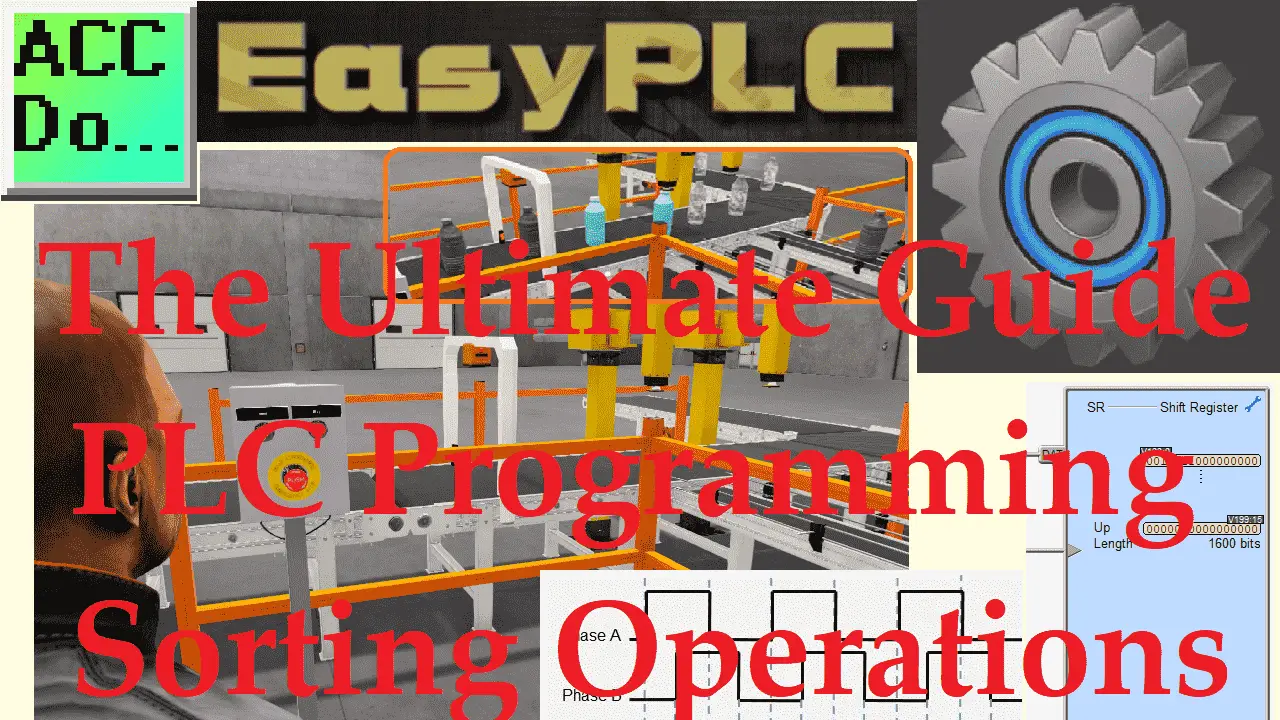

Easy Steps to Program a Click PLC Sorting System

Learn how to program a Click PLC sorting station from scratch in this comprehensive tutorial! We’ll take you through the step-by-step process of designing and programming a Click PLC sorting station, covering everything from setting up the PLC to writing the code. Whether you’re a beginner or an experienced programmer, this method is ideal for … Read more