The purpose of a ramp soak profile is to make gradual, controlled changes in temperature (Ramp), followed by a temperature hold (Soak) period.

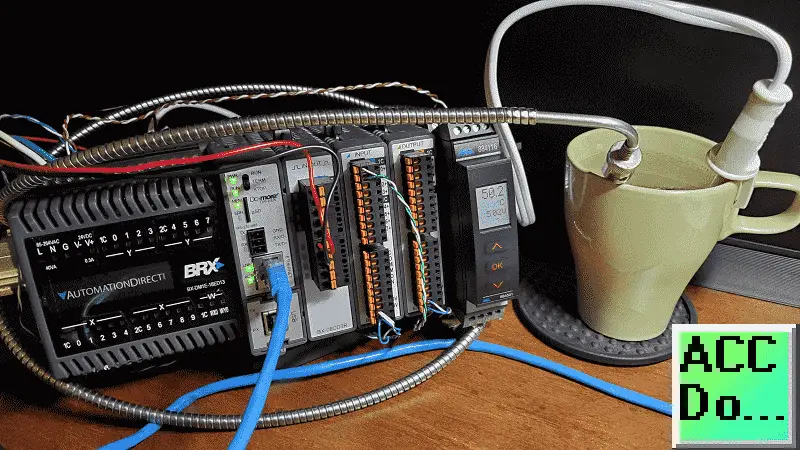

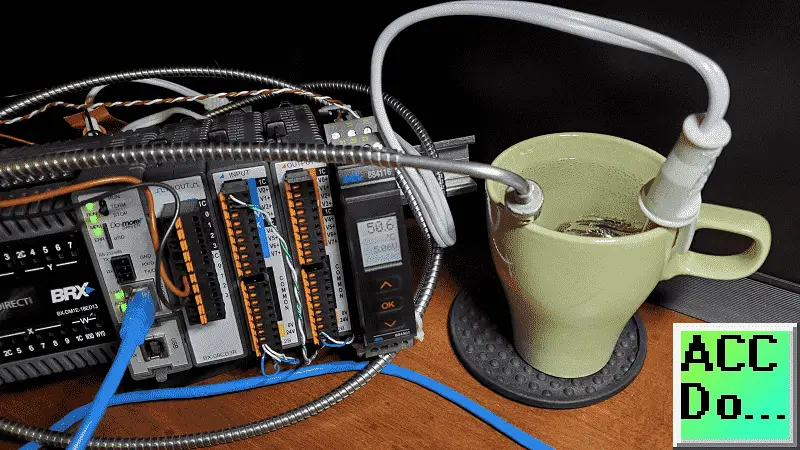

We will be using our Do-More Proportional-Integral-Derivative PID Instruction with PWM output that we looked at last time to apply the ramp/soak profile. This will be done on the BRX Do-More PLC.

Using the immersion heater in a cup of water to keep the temperature at a constant value, we will be adjusting the profile of the temperature as we increase the setpoint (Ramp) and hold that set point for a predetermined time. (Soak) We will then decrease that temperature back to the original setting. (Ramp)

We will be modifying our existing program from our PID with PWM Output post. Let’s get started.

Previously in this BRX Do-More series PLC, we have discussed:

System Hardware – Video

Unboxing – Video

Installing the Software – Video

Establishing Communication – Video

Firmware Update – Video

Numbering Systems and Addressing – Video

First Program – Video

Monitoring and Testing the Program – Video

Online Editing and Debug Mode – Video

Timers – Video

Counters – Video

High-Speed IO – Video

Compare Instructions – Video

Math Instructions – Video

Program Control – Video

Shifting Instructions – Video

Drum Instruction – Video

Serial Communication – Modbus RTU to Solo Process Temperature Controller – Video

Data Logging – Video

Email – Text SMS Messaging Gmail – Video

Secure Email Communication Video

AdvancedHMI Communication – Modbus TCP – Video

Analog IO – System Configuration – Video

HTTP JSON Instructions – Video

Analog Dusk to Dawn Program – Video

INC DEC 512 Registers for DMX512 – Video

PID with PWM Output – Video

Our entire series can be found here.

The programming software and manuals can be downloaded from the Automation Direct website free of charge.

Watch the video below to see the Do-More PID Ramp Soak Instruction in action on our BRX Do-More PLC.

The thermocouple (feedback) input, analog input setup, and wiring can be reviewed in the following post. BRX Do-More PID with PWM Output – Video

We will be adding to this existing program at the beginning of the main program section.

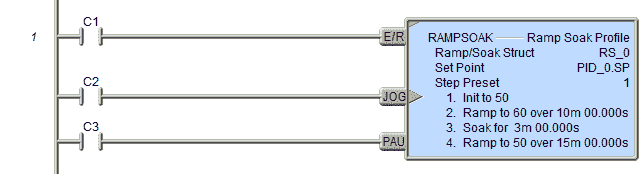

BRX Do-More RAMPSOAK – Ramp Soak Profile

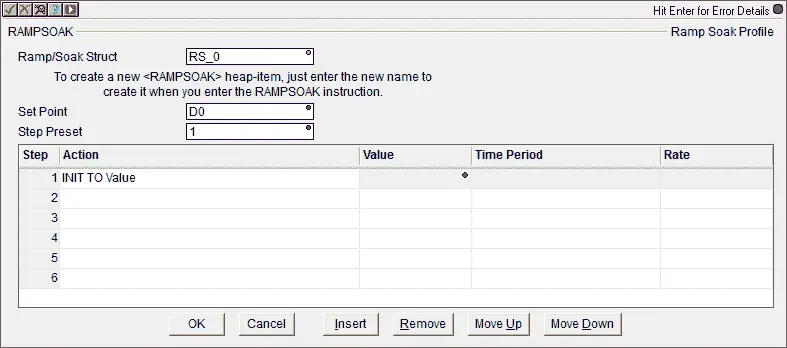

The Ramp / Soak Profile (RAMPSOAK) instruction contains a table of sequential operations that will move the user-specified setpoint value through a predefined set of values at prescribed time intervals. A Ramp / Soak Profile can contain from 1 to 50 individual steps. Each of the individual steps is executed sequentially to modify the value of the SetPoint variable.

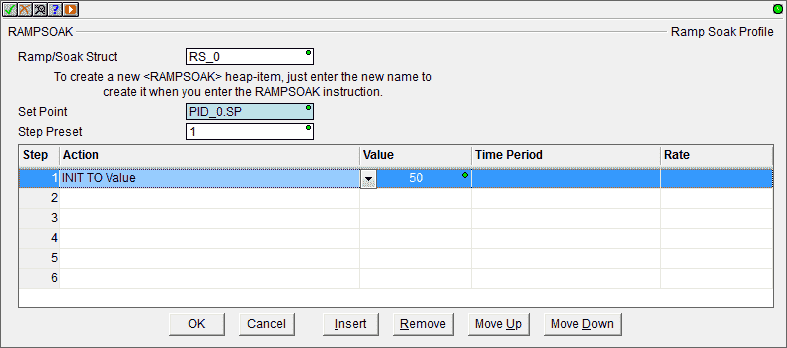

We will leave the Ramp/Soak Structure (Heap-item) as the default RS_0.

Our Set Point will be PID_0.SP from our previous post.

The INIT TO Value will be set for 50 degrees Celsius. This makes the Set Point equal to the specified value. We can use a variable or constant value.

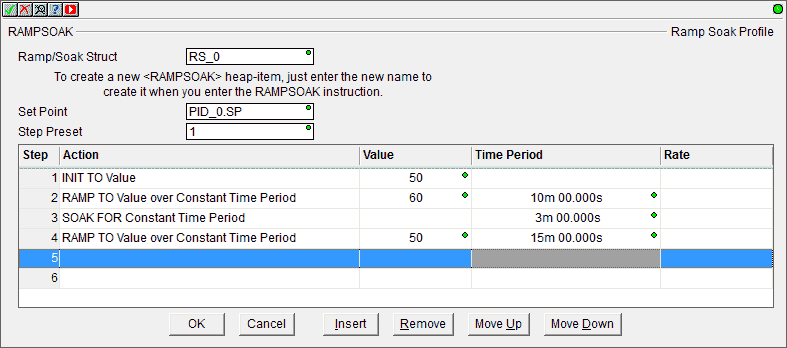

There are three types of step functions to choose from: one that sets the SetPoint to a fixed value (INIT), one that leaves the Set Point value unchanged for a period of time (SOAK), and one that linearly changes the Set Point value over a period of time (RAMP).

The SOAK for Constant Time Period or Variable Time Period will not modify the Set Point for the Time Period (in milliseconds) which is specified by either a constant (fixed) value or a value in a readable numeric location.

The ‘RAMP to Value over Time’ or ‘ADJUST by Value over Time’ step types will increase or decrease the Set Point linearly across the specified Time Period to the Target Value.

The RAMP to Value over Constant Time Period or Variable Time Period moves the SetPoint from its current ABSOLUTE value to the ABSOLUTE target Value. The target value can be any constant value or any readable numeric location.

The ADJUST BY Value over Constant Time Period or Variable Time Period changes the Set Point by an amount RELATIVE to the current SetPoint.

The ADJUST BY Value over Constant Time Period or Variable Time Period changes the Set Point by an amount RELATIVE to the current SetPoint. The target value can be any constant value or any readable numeric location.

The ‘RAMP to Value at Rate’ or ‘ADJUST by Value at Rate’ will control the rate at which the changes to the setpoint are applied.

The RAMP to Value at Rate / Second or Rate / Minute or Rate / Hour moves the SetPoint from its current ABSOLUTE value to the ABSOLUTE target Value.

The ADJUST BY Value at Rate / Second or Rate / Minute or Rate / Hour changes the Set Point by an amount RELATIVE to the current SetPoint. The target value can be any constant (fixed) value or any readable numeric location.

Our ramp soak profile will have 4 steps. The initial one will be a set value of 50 degrees Celsius. We will then RAMP TO the Value of 60 over a Constant Time Period of 10 minutes. Maintaining a temperature of 60 for 3 minutes will be our SOAK time. Finally, we will RAMP TO the Value of 50 over a Constant Time Period of 15 minutes.

Our ramp soak profile instruction has three inputs.

The first input (E/R) is the ENABLE / RESET input. If the input logic is ON, the Ramp / Soak will start sequencing through the steps, beginning with step 1. When this input logic is OFF, the Ramp / Soak will reset the instruction by resetting the current step to the Step Preset value (usually 1).

The second input (JOG) is the JOG input. This is edge-triggered Closed meaning that each time this input logic transitions from OFF to ON execution will manually move to the next step in the Ramp / Soak Profile, regardless of whether the current step has completed or not.

The third input (PAU) is the PAUSE input. When the input logic is ON, this input will freeze the execution of the RAMPSOAK Profile in the current step. Execution will continue from the point it was paused when the input logic is OFF.

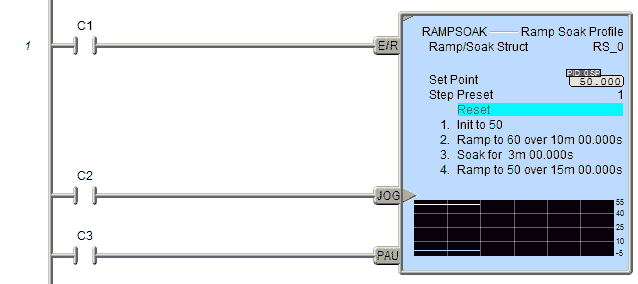

Status Monitoring RAMPSOAK Instruction – BRX Do-More

When monitoring the status of our Ramp Soak Profile instruction, you will see the steps of our profile. The highlighted in blue shows the current step at which the instruction is on. In our case above it has been reset, since the first input is off. This is a good tool to monitor your profile.

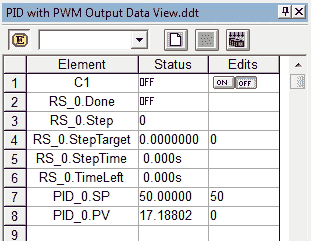

We can also use the Data View to monitor our heap structure RS_0.

Watch the video below to see the ramp soak profile instruction in action on our BRX Do-More Series PLC.

You can download the program here.

BRX (Do-More) Series PLC from Automation Direct – Power to deliver

Overview Link (Configure and purchase a system)

Manuals and Product Inserts (Installation and Setup Instruction)

Do-More Designer Software v2.0.3 (Free Download Link) – The software will contain all of the instruction sets and help files for the BRX Do-More Series PLC.

Watch on YouTube: BRX PLC PID Ramp Soak Profile

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.