Stop Wasting Money on PLC Training Hardware: Why Digital Twins Are Revolutionizing Industrial Automation

What if you could test your entire factory floor before spending a single dollar on equipment?

Welcome to the world of digital twins—and Nirtec’s Machines Simulator is leading the charge.

The Million-Dollar Problem Nobody Talks About

Here’s the harsh reality: Traditional PLC training and industrial automation development is broken.

Companies are spending thousands of dollars on physical training equipment that:

- Breaks down and requires costly maintenance

- Takes up valuable floor space

- Can only train one person at a time

- Puts learners at risk of damaging expensive hardware

- Can’t simulate dangerous scenarios safely

Engineers and students waste months waiting for lab access. Manufacturers burn cash testing systems that fail in production. And worst of all? One programming mistake can destroy $50,000 worth of equipment.

There has to be a better way.

Enter Machines Simulator: Your Factory in a Laptop to create or use digital twins.

What is Machine Simulator – Digital Twin

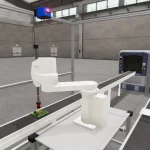

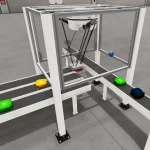

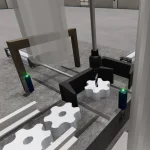

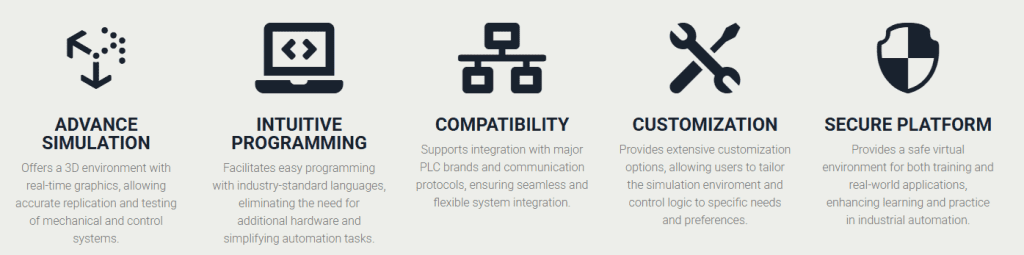

Machines Simulator is a 3D platform for designing, programming, and testing mechanical and control systems that transforms how industries approach automation (Digital Twin) —without the risk, cost, or limitations of physical hardware.

Think of it as the ultimate industrial sandbox where you can:

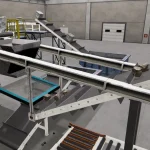

- Build anything. Choose from over 250 pre-programmed components and more than 600 ready-to-use models spanning sensors, pneumatic systems, robotics, and conveyors. Or import your own 3D models and program custom behaviors.

- Test everything. Run real-time simulations of your fully programmed setups. Speed up, slow down, or pause time to observe every detail. Monitor digital and analog I/O in real-time.

- Break nothing. Simulate dangerous scenarios, test edge cases, and push systems to failure—all without risking a single piece of equipment or human safety.

Why Industries Are Ditching Physical Labs

Manufacturers & Engineers

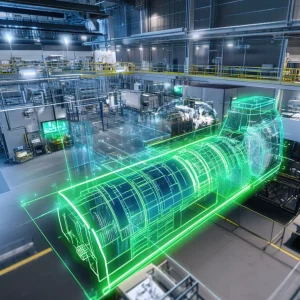

Build digital twins of any industrial system, providing a virtual replica that accurately mirrors real-world processes and behaviors. This means you can:

- Slash development costs by catching design flaws before production

- Eliminate downtime by testing maintenance procedures virtually

- Win more bids by showing clients stunning 3D simulations instead of static drawings

- Accelerate deployment from months to weeks

Educators & Students

Educational Models provides a digital twin package that brings physical model scenarios directly into Machines Simulator, overcoming the limitations of costly physical models by enabling simultaneous, risk-free learning from school or home.

Imagine teaching 30 students simultaneously—each with their own virtual factory floor. No waiting lists. No broken equipment. No limits.

Training Programs

Enables a smooth transition from theory to application, allowing trainees to practice PLC programming and process control safely and repeatedly, ideal for onboarding and continuous learning without impacting production resources.

New hires become productive faster. Experienced staff can upskill without production disruptions. Everyone learns by doing—not just watching.

The Secret Sauce: Real Industrial Tools, Zero Hardware

Here’s what makes Machines Simulator digital twin different from other “simulation” software:

- Industry-Standard Programming: Program scenarios using C# scripts or use the node-based visual programming system. Plus, it’s compatible with EasyPLC for seamless PLC integration.

- Real Hardware Integration: Connect actual PLCs, I/O modules, and automation devices. Wire external I/O directly to your PC to work with real-world inputs and outputs of your system.

- Proven Scenarios: Access over 60 pre-built and fully programmed scenarios covering solar energy, logistics, automotive, robotics, and more—from simple setups to comprehensive factory replicas.

- Multiple Programming Options: Whether you’re a beginner using node-based visual programming or an expert writing C# scripts, there’s a workflow for you.

- Virtual Reality: The Future Is Already Here

Want to take immersion to the next level? Transform simulations into fully immersive virtual reality experiences, interacting realistically with the environment. Walk through your virtual factory. Reach out and interact with machinery. Train multiple people simultaneously in the same shared VR environment. It’s not science fiction—it’s happening now.

The Numbers Don’t Lie

Organizations using digital twin technology report:

Up to 90% reduction in physical prototyping costs

50-70% faster time-to-market

30-40% improvement in training efficiency

Zero equipment damage during testing phases

Nirtec’s software is trusted by 500+ companies worldwide who understand that the future of industrial automation isn’t about buying more hardware—it’s about simulating smarter.

Who Needs Machines Simulator Digital Twin?

You should consider this if you:

- Teach industrial automation or PLC programming

- Develop or maintain automated manufacturing systems

- Need to train operators without production downtime

- Want to test dangerous scenarios safely

- Are you tired of waiting for lab equipment access

- Need to demonstrate systems to clients before building

- Want to reduce equipment damage from testing

Getting Started Is Easier Than You Think

The Machines Simulator Suite is compatible with Windows 11 and Windows 10, requiring at least 8GB of memory. Most modern computers can run it.

Plus, with lifetime licensing options and both standalone and cloud-based licenses available, you can choose what works for your needs.

The Bottom Line

Stop thinking of simulation as a “nice to have” educational tool. Digital twins enhance decision-making, minimize downtime, and improve overall operational efficiency, offering invaluable insights and control over complex systems in a safe and adaptable environment.

Programming a PLC no longer requires a full lab of hardware. Today, you can open your laptop and dive into automation from anywhere. Test logic, trigger sensors, watch actuators respond—no wires, no risks, no limits.

The question isn’t whether you can afford digital twin technology. The question is: Can you afford not to use a digital twin?

Ready to transform your approach to industrial automation? Discover how the Machines Simulator digital twin can revolutionize your training, development, and manufacturing processes. To learn more or see a demo, click here. Click here to learn the five steps to PLC program development.

The best way to build the future is to simulate it first.

Watch on YouTube: What if DIGITAL TWINS Could Transform Your Factory?

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. This allows you to make a digital twin. See below to receive 10% off this software. This PLC learning package contains the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning digital twin package for less than $95 USD for a single computer installation or less than $110 USD to allow access on multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.